Novel logistics distribution device

A new type of logistics distribution technology, applied in the directions of covers with auxiliary devices, sealing parts with auxiliary devices, packaging, etc., can solve the problems of economic loss, damage to items, bumps of items, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

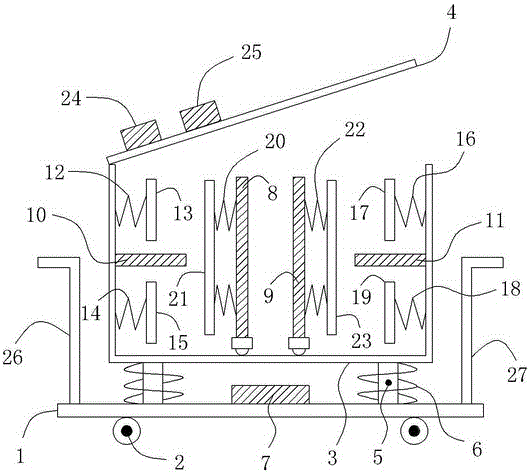

[0013] Such as figure 1 As shown, a new type of logistics distribution device includes a base 1 and a walking wheel 2 located at the bottom of the base 1, a distribution box 3 is provided above the base 1, a box cover 4 is provided on the top of the distribution box 3, and a box cover 4 is provided on the top of the distribution box. A plurality of vertically arranged bottom telescopic rods 5 are also connected between the bottom end of the base 1 and the top end of the base 1, and a bottom coil spring 6 is also sleeved outside the bottom telescopic rods 5, and a limiter is also provided on the base 1 at the same time. Block 7; the inside of the distribution box 3 is respectively provided with a vertically arranged left partition 8 and a right partition 9, and the front side wall and the rear side wall of the distribution box 3 are respectively provided with front strips extending left and right in the horizontal direction. Through holes and rear strip-shaped through holes (no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com