Inner frame of bushing of automobile crossmember

A technology of inner skeleton and ingot, which is applied in the direction of suspension, vehicle parts, cantilever mounted on pivot, etc., can solve the problems of poor stamping resistance, easy aging and deformation, etc., to improve load-bearing performance, strengthen supporting capacity, and guarantee The effect of stress intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

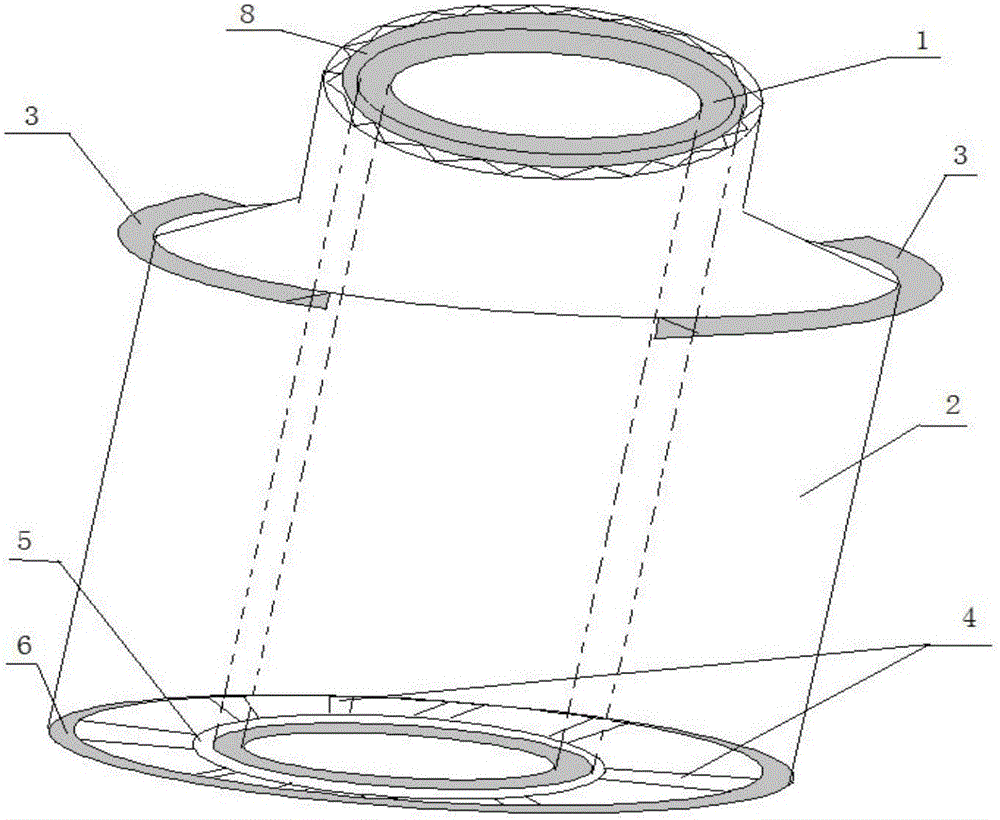

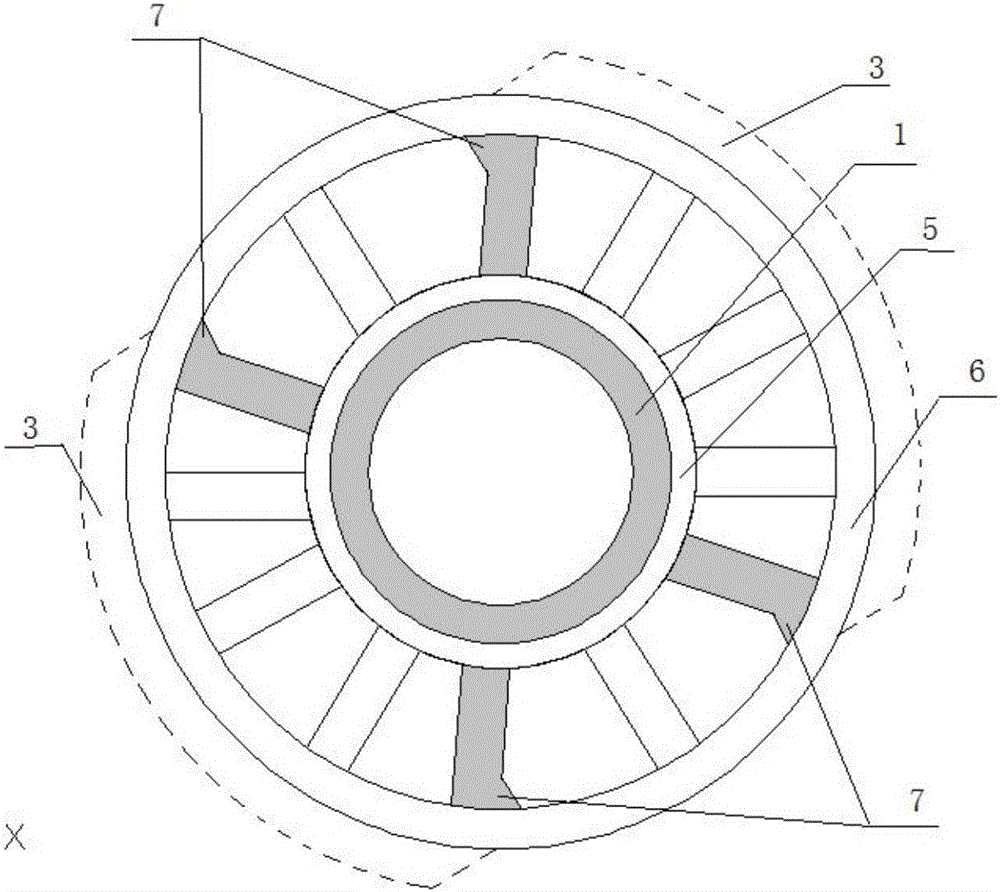

[0012] The technical solutions in the embodiments of the present invention will be fully and clearly described below in conjunction with the drawings in the embodiments of the present invention.

[0013] see Figure 1-2 , the present invention provides a technical solution for the inner skeleton of the automobile ingot beam bushing: it includes a skeleton tube 1 and a skeleton 2, the skeleton tube 1 is a cylindrical tube structure, and the skeleton 2 is provided with a coaxial inner tube 5 and an outer tube 6. The inner tube 5 and the outer tube 6 are connected by a plurality of support blocks 4, the inner tube 5 is the same length as the bone tube 1, and the outer edge of the upper end of the outer tube 6 is provided with a flange 3, The flange 3 is symmetrically distributed left and right, the inner tube 5 is tightly sleeved on the bone tube 1, and the support block 4 inside the outer tube 6 corresponding to the gap position of the symmetrically distributed flange 3 is also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com