Film pasting and bending mechanism

A bending mechanism and film sticking technology, applied in the directions of layered products, lamination auxiliary operations, lamination, etc., can solve the problems of inaccurate positioning, poor film sticking effect, and the protective film cannot be closely attached to the product, etc., and achieves easy operation. , good folding effect, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

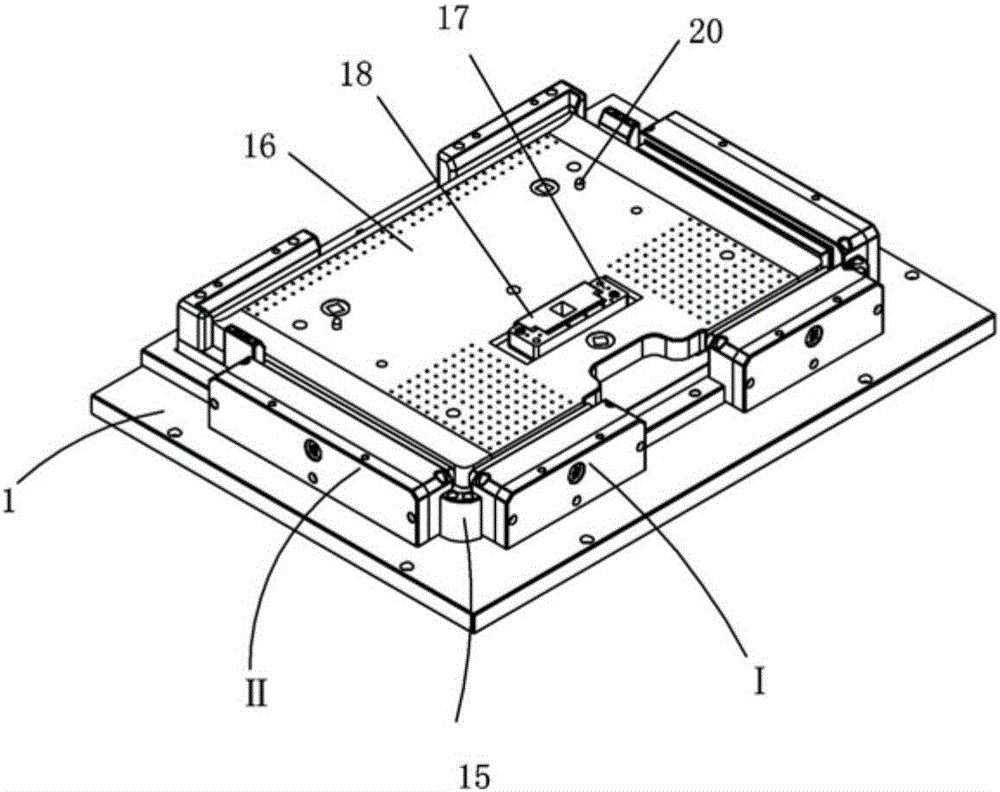

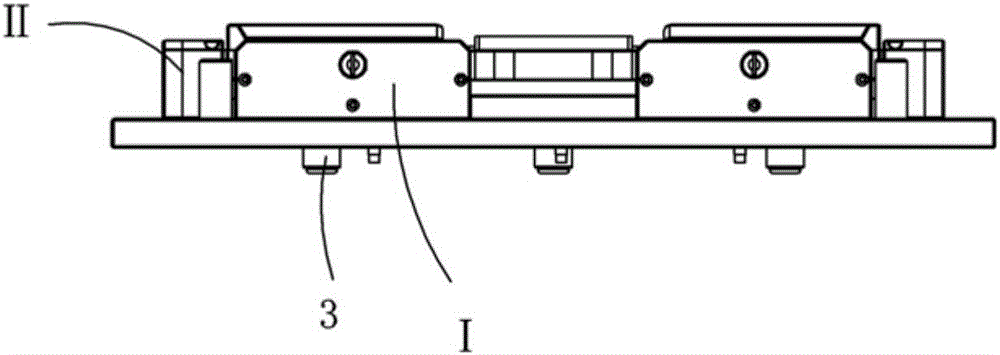

[0027] Examples, see attached Figure 1-9 , a film bending mechanism, including a base plate 1, a suction plate seat plate 2 is movably connected to the base plate, five sets of linear bearings 3 are installed on the base plate, and a set of guide columns 4 is movably installed on each set of linear bearings, And each group of guide pillars is provided with an elastic part c5, and the suction plate seat plate is installed on five groups of guide pillars. In this embodiment, the bottom plate 1 is a flat plate structure, and the bottom plate is provided with a through groove 6 for passing through the vacuum air pipe, so that the vacuum air pipe can be connected to the vacuum suction plate. The through groove includes two sets of round through grooves 601 and two sets of square through grooves 602, two sets of round through grooves are respectively located on the left and right sides of the rear of the bottom plate, and two sets of square through grooves are arranged front and ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com