Portable oil seal press-fitting device

A press-fitting device and a portable technology, which is applied in the field of assembly tooling, can solve the problems of affecting the position of the oil seal hole, the inapplicability of the press-fitting machine, and poor coaxiality of the press-fitting, etc. Good degree of accuracy, ensuring the coaxiality of the oil seal assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

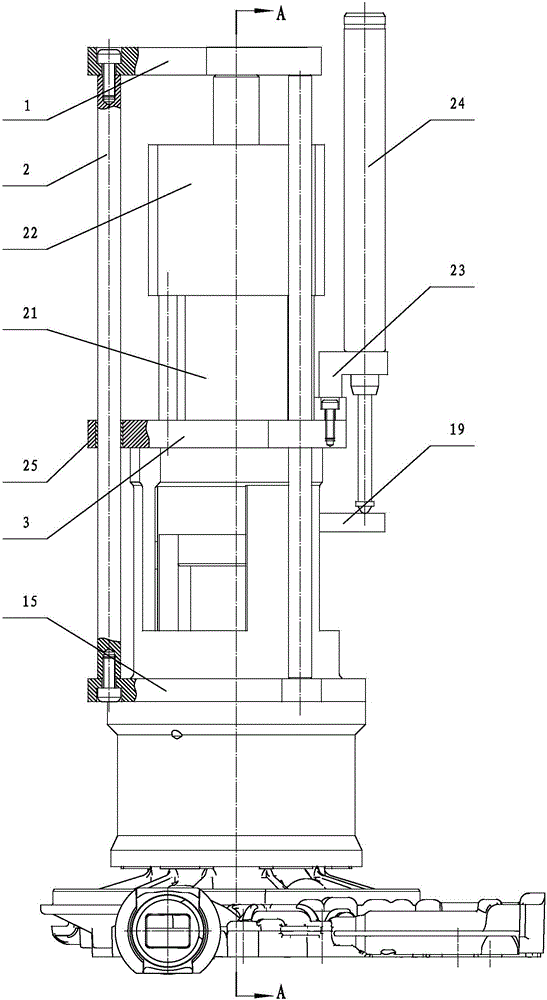

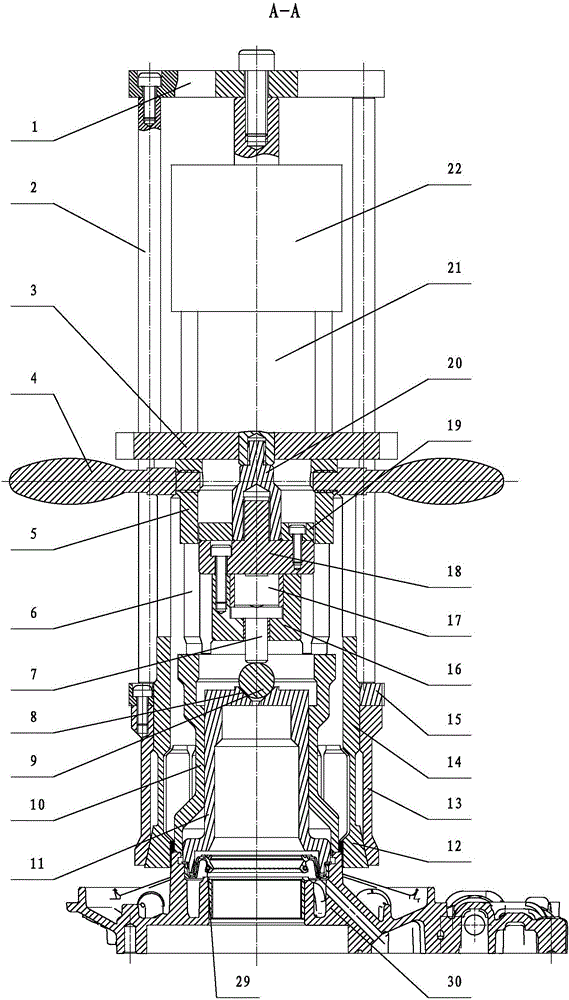

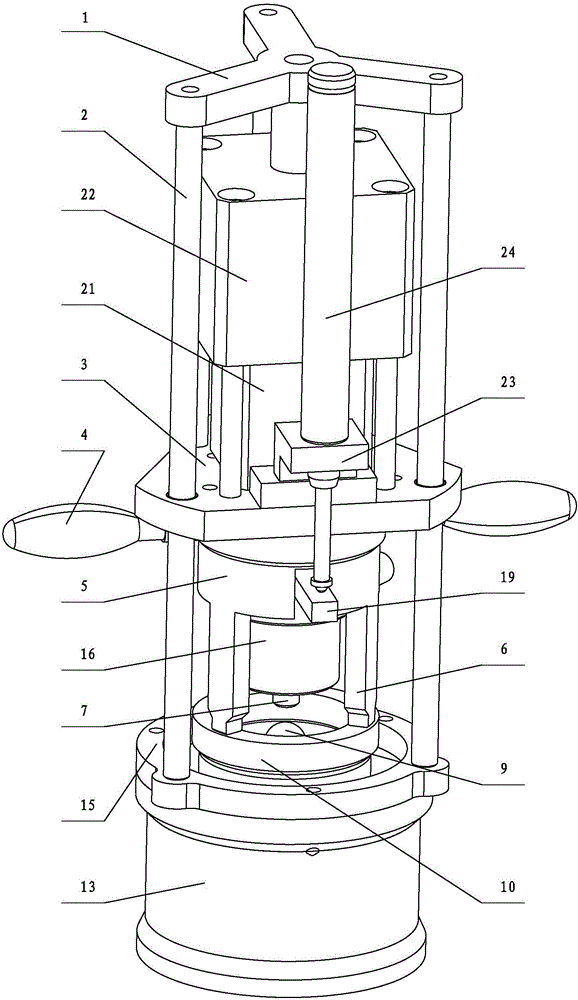

[0032] Depend on Figure 1 to Figure 7It can be seen from the schematic structural diagram of the portable oil seal pressing device of the present invention that it includes a connecting plate 3, a positioning mechanism, a locking mechanism, a pressing mechanism and a driving power mechanism, and the positioning mechanism is detachably connected in the locking mechanism And be positioned at the below of pressure head push rod 7 in the press-fitting mechanism, and the lower end of positioning mechanism is connected with transmission oil pump assembly 30 to be press-fitted, and described locking mechanism and press-fitting mechanism are all connected with drive power mechanism and Each is independently controlled and driven by the driving power mechanism. The driving power mechanism is connected above the connecting plate 3 , and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com