Adjustable-height portal frame welding machine

A gantry, welding machine technology, applied in the characteristics of welding rods, welding equipment, arc welding equipment, etc., can solve the problems of rising economic costs, waste of electric energy, low work efficiency, etc., to achieve a high degree of automation, energy saving, contact point many effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

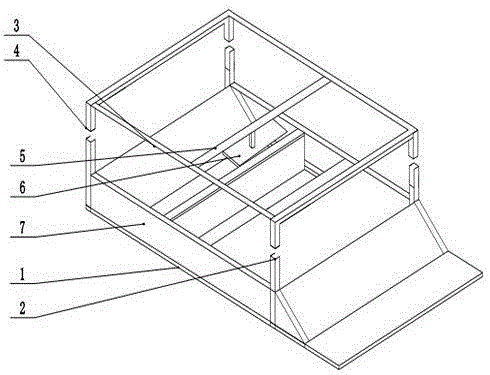

[0014] Such as figure 1 As shown, a height-adjustable gantry welding machine is characterized in that: it includes a base 1 and a frame installed on the base 1; the frame includes a column 2 and a hanger installed on the column 2; the hanger It is formed by connecting two U-shaped crossbeams 4 through two long rods 3. The middle parts of the long rods 3 are provided with slide rails, and a moving beam 5 is connected between the slide rails. Pad 6; multiple welding heads are connected to the pad 6; the column 2 is four, and the upper part of the column 2 is a hollow structure, and a coaming plate 7 is connected between the lower parts of the column 2, and the U-shaped The two ends of the crossbeam 4 are provided with short posts matching the hollow size of the column 2; the frame is also equipped with a chain conveyor. A straight rack 15 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com