Phase-change material rod

A phase change material, one-sided technology, applied in electrochemical generators, electrical components, circuits, etc., can solve the problems of poor insulation, low flame retardant performance, low structural strength, etc., to solve the problem of poor insulation performance, improve performance, improve The effect of structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments of the present invention will be described in detail below.

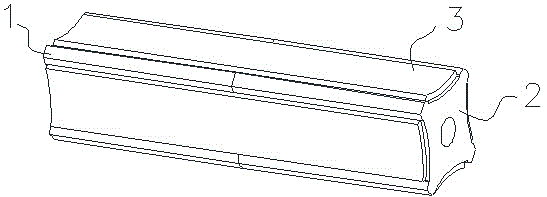

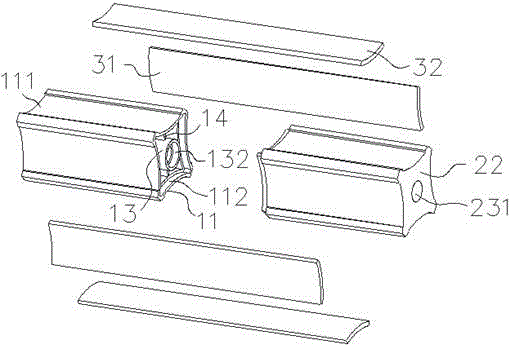

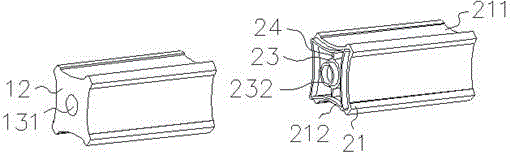

[0017] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a phase change material rod according to the present invention is composed of a first shell 1, a second shell 2, a thermally conductive silicone sheet 3 and a phase change material 4. The first housing 1 and the second housing 2 are made of thermally conductive, insulating and flame-retardant materials.

[0018] Such as figure 2 with image 3 As shown, the first housing 1 is a housing with one side closed and one side open. The housing is mainly composed of four circular arc walls 11, a flat wall 12 and a cylindrical wall 13. The four arc walls 11 are parallel to each other and symmetrically connect. The plane wall 12 and the four arc walls 11 are connected, and the space enclosed by the four arc walls 11 is closed at a single end. The cylindrical wall 13 is arranged in the middle surrounded by the four circular arc walls 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com