Mini oscillation blending device

A kind of mixing and mini technology, applied in the direction of shaking/oscillating/vibrating mixer, mixer, dissolving, etc., can solve the problems of complex structure, high cost, high noise, etc., to achieve compact size, increase service life, stable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

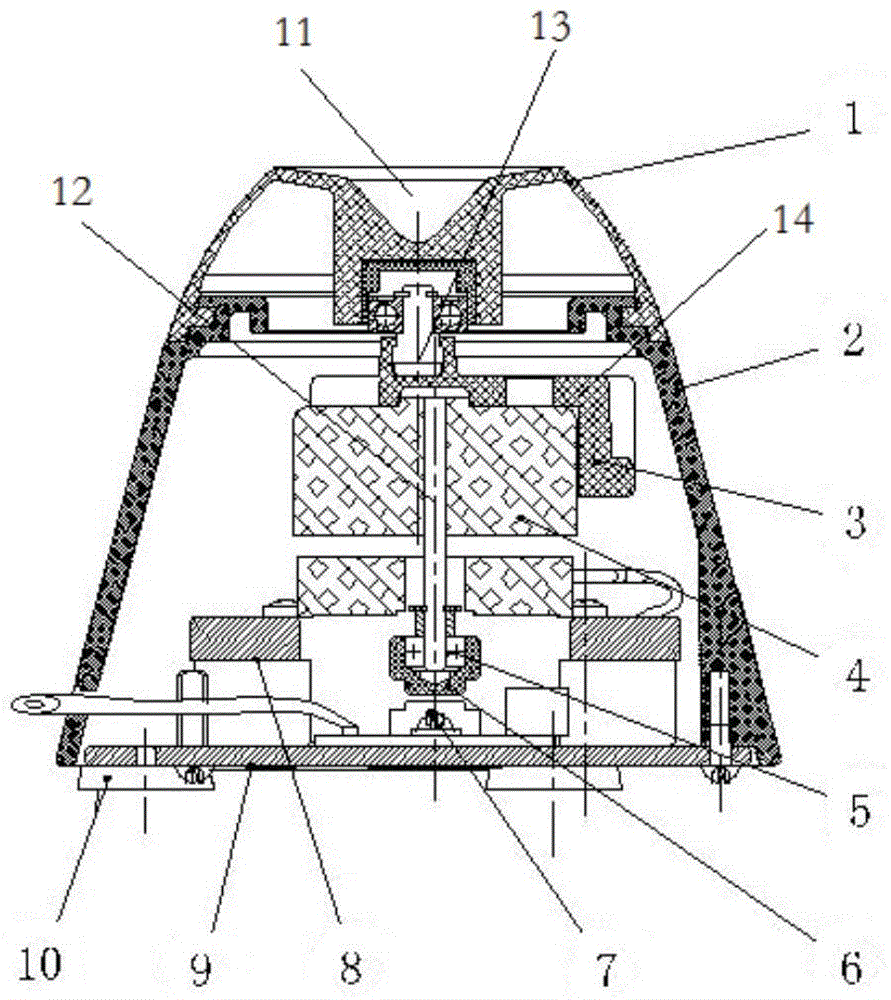

[0026] The motor shaft 12 of the outer rotor motor 4 is provided with a movable distance of 1-3 mm in the vertical direction, and the lower end of the motor shaft 12 is connected to the spring pressing cover 6 through the bearing 5. When the motor shaft 12 is stressed, it moves downward and the spring pressure The lower end of the cover is in contact with the jog switch 7 to start the instrument; the spring cover 6 is stationary all the time when the outer rotor motor 4 rotates at a high speed.

[0027] Through the control of the jog switch, the ingenious combination of the jog switch and the spring cover can make the motor jog, and the jog switch can also be connected with an external operation button to facilitate the operation of the jog switch.

[0028] Through the rotation of the rotating shaft in the motor, the eccentric mechanism rotates rapidly around the middle of the working gasket. Due to the problem of center of gravity offset, the entire supporting shell and the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com