Shearing device

A shearing device and blade technology, which is applied in the direction of shearing devices, shearing machine accessories, shearing machine equipment, etc., can solve problems such as high work intensity, low work efficiency, and potential safety hazards, so as to improve work efficiency and reduce work costs. Strength, the effect of realizing high-altitude operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

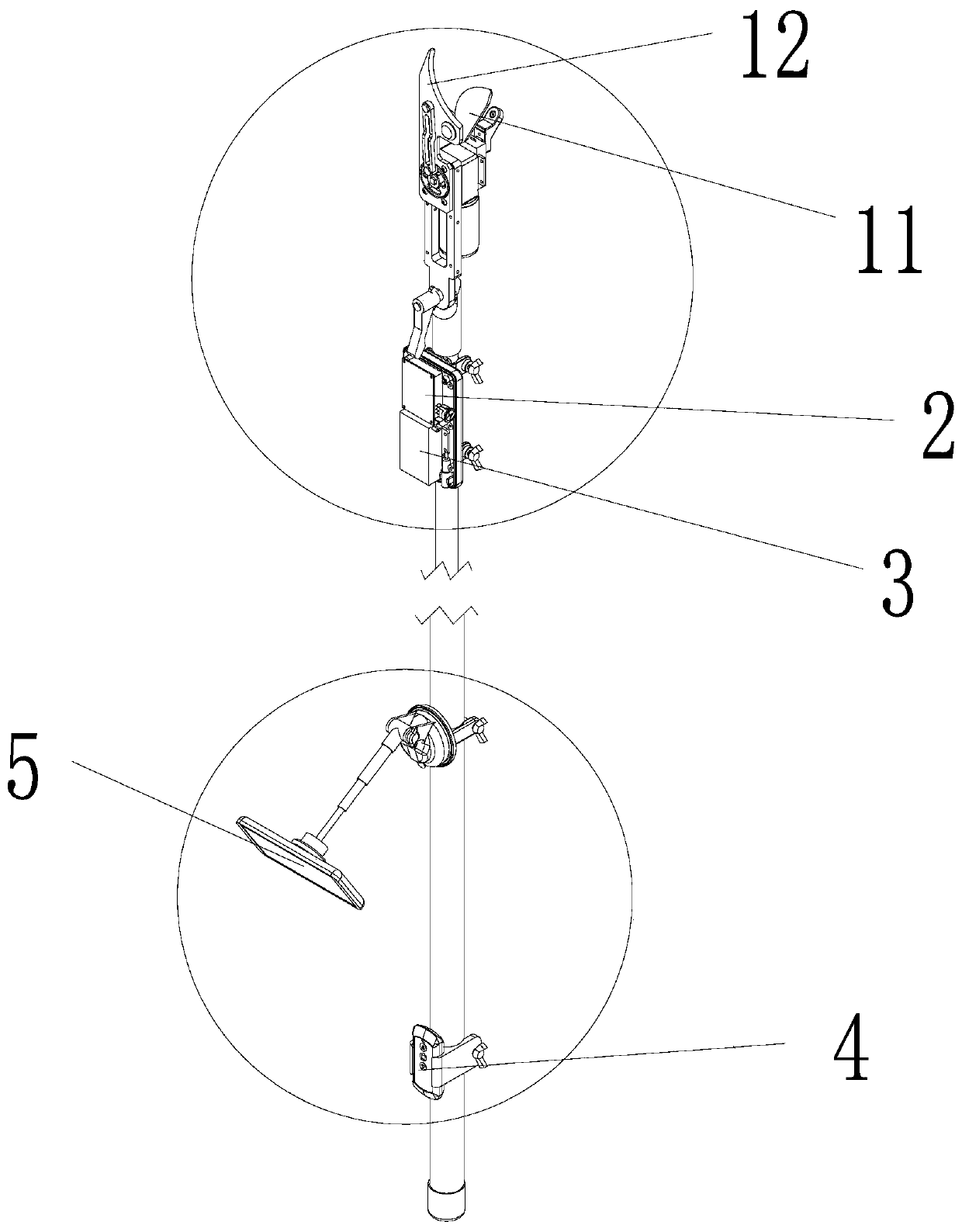

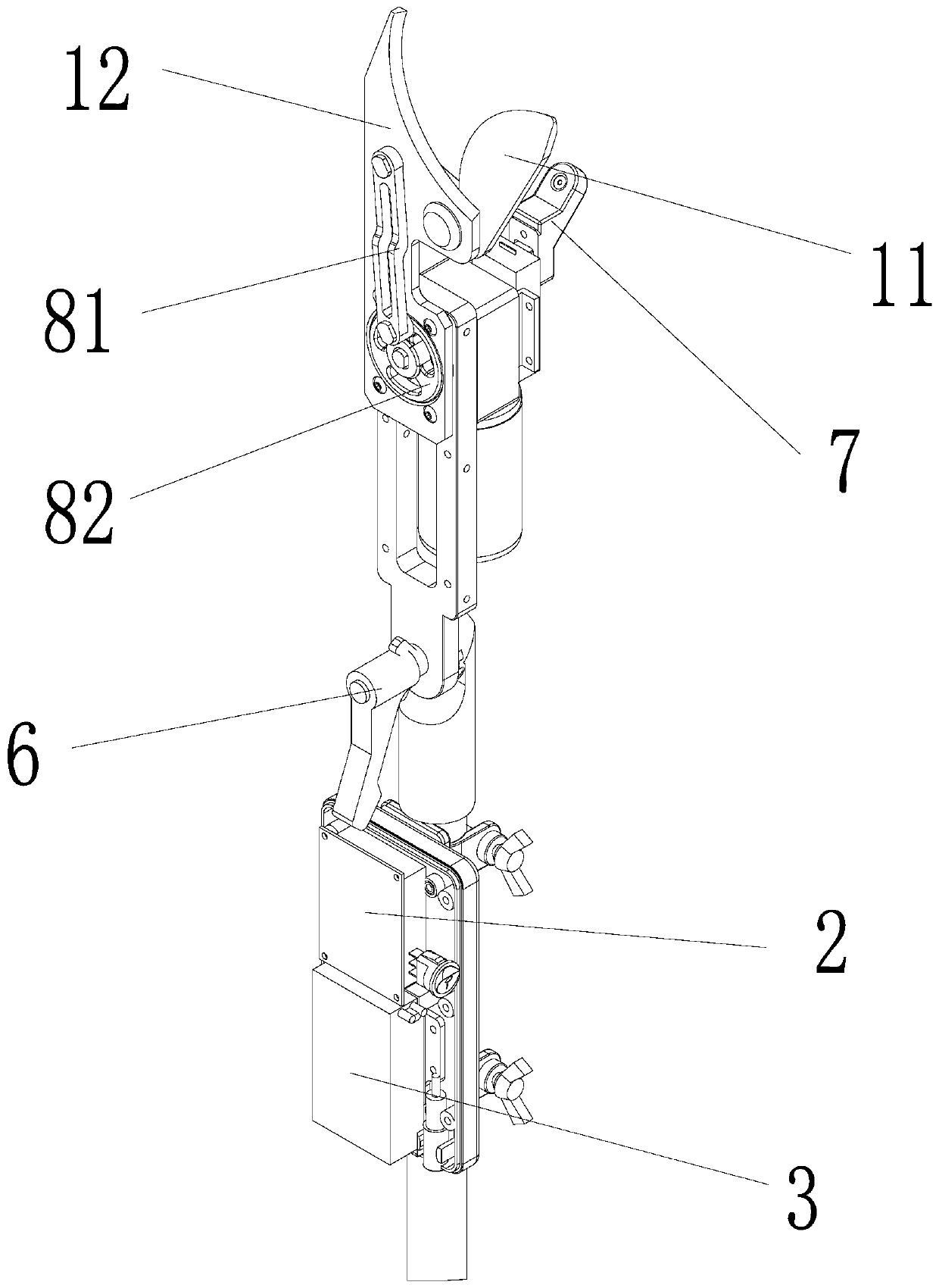

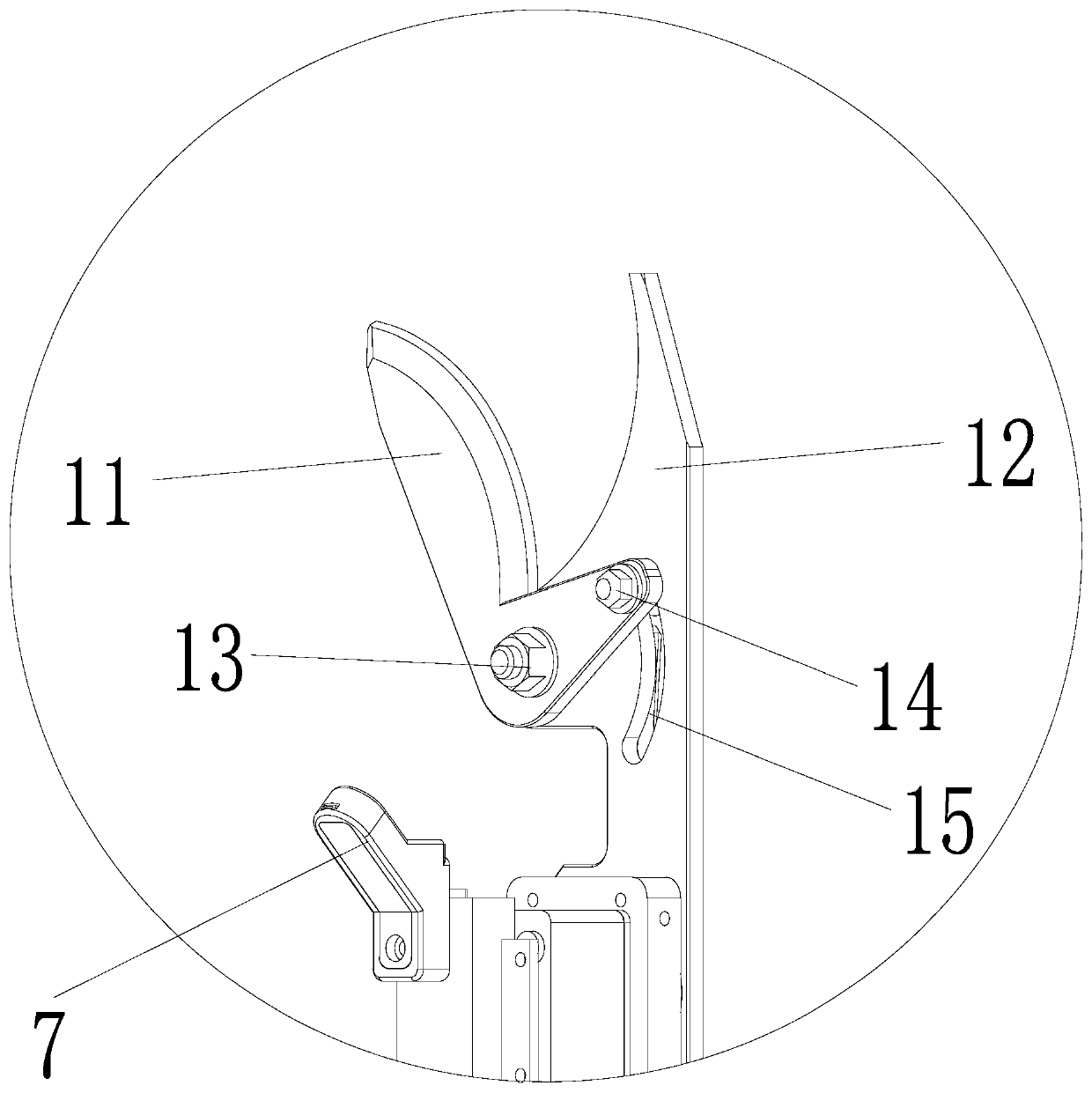

[0020] A shearing device, refer to Figures 1 to 4 , including a cutting module and a control module; the cutting module includes a first blade 11 and a second blade 12; the first blade 11 is rotationally connected to the second blade 12;

[0021] It also includes a linkage mechanism that drives the first blade 11 to rotate; the control module includes a power output mechanism, and the power output mechanism is connected to the linkage mechanism; the control module includes a control board 2 and a control switch, and the control board 2. Connect the power output mechanism; the power output mechanism, the control panel 2 and the control switch are all connected to a power supply 3, the control switch is turned on, and the power output mechanism, the control panel 2 and the control switch are all powered on; The control board 2 sends an activati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com