Supercharger device with variable geometry turbine

一种增压器、几何的技术,应用在机械设备、燃气轮机装置、机器/发动机等方向,达到优化调整、优化影响流动、加快响应行为的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

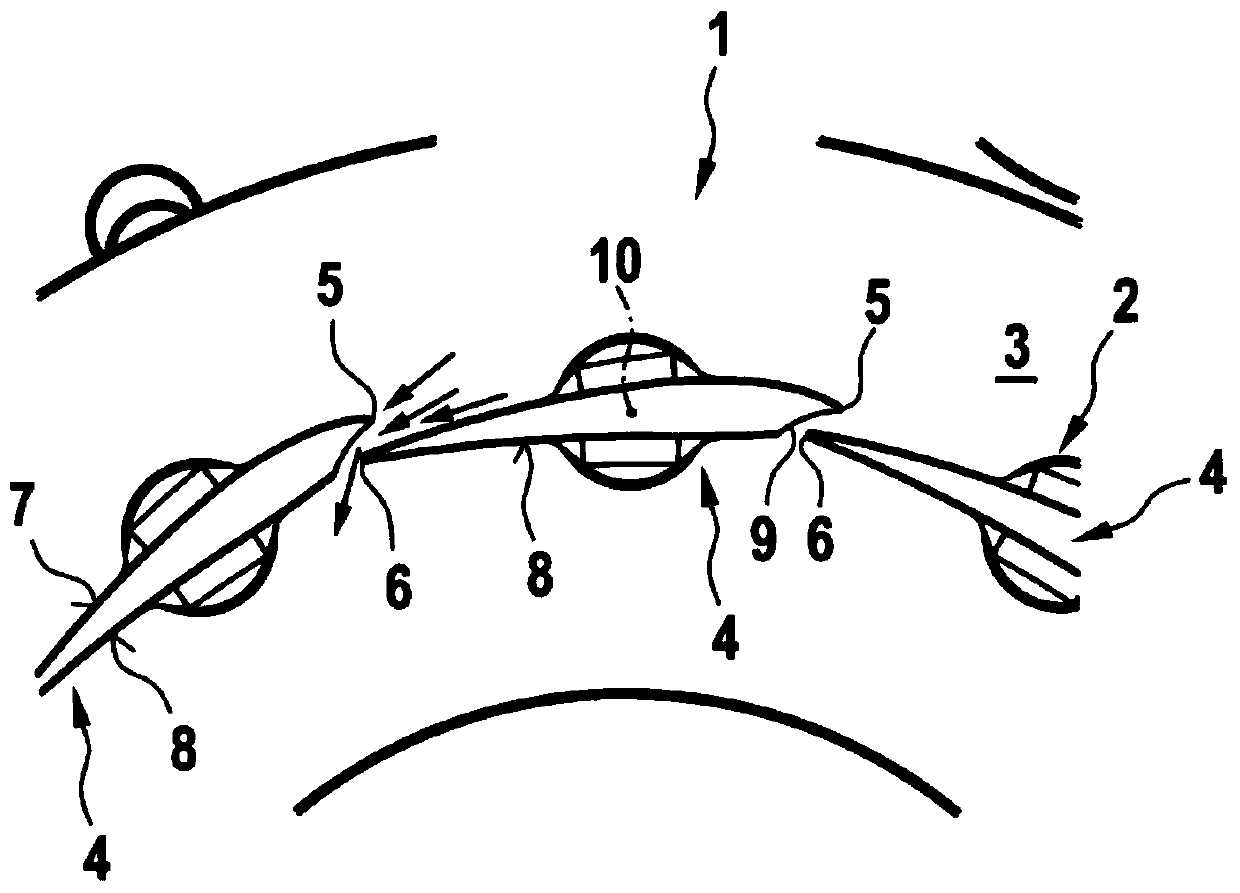

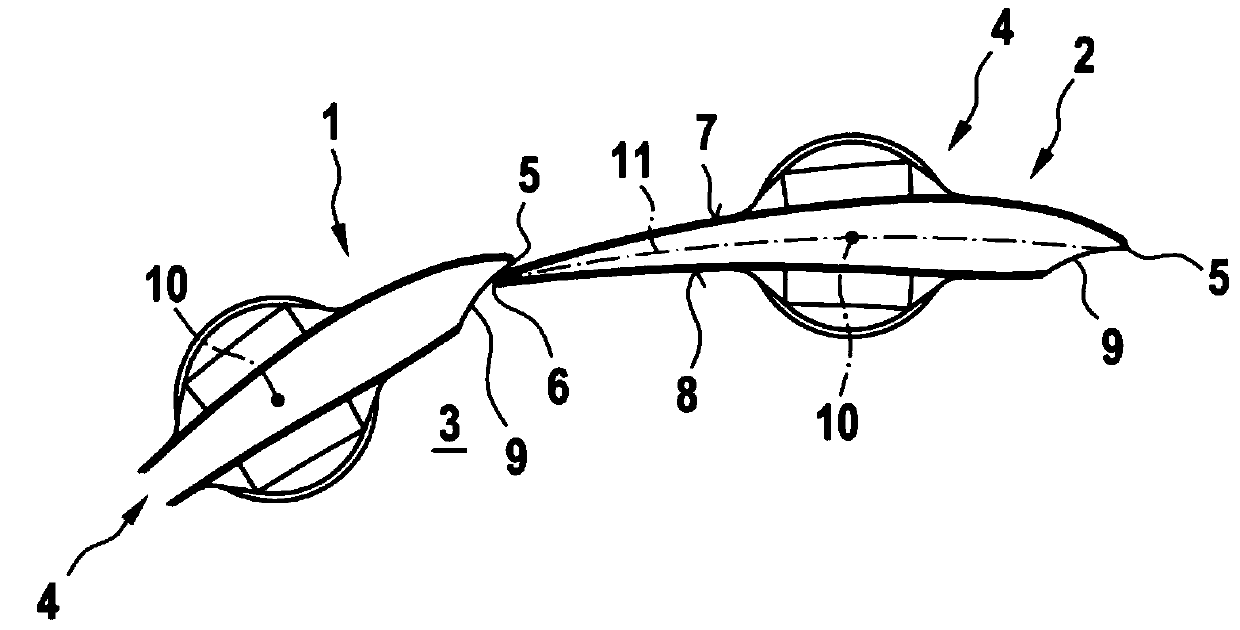

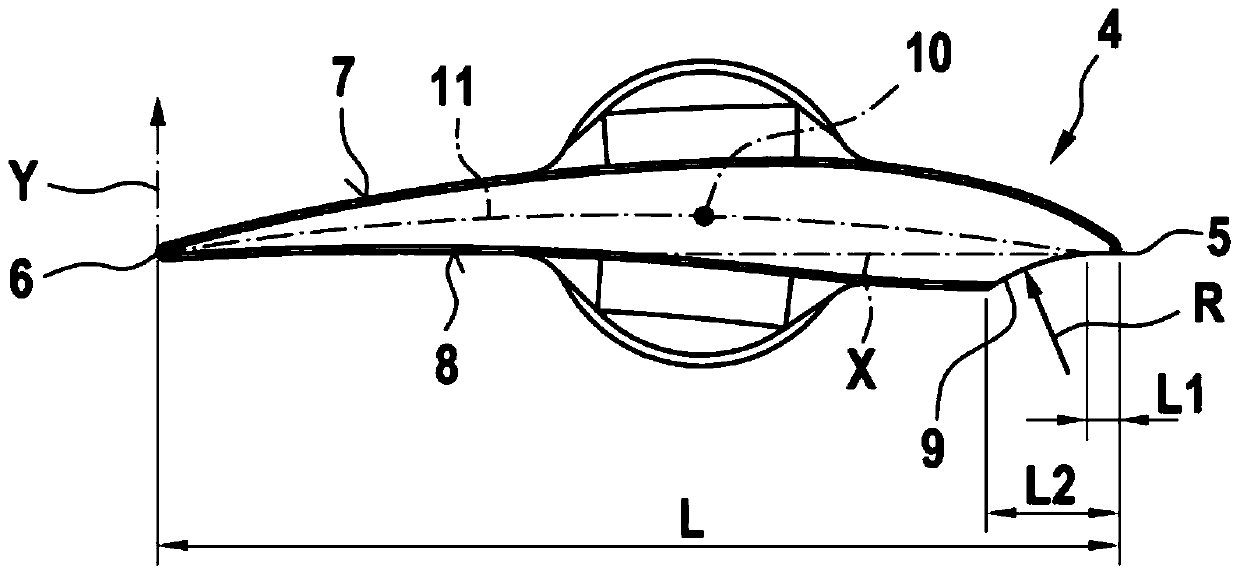

[0021] corresponds to figure 1 , the supercharger device 1 according to the invention, for example in a motor vehicle, can be in the form of an exhaust-gas turbocharger, which supercharger device 1 has a variable geometry turbine 2, has a blade bearing ring 3, and has a rotatable The guide vanes 4 are installed in the vane bearing ring 3. The guide vanes 4 are additionally shown in figure 2 , again shown in image 3 in the detail drawing. With regard to the guide vane 4 it can be seen that it has a top side 7 extending in a convex form from the profile nose 5 to the profile end 6 . Concave groove 9 (see especially also figure 2 with image 3 ) is arranged on the underside 8 of the guide vane 4 at the profile nose 6 . Here too, the bottom side 8 extends in concave form from the concave groove 9 to the profile end 6 , wherein the radius of curvature of the bottom side 8 is greater than the radius of curvature R of the groove 9 .

[0022] Here, the radius of curvature R ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com