Cosmetic containing active peptide

A technology of active peptides and cosmetics, applied in the field of cosmetics containing active peptides, can solve problems such as skin allergic reactions and induce other diseases, and achieve the effects of good water solubility, improved skin elasticity, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

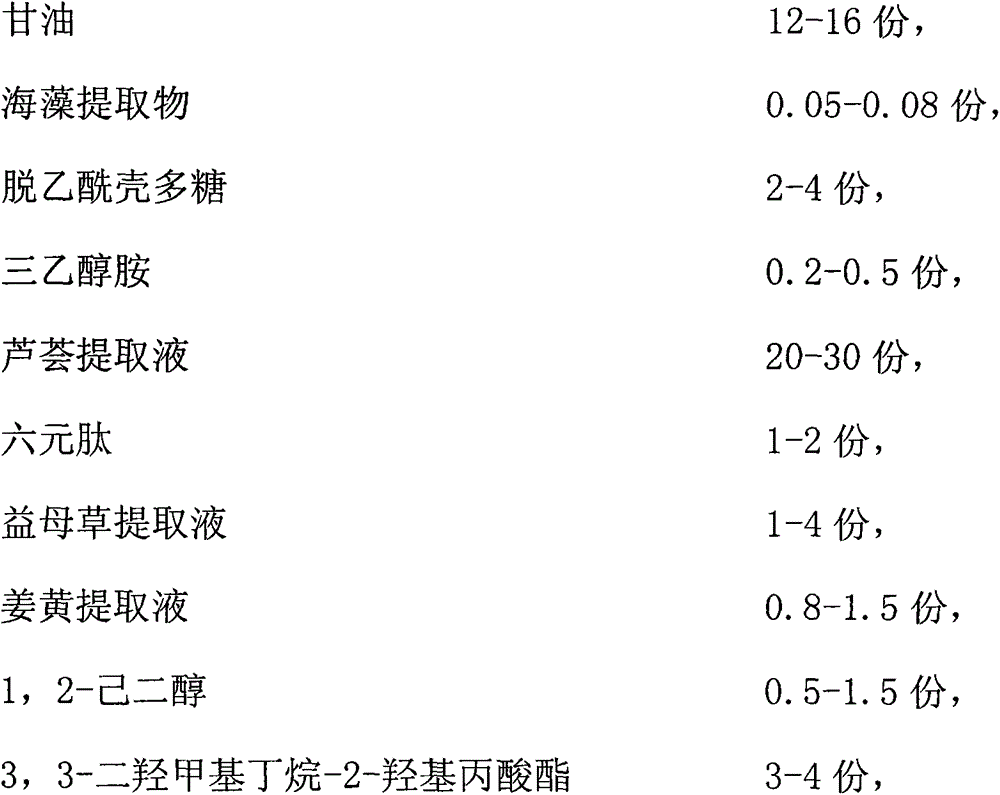

[0021] A kind of cosmetic containing active peptide, its raw material comprises by weight:

[0022]

[0023] The active peptide is extracted from silk, and the process of extracting active peptide from silk is as follows: weigh 2 parts of silk by weight, add 15 parts of water and 0.5 part of sodium sulfite, stir evenly, heat to 80°C and mix for 8 hours, then cool to 55°C , adjust the pH value to 7.9, add 0.01 part of 30,000 U / g alkaline protease, and stir the enzymolysis at constant temperature for 6 hours. During the enzymolysis process, use sodium hydroxide to keep the pH value of the system stable, raise the temperature to 90°C, and inactivate the enzyme at constant temperature for 10 minutes. Filter the supernatant, add 0.06 parts of powdered activated carbon, stir at 60°C for 2 hours, filter to remove the activated carbon, use membrane separation technology to desalt and concentrate, dry to obtain the active peptide.

[0024] A kind of cosmetic containing active peptid...

Embodiment 3

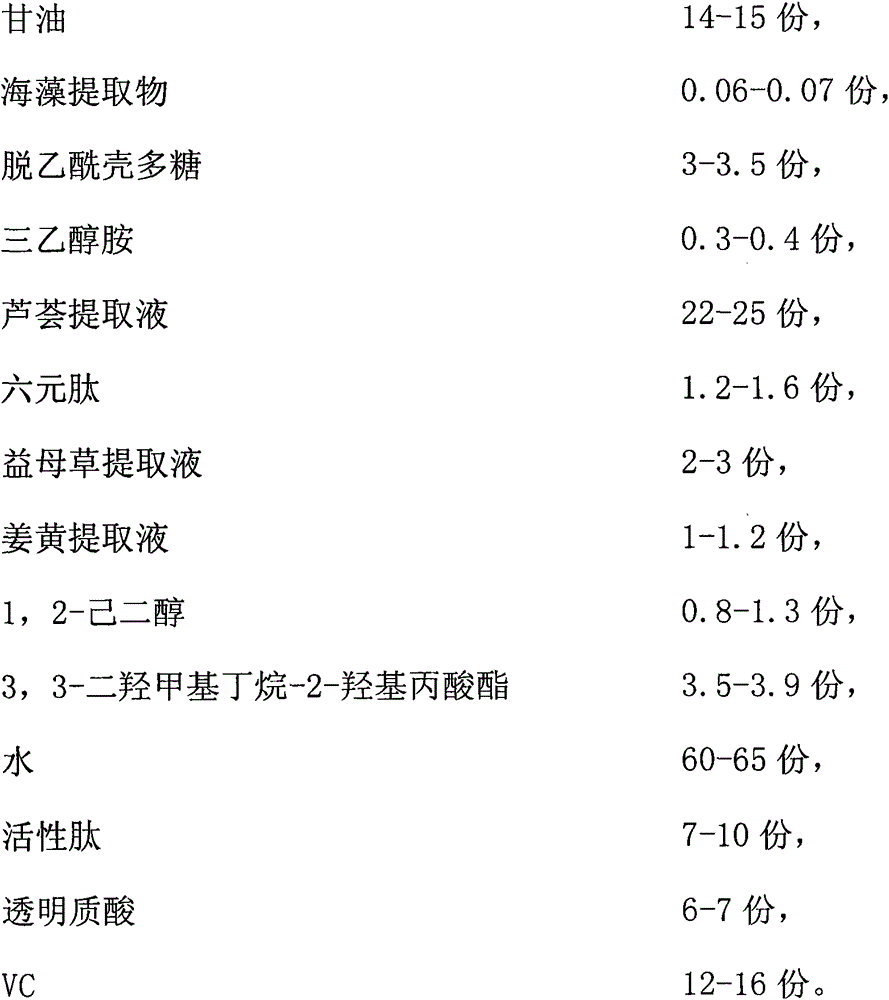

[0028] A kind of cosmetic containing active peptide, its raw material comprises by weight:

[0029]

[0030] The active peptide is extracted from silk and sheep placenta.

[0031] The process for extracting active peptides from silk is as follows: weigh 2 parts of silk by weight, add 16 parts of water and 0.45 parts of sodium sulfite, stir evenly, heat to 95°C and mix for 6 hours, cool down to 680°C, adjust the pH value to 7.8, add 0.05 parts of 30,000 U / g alkaline protease, stirred at constant temperature for 5 hours, kept the pH value of the system stable with sodium hydroxide during the process of enzymolysis, raised the temperature to 93°C, inactivated the enzyme at constant temperature for 7 minutes, filtered the supernatant, added 0.08 Parts of powdered activated carbon, stirred at 57°C for 2.5h, filtered to remove the activated carbon, desalted and concentrated by membrane separation technology, dried to obtain the active peptide.

[0032] The preparation process of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com