Method for simulating fracture failure of air-inlet grille by adopting EFGM in car collision

An air intake grille and vehicle collision technology, which is applied in the field of automobile collision modeling, can solve problems such as insufficient strength evaluation accuracy, and achieve the effect of ensuring random characteristics, ensuring calculation accuracy, and ensuring calculation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Using EFGM to simulate the fracture failure method of the air intake grille in a car collision, the specific steps are as follows:

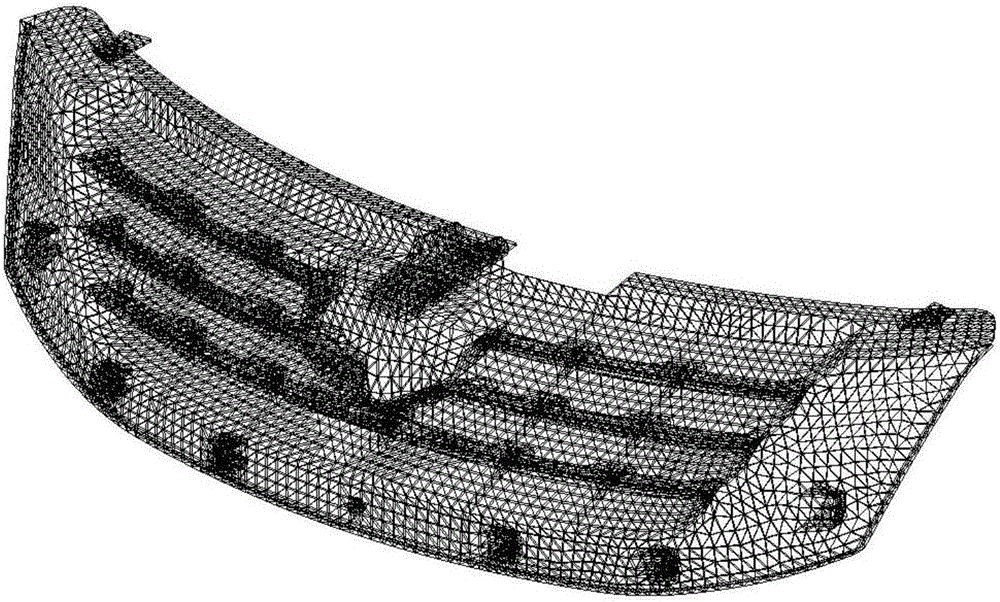

[0028] S1. The air intake grille adopts 4-node tetrahedron as a discrete element, and the background grid is preset;

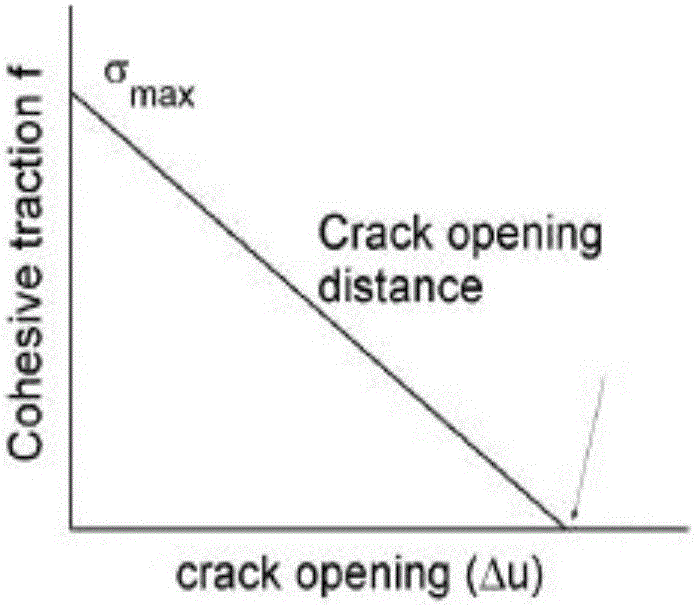

[0029] S2. Endow the air intake grille with multi-linear elasto-plastic follow-up strengthening constitutive, and use the cohesive element fracture method to determine how much force is applied between the discrete points, and the detachment occurs, that is, the effect of fracture is expressed;

[0030] S3. Use the calibration test for the constitutive parameters of the intake grille of the corresponding model and the parameters of the EFGM algorithm itself: if the simulation results are consistent with the calibration test, proceed to step S4; if the simulation results are inconsistent with the calibration test, adjust the constitutive parameters of the intake grille parameters and the parameters of the EFGM algorithm its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com