Modularization furniture jointing fixing piece

A technology of modularization and fixing parts, which is applied in the direction of furniture connection, connection components, thin plate connection, etc., and can solve problems such as inconvenient transportation, loose connection of furniture modules, and large screw force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

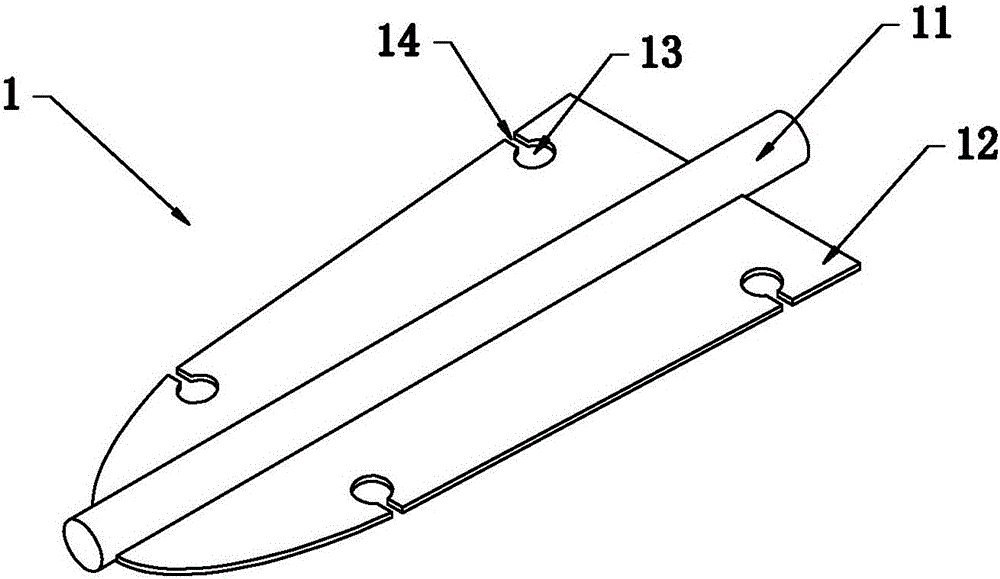

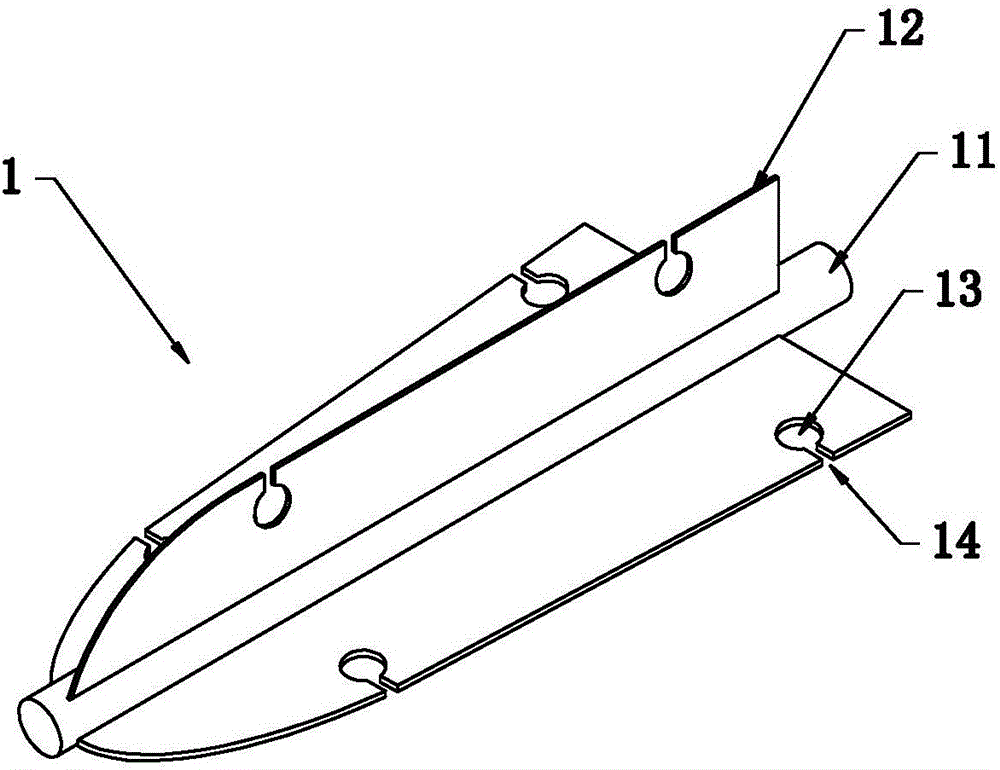

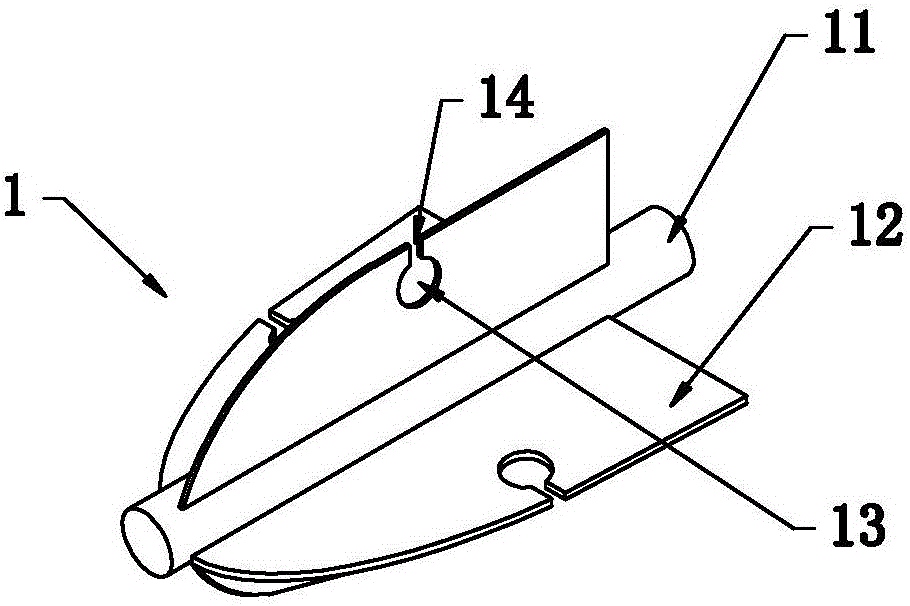

[0031] Such as Figure 1 to Figure 6 Compared with the prior art, the shown modular furniture splicing fixture mainly includes a plug board 1 and a lock catch 2 cooperating with the plug board 1 . Wherein, the flashboard 1 has a main body 11, and at least two ribs 12 extend from the main body 11 in a direction perpendicular to its length, and at least one locking hole 13 is opened at the edge of each rib 12, Each lock hole 13 is provided with a lock opening 14 . The buckle 2 includes a cap 21 for twisting the buckle 2 and a catch 22 for preventing the buckle 2 from falling off the board 1 . Locking teeth 23 are provided between the cap 21 and the catch 22 . When the plate 1 is mated with the buckle 2, the rib 12 is inserted between the cap body 21 and the blocking piece 22, and the lock tooth 23 enters the lock hole 13 only through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com