Novel sealing bolt for machine tool protective cover and assembly structure of sealing bolt

A technology for sealing bolts and assembling structures, applied in nuts, connecting components, mechanical equipment, etc., can solve the problems of splashing coolant, misalignment of connecting holes, and large amount of coolant, and achieve the effect of solving the problem of leakage and penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

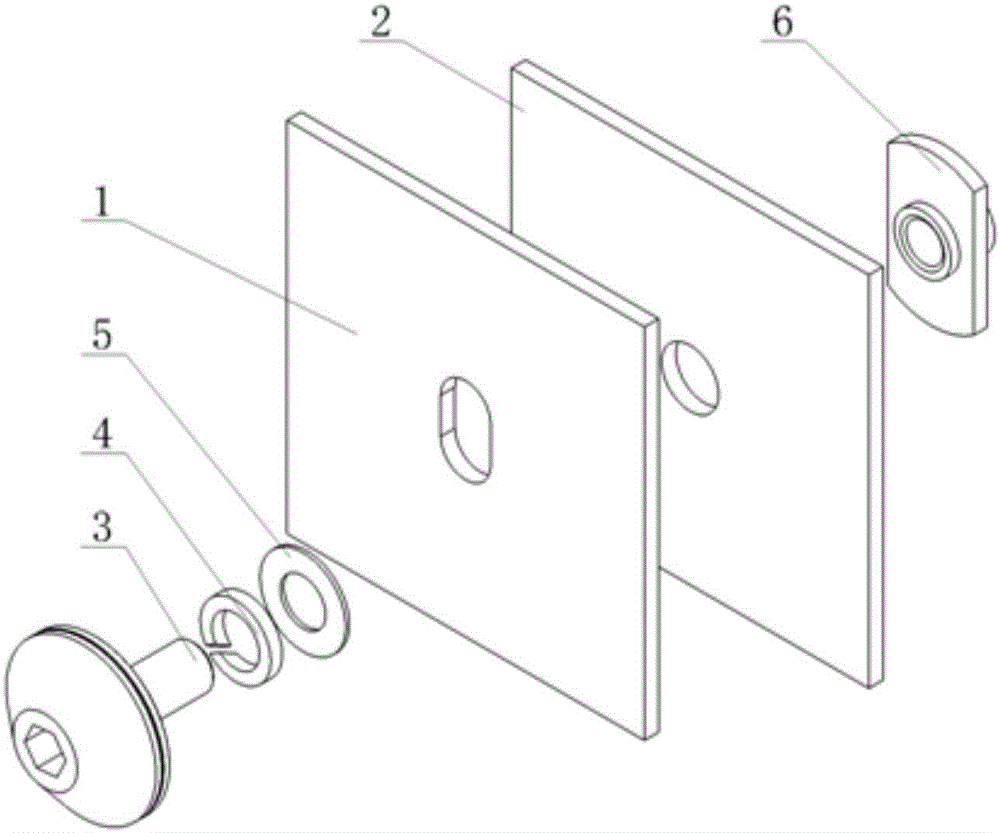

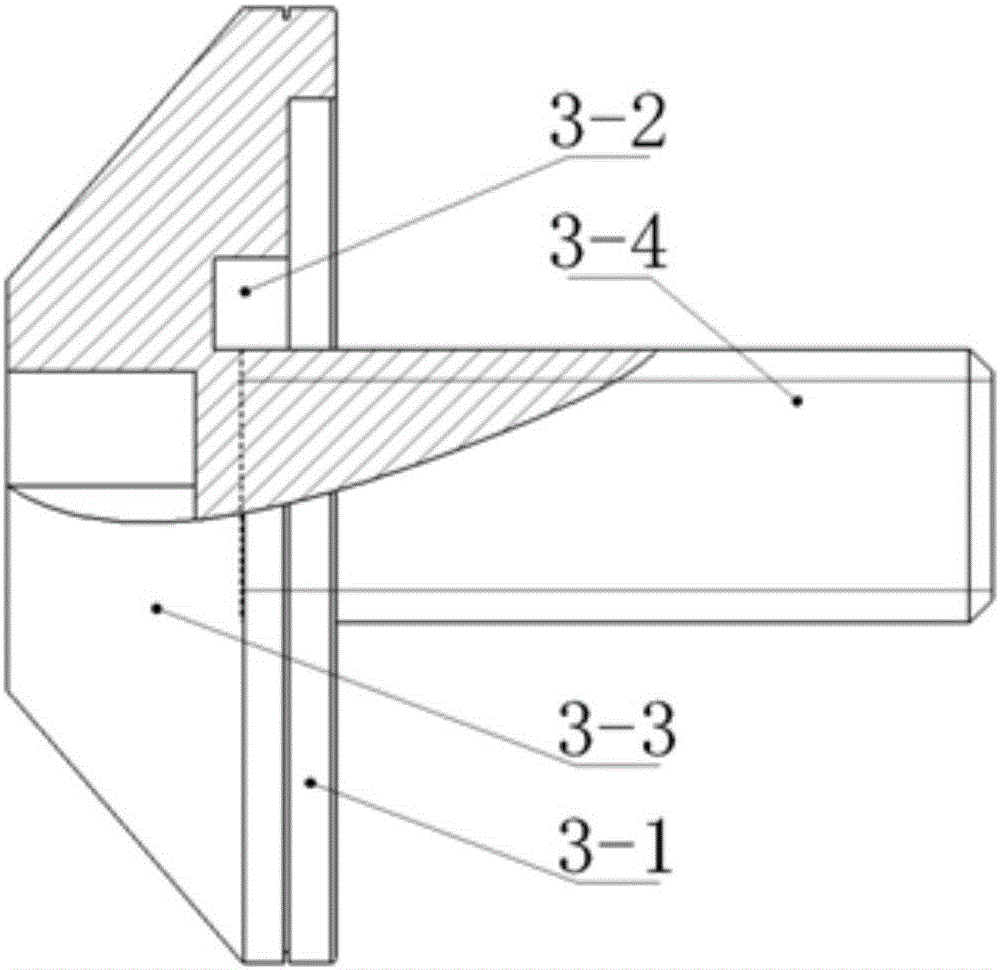

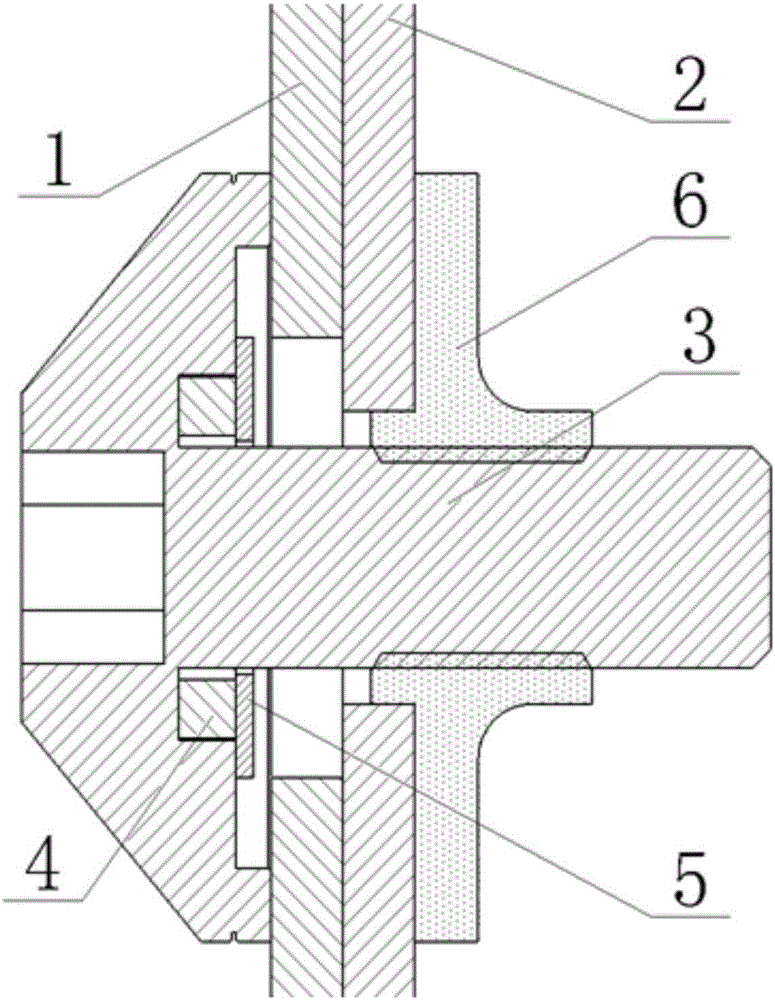

[0011] Below in conjunction with all accompanying drawings the present invention will be further described, and preferred embodiment of the present invention is: see appended figure 1 to attach Figure 4 , the machine tool protective cover described in the present embodiment uses novel sealing bolt and assembly structure thereof, and it comprises sheet metal part A, sheet metal part B, sealing bolt 3, elastic washer 4, flat washer 5, welding nut 6, wherein, A through hole is provided at the center of the sheet metal part B, a welding nut 6 matching the through hole is provided on one side of the sheet metal part B, a sheet metal part A is provided on the other side of the sheet metal part B, and a The waist-shaped hole connected with the through hole; the sealing bolt 3 is composed of a bolt rod 3-4 and a bolt head 3-3, the bolt head 3-3 is conical, and the larger end of the bolt head 3-3 is provided with a spring washer Slot 3-2, one end of the bolt rod 3-4 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com