Rotary excavating pile machine hole bottom hydraulic high-frequency in-the-hole rock breaking drill of rotating joint inner and outer drill rod rotation stopping type

A rotary joint and rotary pile driver technology, which is applied in the direction of rotary drilling, drilling equipment and methods, and driving devices for drilling in boreholes, etc. It can solve the problems of large vibration force of the hammer body and large volume of the rotary joint of the oil pipe, etc. , to achieve the effect of large impact force, improved service life and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

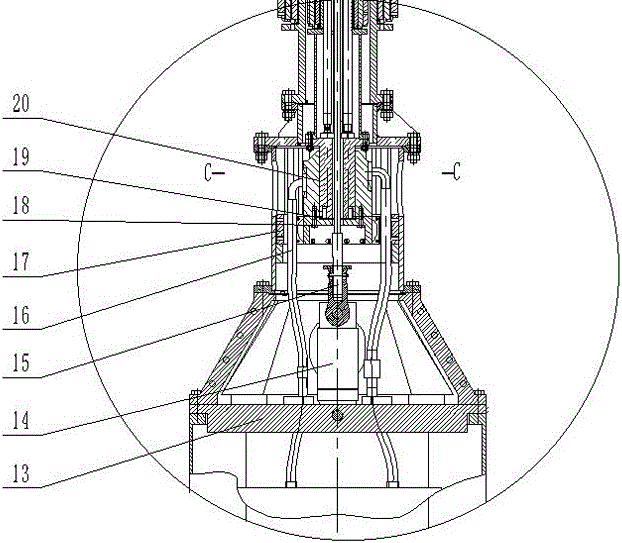

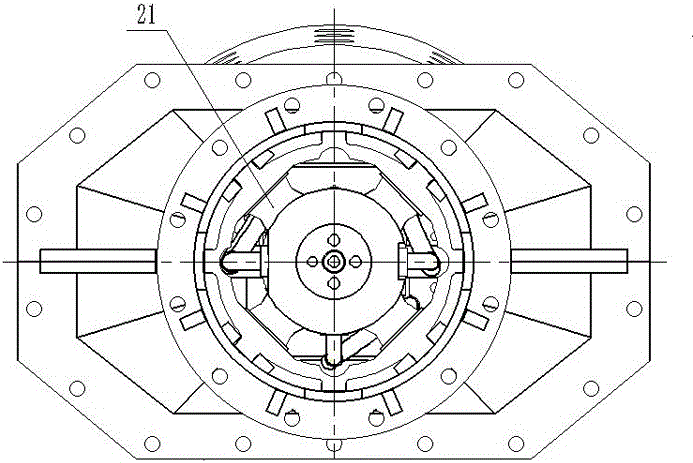

[0012] Such as figure 1 , 2 , 3, the drill rod of the hydraulic high-frequency down-the-hole rock-breaking drill at the bottom of the rotary pile machine of the present invention includes an inner telescopic drill rod 6 and an outer telescopic drill rod 7 that is sleeved on the outside of the inner telescopic drill rod 6; the inner telescopic drill rod 6 The upper end of the rotary joint 20 is fixed under the follower frame 5 of the rotary pile machine, the upper end of the rotary joint 20 is connected to the lower end of the inner telescopic drill rod 6, the lower end of the rotary joint 20 is fixed with a rotating body seat 18, and the lower end surface of the central axis of the rotary joint 20 The wear-resistant plate 19 is in contact with the rotating body seat 18, and the rotating body seat 18 is connected to the shock absorbing seat 17 through the shock absorbing rubber 21, and the shock absorbing seat 17 is fixed in the sliding cylinder 9; the upper end of the sliding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com