A Synchronous Sliding Construction Technology of Double-span Network Frame with Center Column

A technology of synchronous slippage and construction technology, applied in construction, building structure, construction material processing and other directions, can solve the problems of difficult to control the deflection of the large-span grid, difficult to guarantee the installation period, and high safety risk factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

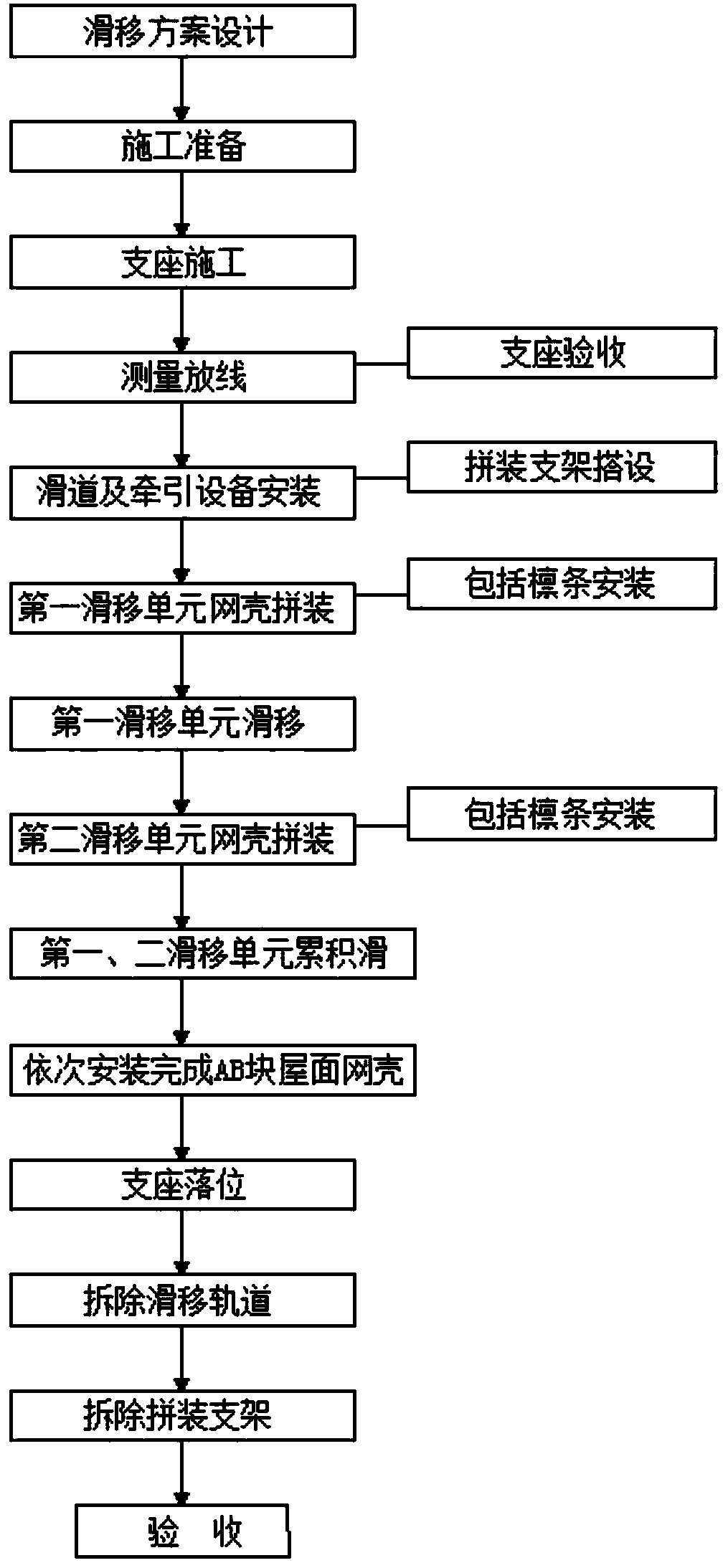

[0036] This embodiment provides a double-span network frame with a central column synchronous sliding construction process, such as figure 1 shown, including the following steps:

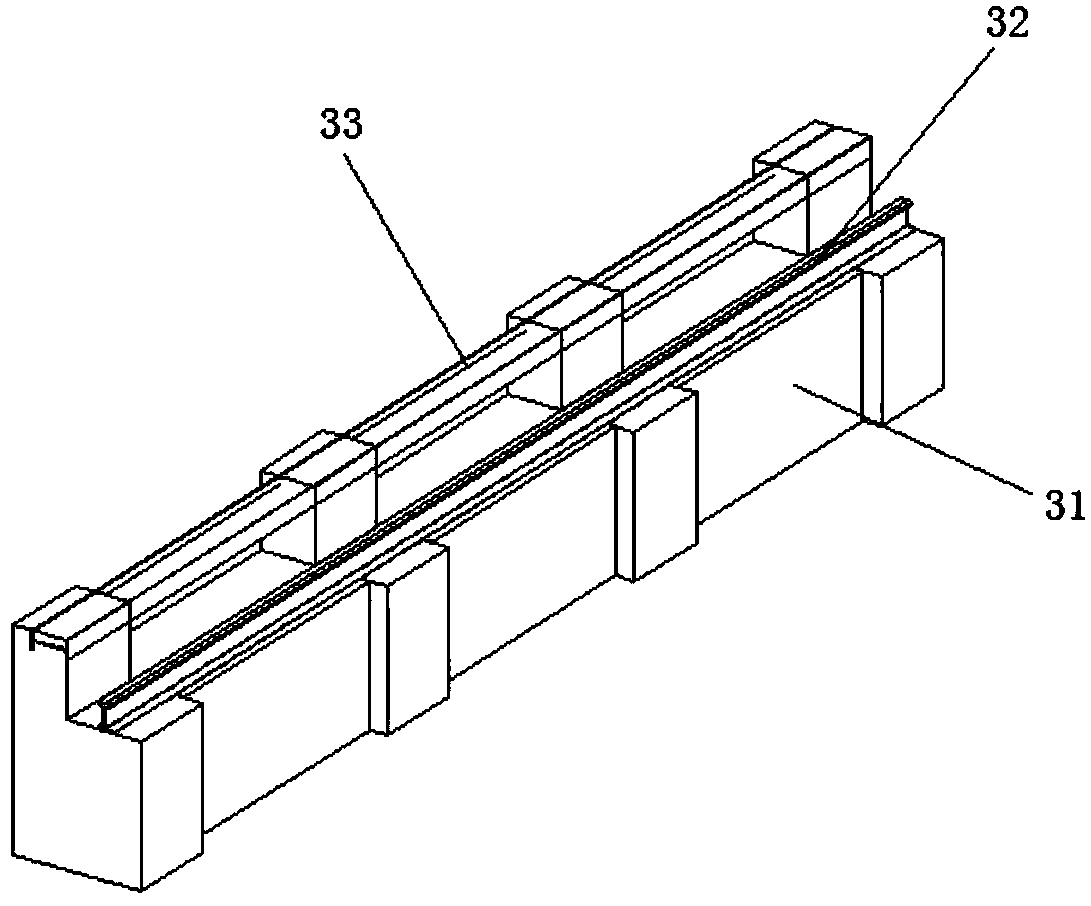

[0037] (1) According to the design requirements of the network frame, the double-span network frame is divided into AB axis grid shell and CD axis grid shell. The double-span grid frame is equipped with a horizontal track 32 on the concrete foundation 31 at the support of the A axis and the D axis, and the bearing network For the vertical load of the shell structure, the lateral rail 33 is set at the elevation of the foundation center of the concrete lateral support, and the lateral rail 33 adopts H-shaped steel to bear the lateral horizontal thrust of the reticulated shell structure. The track adopts 43Kg / m heavy rail, and the 43Kg / m heavy rail is installed on the vertical track beam, and welded to the vertical track beam by intermittent welding, the length of the intermittent welding seam is >100m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com