A method for overall hoisting of super-large converter shell

A converter shell and overall hoisting technology, which is applied in the manufacture of converters, transportation and packaging, load hanging components, etc., can solve the inconvenience of hoisting methods for super-large converter shells, the great impact on the steelmaking construction period, and the existence of safety risks and other issues, to achieve the effect of safe and reliable hoisting engineering quality, significant economic effects, and reduced engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

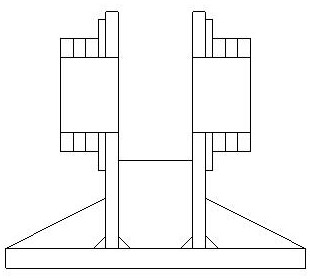

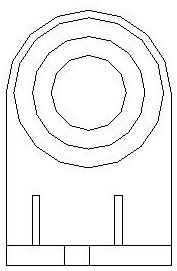

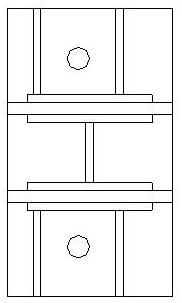

[0038] The overall hoisting method of the super-large converter shell of the present invention comprises the following steps:

[0039] a. The overall hoisting scheme of the converter shell is determined.

[0040] (1) Carry out a comprehensive evaluation of the two known converter installation methods of "trolley jacking method" and "converter sliding method", and select the overall hoisting method of the converter shell that is suitable for the site environment and construction period.

[0041] (2) Hoisting load calculation: measure and calculate the installation elevation of the metallurgical bridge crane track, the center elevation of the balance beam shaft sleeve of the bridge crane and the maximum lifting elevation at the bottom of the converter shell, select a suitable heavy metallurgical bridge crane, and confirm that the heavy metallurgical bridge crane The lifting capacity of the crane is greater than the weight of the converter shell, which can meet the overall hoisti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com