Adjustable compaction machine

A tamping machine, adjustable technology, applied in the direction of mechanical equipment, soil protection, transmission devices, etc., can solve the problems of fixed impact distance of rammer, inability to adjust freely, difficult tamping work, etc., to reduce vibration frequency and save space , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

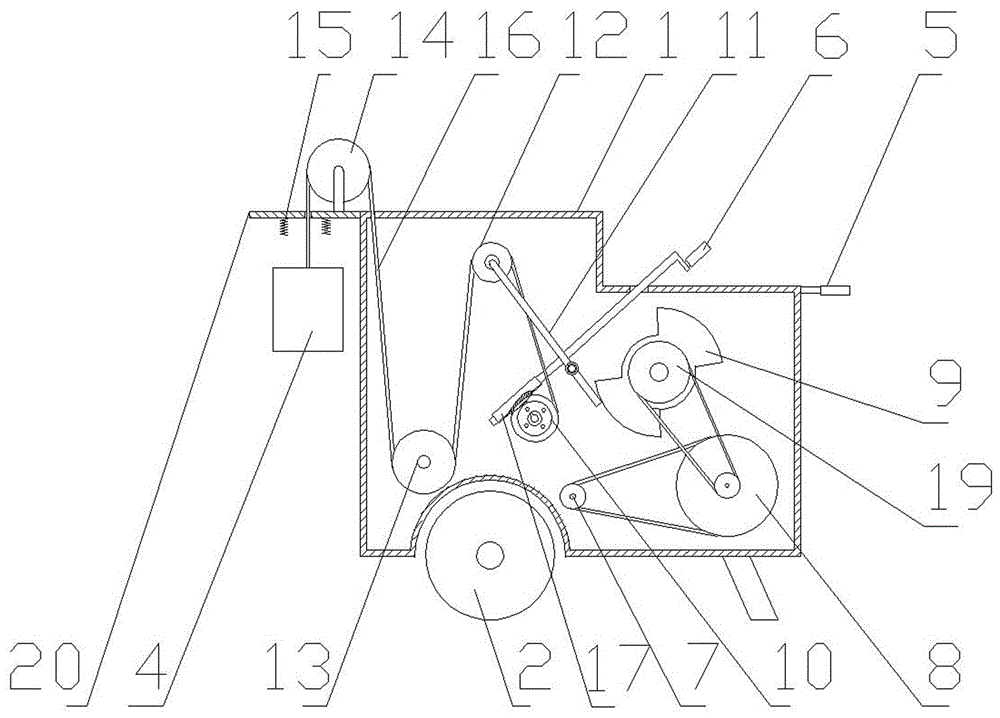

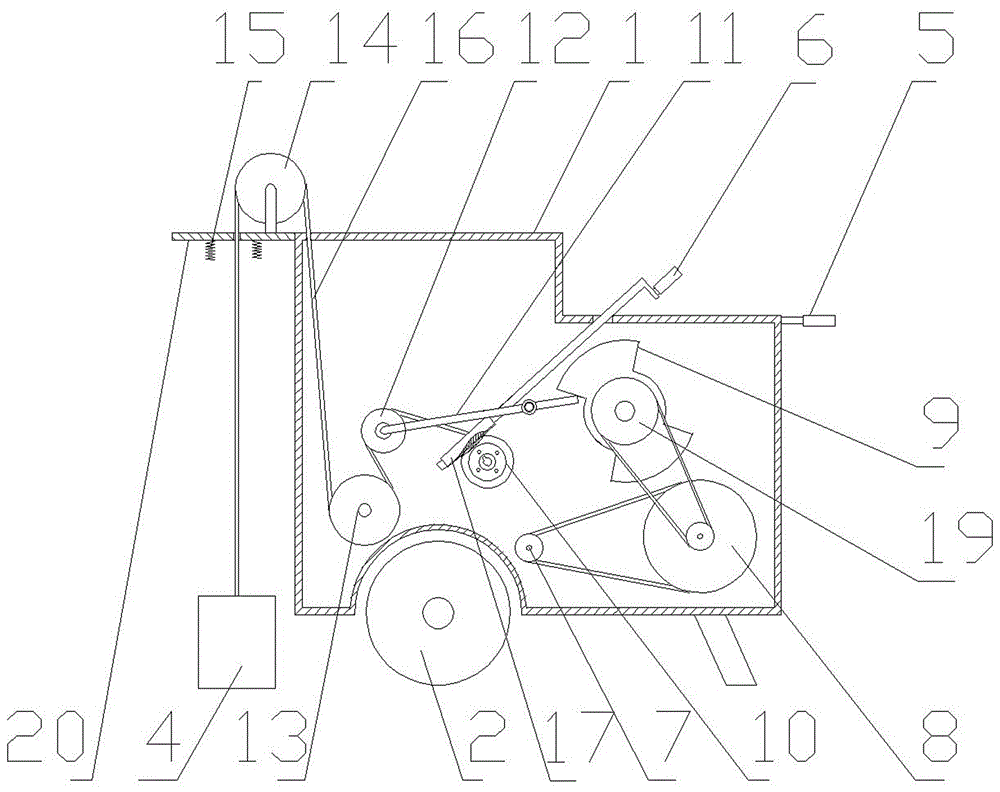

[0031] The present invention will be further described below in conjunction with accompanying drawing.

[0032] like Figure 1-4 As shown, the present invention includes a frame 1, a rammer 4 arranged at the front end of the frame 1, a transmission device that drives the rammer 4 to perform periodic lifting movements under the action of gravity, and is arranged inside the frame 1. The control device used to control the work of the transmission device and the adjustment device fixedly arranged on the frame 1 and used to adjust the impact depth of the rammer 4; the lower end of the frame 1 is provided with wheels 2, and the frame 1. A handle 5 is provided at the rear end; the rammer 4 is a flat-headed rammer.

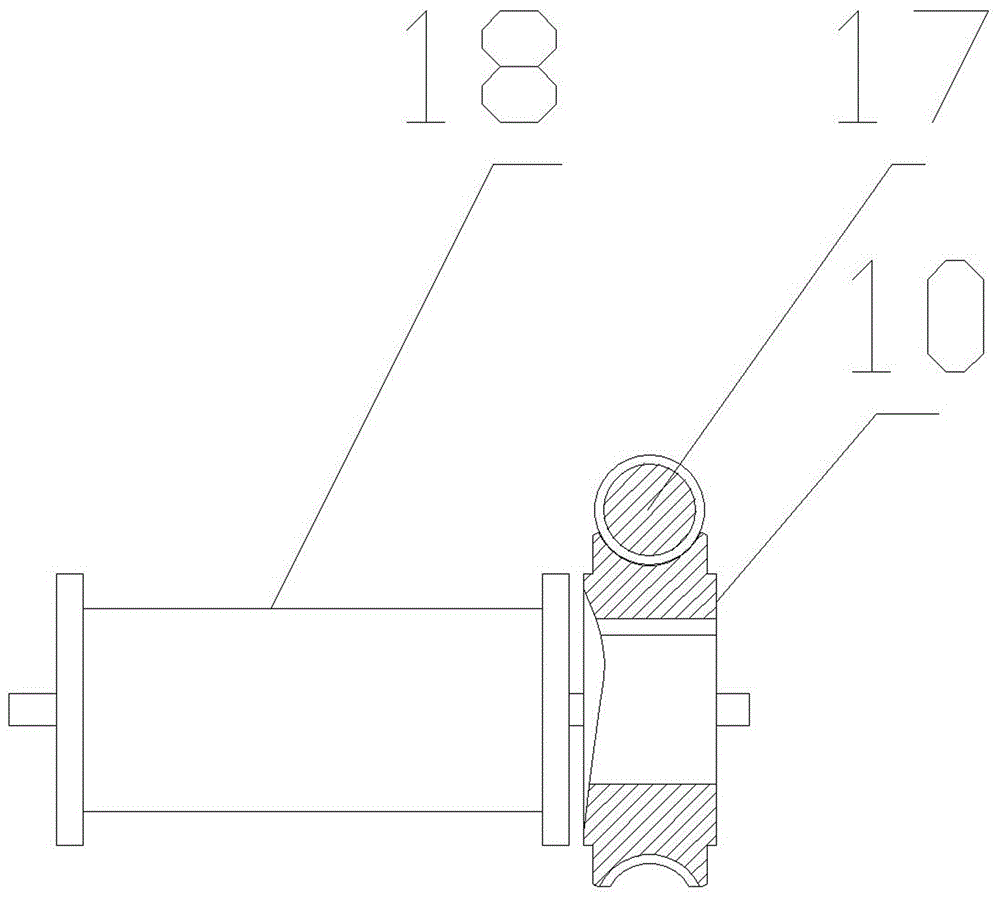

[0033] The adjustment device includes a telescopic table 20 arranged on the frame 1 and adjustable front and rear along the frame 1, a rope winding roller 18 arranged on the frame 1, and coaxially arranged on the rope winding roller 18. The turbine 10 at one end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com