Car lift capable of being braked

A lift and lifting column technology, applied in the field of brakeable lifts, can solve problems such as safety accidents, and achieve the effects of preventing sudden falls, high safety performance, and high risk prevention functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

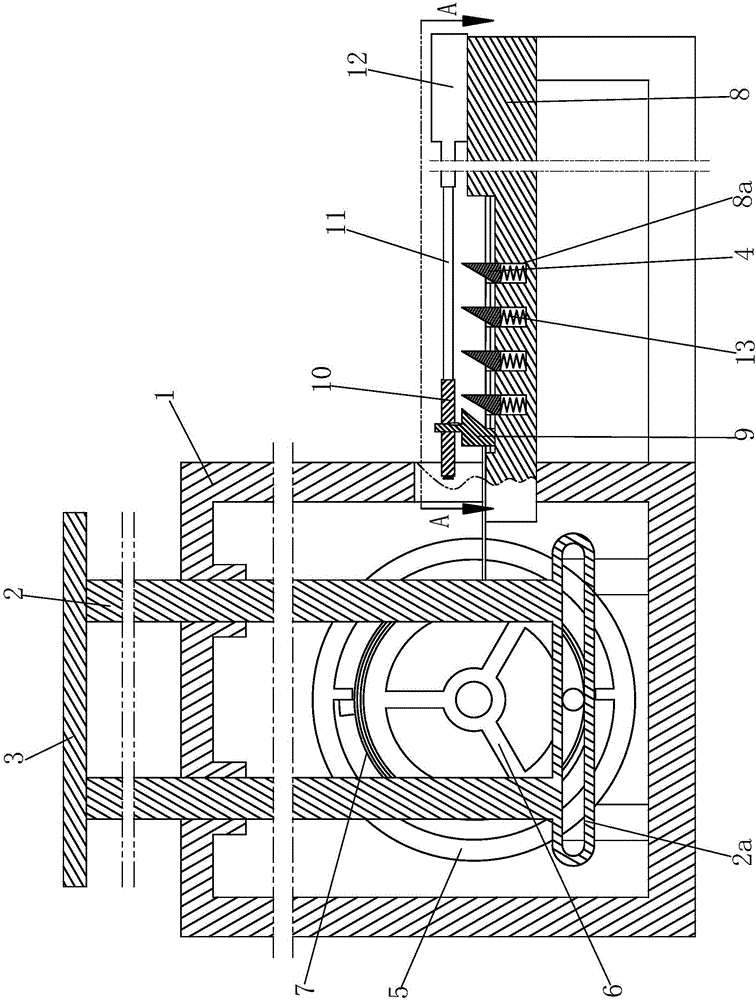

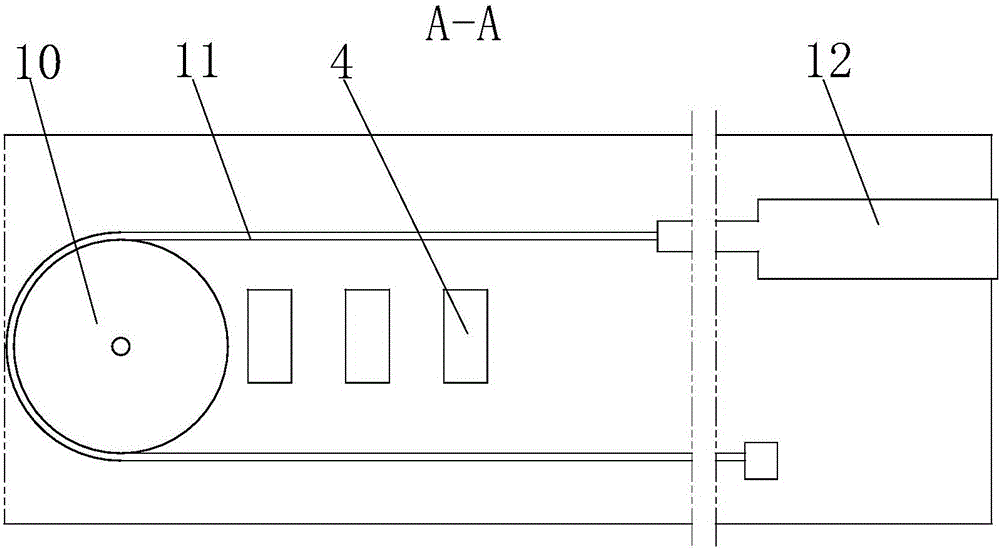

[0017] Such as Figure 1 to Figure 2 As shown, a brakeable lift includes a bottom box 1 on which a lifting column 2 is slidably installed in the longitudinal direction, and a lifting platform 3 is fixedly connected to the upper end of the lifting column 2 .

[0018] The lower end of the lifting column 2 is provided with a horizontal waist-shaped groove 2a, and a box seat 5 is installed inside the bottom box 1, and the center of the box seat 5 is movably equipped with a circular runner 6. The edge is welded with a cylinder that is slidably installed in the waist-shaped groove 2a, and the outer surface of the circular wheel 6 is wound with a cable 7 .

[0019] A horizontal sliding frame 8 is installed on the right side of the bottom box 1, and the other end of the cable 7 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com