Combined type pneumatic flexible finger

A flexible finger, combined technology, applied in the field of combined pneumatic flexible fingers, can solve the problems of lack of diversity, flexibility, fixation, single action form and control method, and achieve the effect of good application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

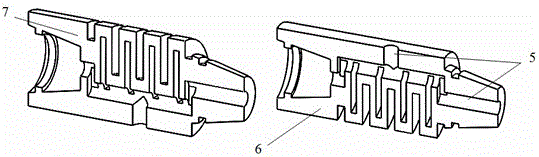

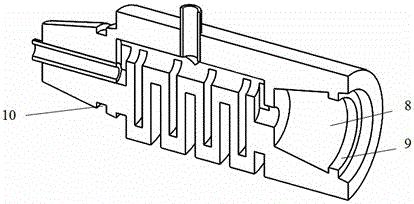

[0018] The combined pneumatic flexible finger of the present invention is mainly composed of silicone finger block A 6, silicone finger block B 7, branch trachea 11, connecting trachea 12, silicone finger segment 16, fingertip 15, cable tie 14, and blue butyl rubber 19.

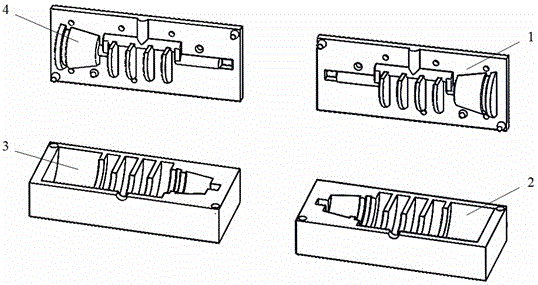

[0019] First, use a 3D printer or a mechanical processing method to manufacture upper mold A 1 , lower mold A 2 , upper mold B 3 , and lower mold B 4 . Pour the liquid silicone into the mold in a vacuum box to exclude air from the liquid silicone. After the silicone finger block in the mold is solidified and formed, take it out, remove and clean the excess parts such as gates and risers on the silicone finger block.

[0020] Put the branch trachea 11 and the connecting trachea 12 into the air hole 5 of the silicone finger block and bond them with liquid silicone, apply liquid silicone evenly on the joint surfaces of the silicone finger block A 6 and the silicone finger block B 7, close them and stick them tog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com