False pressure head and operating method thereof

A working method and false pressure technology, applied in the direction of electrical components, printed circuit manufacturing, electrical components, etc., can solve the problems of high procurement cost and low production efficiency, achieve the effect of reducing material throwing rate, reducing procurement cost, and ensuring handover accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

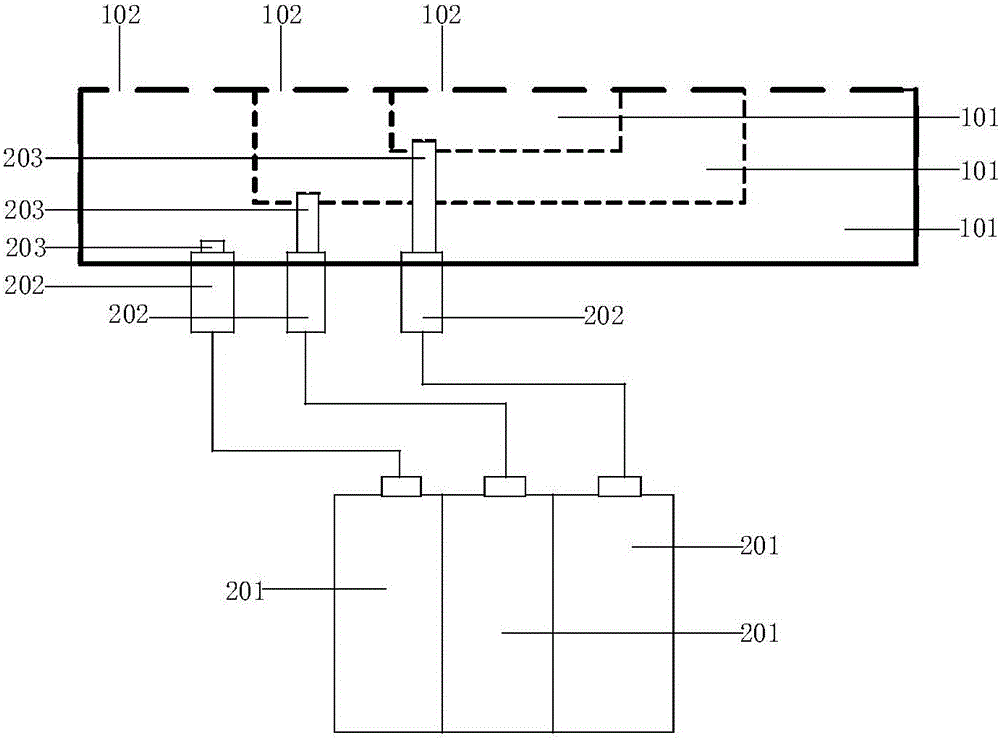

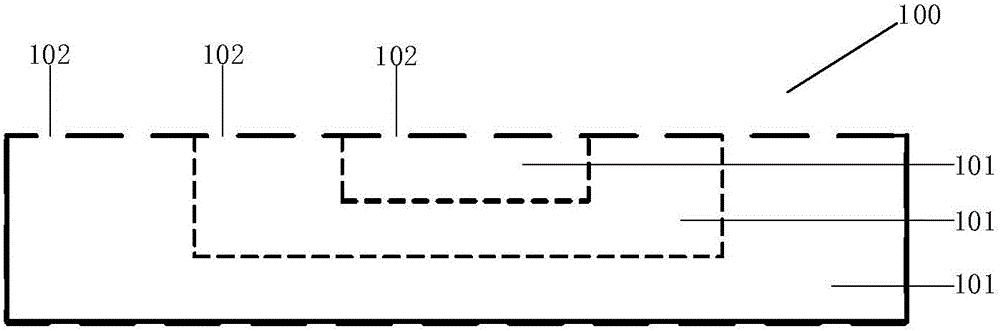

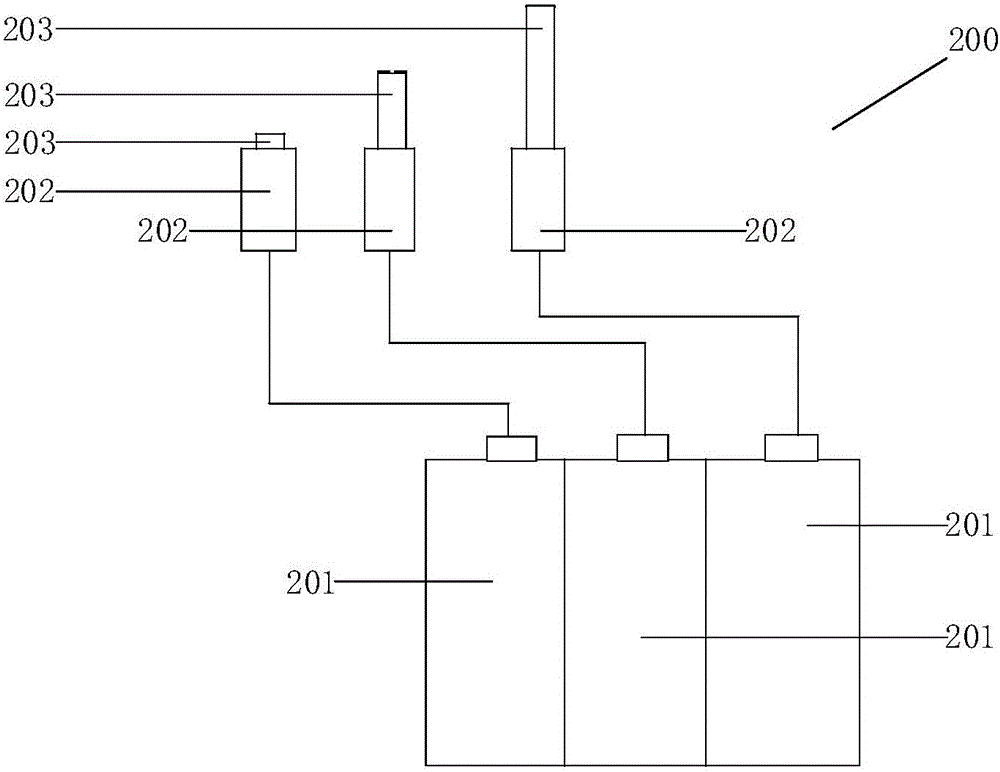

[0042] figure 1 It is a schematic structural diagram of a dummy indenter provided in Embodiment 1 of the present invention, figure 2 for figure 1 Schematic diagram of the structure of the adsorption unit shown, image 3 for figure 1 Schematic diagram of the structure of the control unit shown. Such as Figure 1-3 As shown, the dummy pressure head includes an adsorption unit 100 and a control unit, and the adsorption unit includes at least two vacuum adsorption structures, and the vacuum adsorption structure includes an air path 101 and at least one air hole 102, and the air path 101 is connected to the air hole 102. The air holes 102 are in communication. see Figure 1-2 , the number of vacuum adsorption structures is 3, and the object to be adsorbed is COF (Chip On Flex or Chip On Film, chip-on-film) or FPC (FlexiblePrinted Circuit, flexible circuit board).

[0043] In this embodiment, the control unit separately controls the formation of the vacuum environment of eac...

Embodiment 2

[0048] Figure 4 It is a flowchart of a working method of a dummy indenter provided by Embodiment 2 of the present invention. Such as Figure 4 As shown, the dummy pressure head includes an adsorption unit and a control unit, the adsorption unit includes at least two vacuum adsorption structures, the vacuum adsorption structures include an air path and at least one air hole, and the air path communicates with the air hole. The working method of described dummy indenter comprises:

[0049] Step 1001, the control unit separately controls the formation of the vacuum environment of each of the vacuum adsorption structures according to the size of the target to be adsorbed.

[0050] Step 1002, the adsorption unit performs an adsorption action on the target to be adsorbed under the control of the control unit.

[0051] see Figure 1-3 , the number of vacuum adsorption structures is 3, and the object to be adsorbed is COF (Chip On Flex or Chip On Film, chip-on-film) or FPC (Flexi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com