Boiling-type water boiler

A boiling type, water boiler technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of inability to provide boiled water for drinking, inability to continuously supply boiling water, and inability to achieve complete sterilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

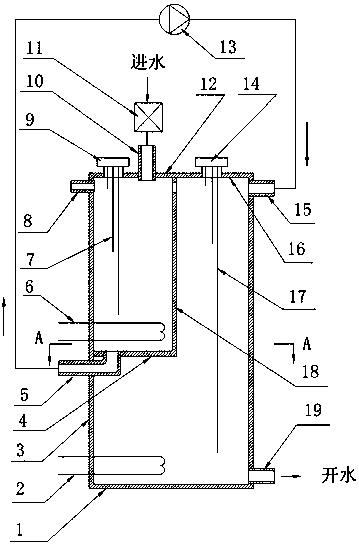

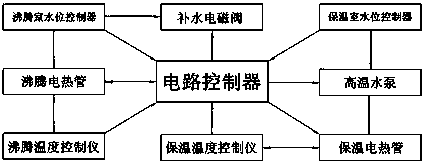

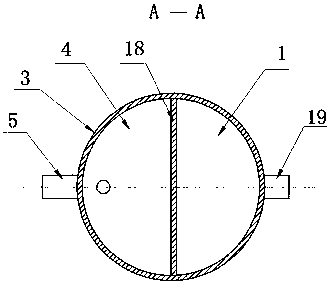

[0020] As shown in the attached figure, a boiling water boiler includes a circuit controller, a bottom plate 1, an electric heating tube for heat preservation 2, a cylinder body 3, a transverse partition 4, a water outlet pipe 5 in the boiling chamber, an electric heating tube 6, and a water level electrode 7 in the boiling chamber , overflow pipe 8, boiling chamber electrode head 9, water replenishment pipe 10, water replenishment solenoid valve 11, through hole 12, hot water pump 13, heat preservation chamber electrode head 14, heat preservation chamber inlet pipe 15, cylinder upper cover 16, heat preservation chamber water level Electrode 17, vertical partition 18, boiling water outlet pipe 19, boiling chamber 20, heat preservation chamber 21.

[0021]Described boiling water boiler is formed airtight container by base plate 1, cylinder body 3 and cylinder body upper cover 16, and the semicircular diaphragm 4 that takes cylinder body 3 inner radius as radius is arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com