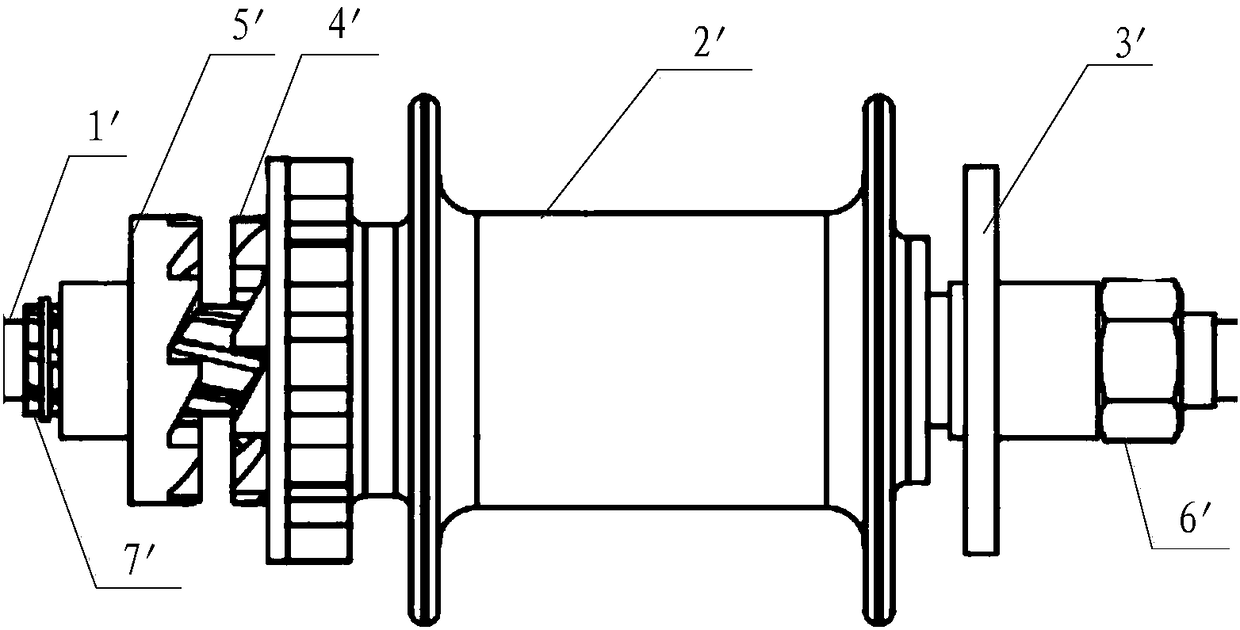

An automatic jaw clutch

A jaw clutch and clutch technology, applied in the field of clutches, can solve problems such as complex spindle fixing methods, high friction of power ratchets, and increased cost of use, and achieve the effects of simple structure, reduced friction, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

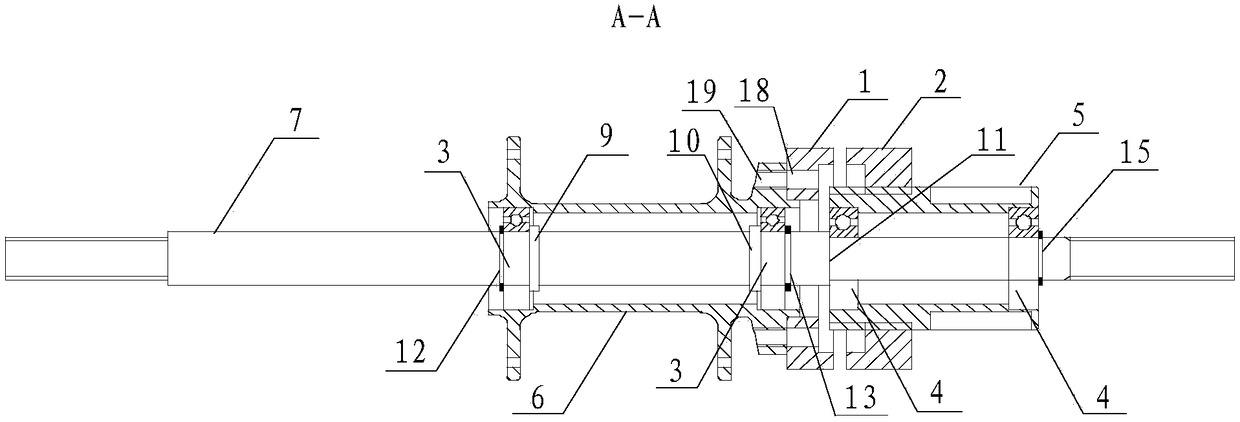

[0029] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

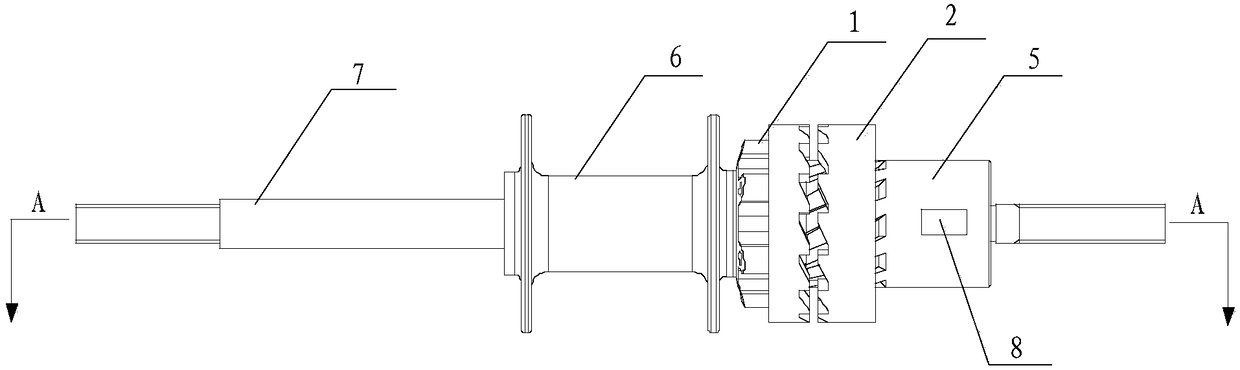

[0030] Such as Figure 2-3 Shown, a kind of automatic jaw clutch, it comprises first half clutch 1, second half clutch 2, first bearing 3, second bearing 4, spline sleeve 5, hub 6 and axle 7, described axle 7 is an elongated cylindrical shaft; the hub 6 is sleeved on the hub 7, and the two ends of the hub 6 are rotationally connected to the hub 7 through the first bearing 3; the first One end of the half-clutch 1 is provided with passive teeth, and the other end is fixedly connected with the hub 6; the spline sleeve 5 is sleeved on the wheel shaft 7, and the two ends of the spline sleeve 5 respectively pass through the The second bearing 4 is rotatably connected with the wheel shaft 7, the spline sleeve 5 is close ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com