Rectangular precise gap adjusting bearing

A gap adjustment and rectangular technology, which is applied in the field of rectangular precision gap adjustment bearings, can solve the problems of increased processing difficulty and long processing time, and achieve the effect of reducing processing difficulty, reducing design work, and reducing design difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

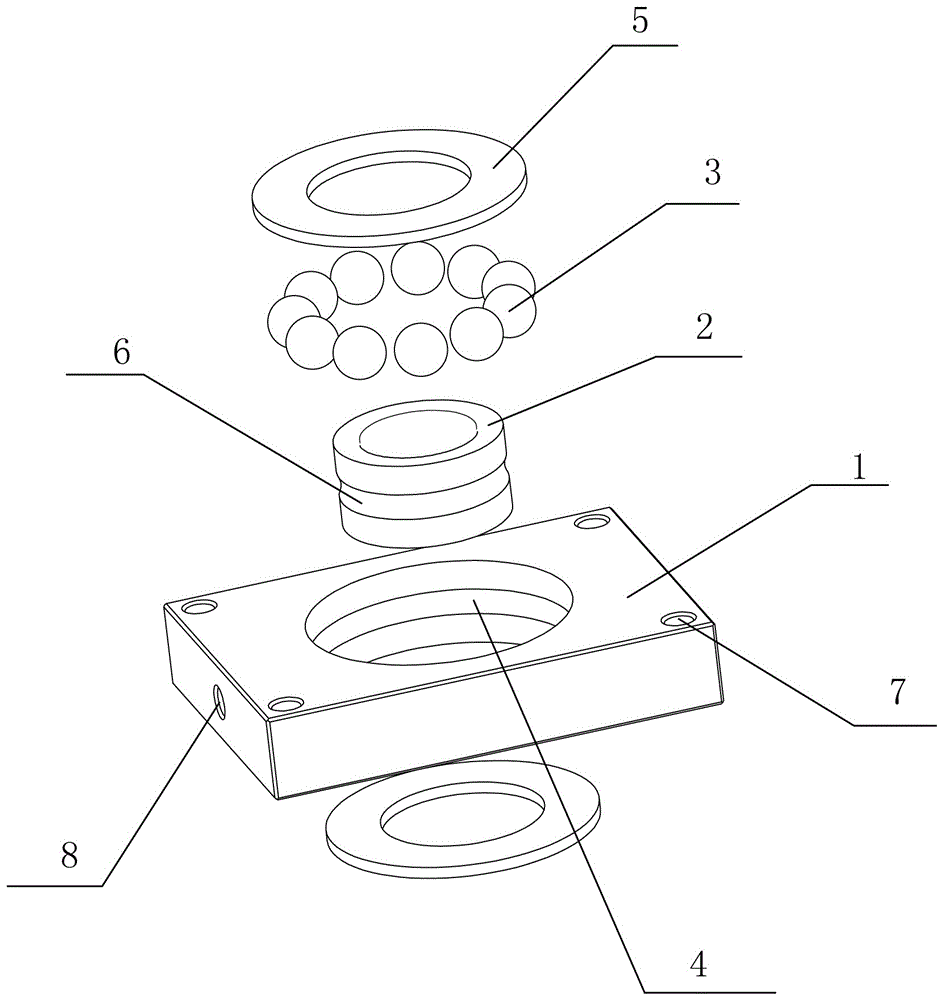

[0016] refer to figure 1 As shown, a rectangular precise gap adjustment bearing in this embodiment includes an outer frame 1, an inner ring 2, balls 3 and two protective covers 5. The outer frame 1 is square and has a circular hole penetrating up and down in the middle. Through hole, the inner side wall of the circular through hole is provided with an outer ball groove 4, the inner ring 2 is arranged in the circular through hole, and the outer surface of the inner ring 2 is provided with an inner ball groove 6, so The balls 3 are arranged between the inner ring 2 and the outer frame 1, and are fixed to the inner ball groove 6 through the outer ball groove 4, and the two protective covers 5 are arranged on both sides of the inner ring 2, and are clamped with the outer frame 1 .

[0017] Explain the various parts of this embodiment:

[0018] 1) The four corners of the upper surface of the outer frame 1 are provided with installation through holes 7 , and the side surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com