Steel Tower Angle Steel Anti-Bending and Torsional Instability Reinforcing Device

A reinforcement device, a technology of iron tower angle steel, applied in the direction of towers, building types, buildings, etc., can solve problems such as complex stress, and achieve the effects of improving compressive bearing capacity, avoiding local damage, and preventing local and overall buckling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

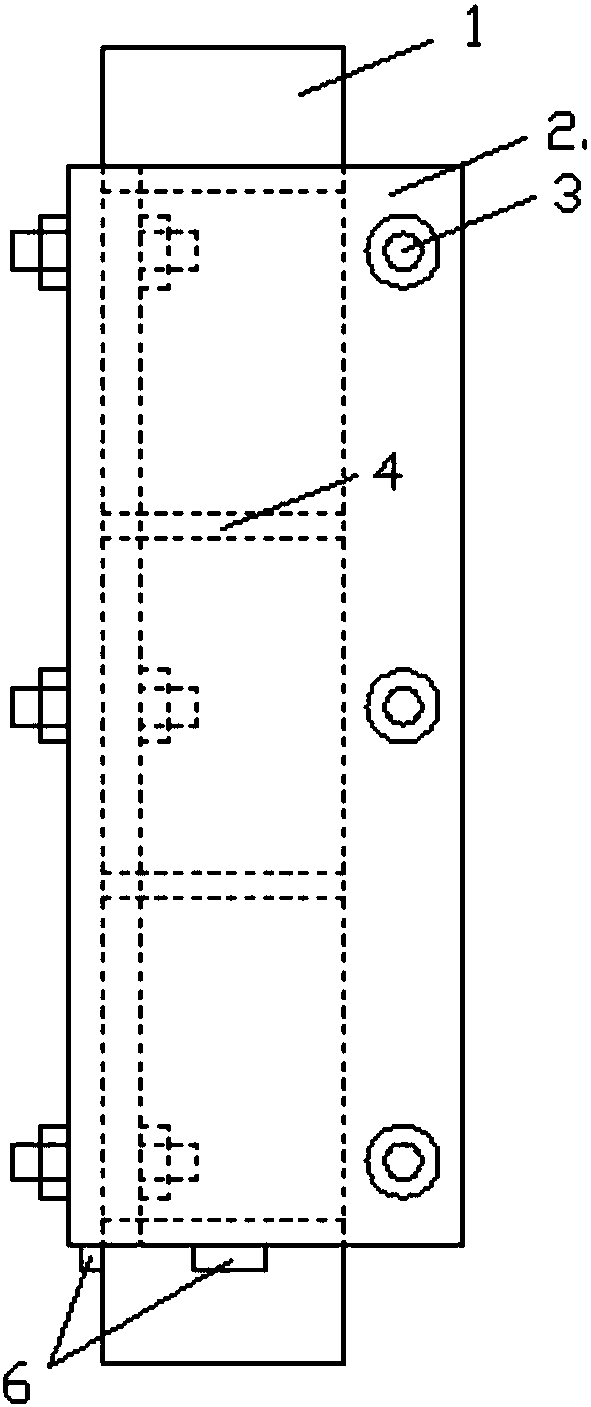

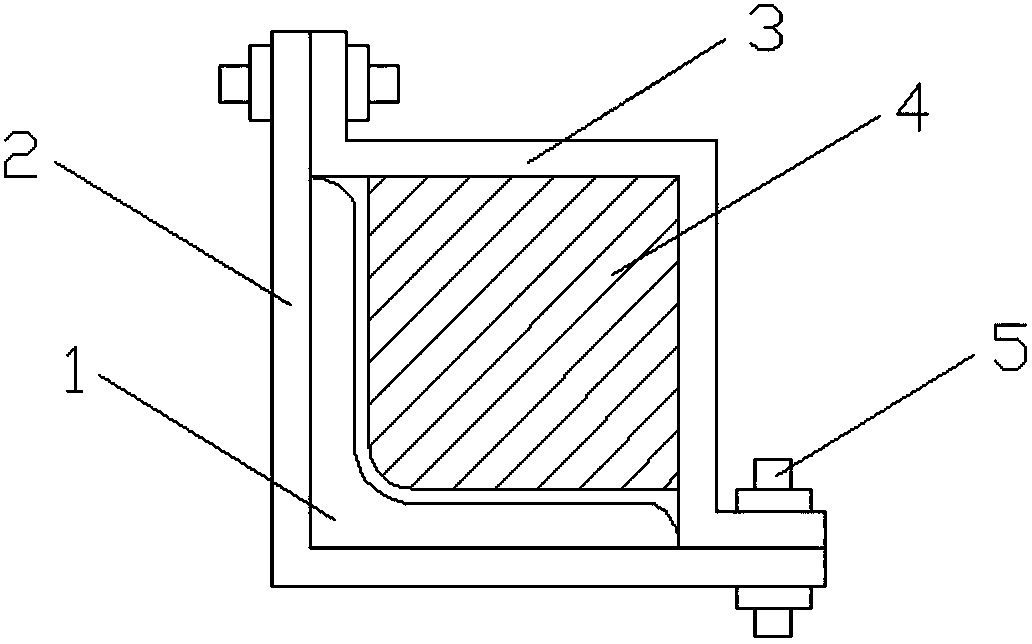

[0028] Such as figure 2 , 3 Shown: The anti-bending and torsional instability reinforcement device for the angle steel of the iron tower, including the restraint member 2, the ribbed restraint member 3 and several bolts 5, the restraint member is located on the outside of the angle steel 1, its leg width is greater than that of the angle steel leg, and at the edge of its leg width Bolt holes are set; the ribbed restraint member 3 is located inside the angle steel, opposite to the restraint member 2, and ribs 4 are arranged at intervals along the length direction. The limb width of the ribbed constraining member is approximately the same as that of the angle steel leg, and a 90° corner is set at the extremity of the ribbed constraining member 3, and bolt holes are set at the corner. The restraint member and the ribbed restraint me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com