Support structure assisting in cantilever beam construction and construction method

A support structure and cantilever beam technology, which is applied to bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of difficulty in secondary use of triangular brackets, increased costs, and waste of resources, so as to reduce construction costs. , The effect of strong turnover, easy installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

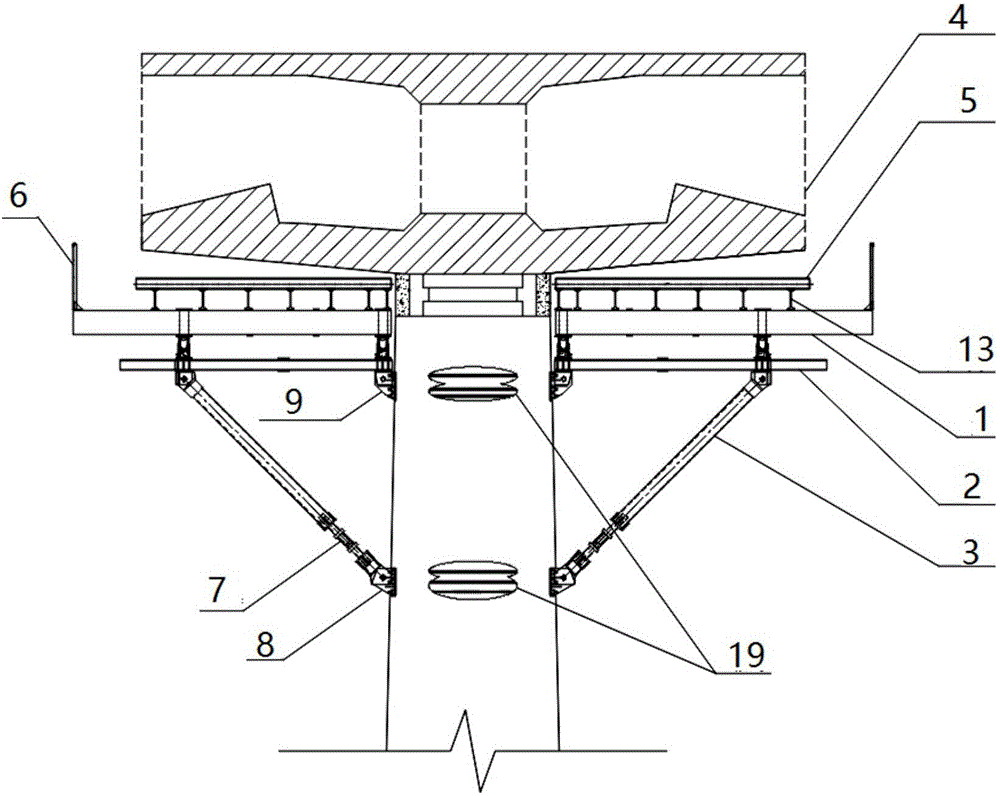

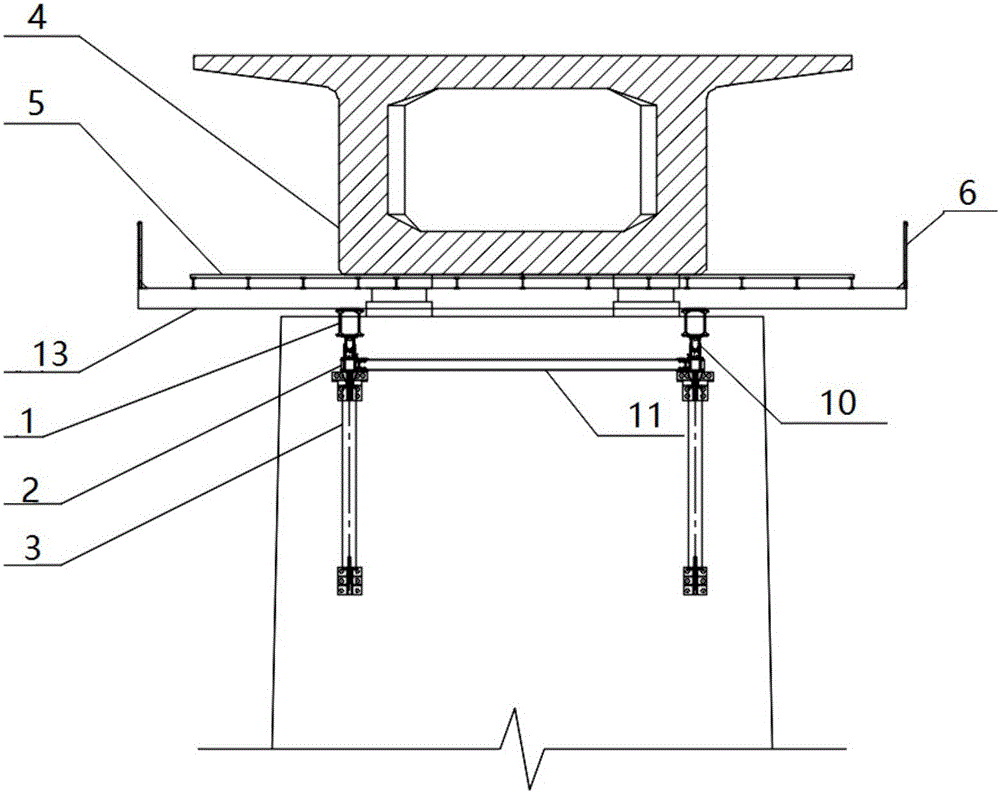

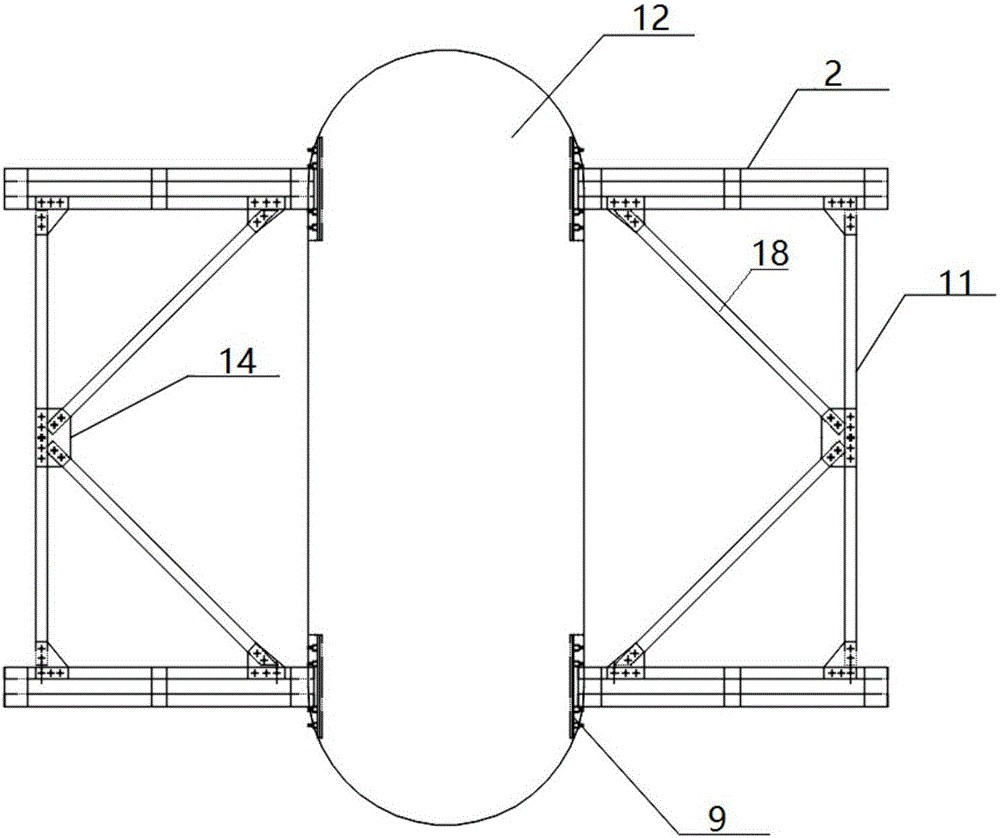

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

[0037] see Figure 1 to Figure 11 , the present invention comprises the supporting longitudinal girder 1 that is arranged on both sides of the pier 12, above the supporting longitudinal girder 1, a plurality of distribution beams 13 lined up in the direction of the bridge are arranged, the distribution beam 13 is provided with a formwork structure 5, and on the formwork structure 5 Place the cantilever beam 4, set two horizontal tie rods 2 on both sides of the bridge pier 12, the supporting longitudinal beam 1 connects the horizontal tie rod 2 through the sand box support 10, one end of the horizontal tie rod 2 is fixed on the pier 12, and the other end of the horizontal tie rod 2 passes through The oblique support rod 3 is hinged on the pier 12, the pier 12, the horizontal tie rod 2 and the oblique support rod 3 form a triangular bracket structure, and the horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com