Method for regulating and controlling transmittance of chrysotile nano-fiber films by gap filling

A fiber serpentine and nanofiber technology is applied in the field of adjusting the transmittance of fiber serpentine nanofiber films by using void filling, and can solve problems such as improving and regulating the transmittance of fiber serpentine nanofiber films that have not yet been seen. , to improve the transmittance and reduce the effect of Rayleigh scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

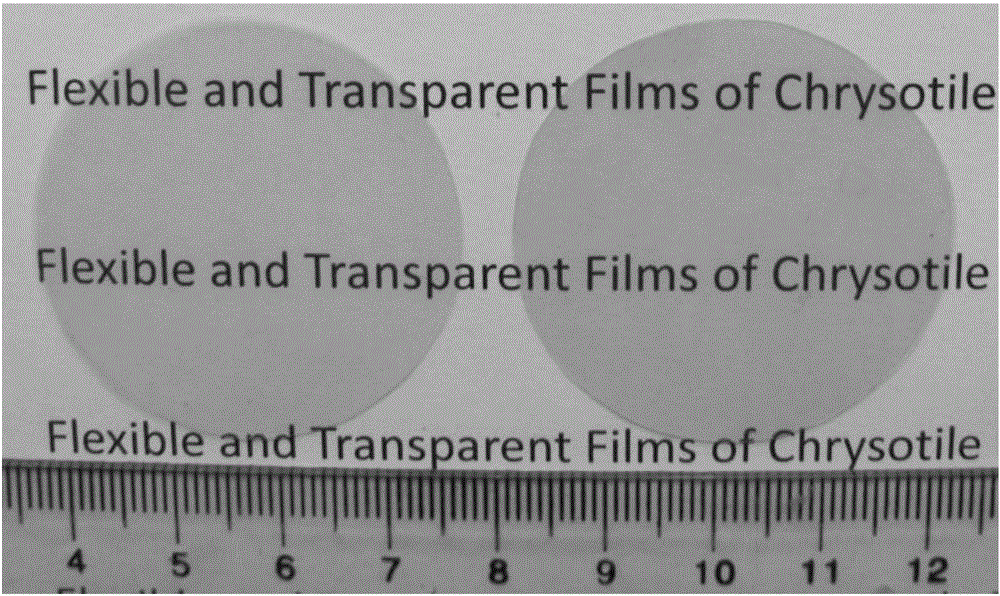

[0031]Take a white chrysotile nanofiber film with a thickness of about 50 μm, vacuum impregnate it in a photocurable resin system with bis-pentaerythritol hexaacrylate as the main component with a refractive index of 1.496 after curing for 24 hours, and then remove the excess resin on the surface , and then UV-cured, the light transmittance of the chrysotile nanofiber film can be increased to 78.22% (at 590nm); take a white chrysotile nanofiber film with a thickness of about 70 μm, and vacuum impregnate it in the cured refractive index. 1.542 in the photocurable resin system with o-phenylphenoxyethyl acrylate and ethoxylated bisphenol A dimethacrylate as the main components for 12 hours, then take out and remove the excess resin on the surface, and then carry out ultraviolet curing, which can be The light transmittance of the chrysotile nanofiber film is increased to 84.46% (at 590nm); the white chrysotile nanofiber film with a thickness of about 40 μm is vacuum-impregnated in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com