A special sticky mouth grinding machine for printing cartons

A grinding machine and sticking technology, applied in the direction of grinding frame, grinding machine, grinding bed, etc., can solve the problems of inability to bond tightly, poor surface, low efficiency, etc., and achieve the goal of improving production efficiency and improving integrity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

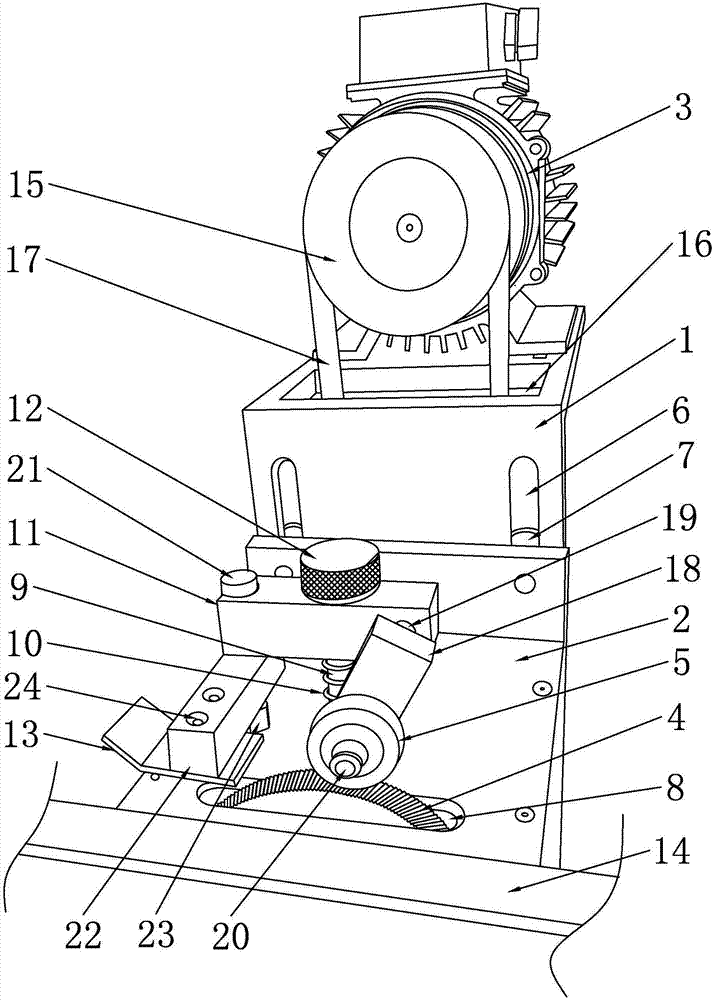

[0014] refer to figure 1 , a kind of glue grinding machine specially used for printing cartons, which includes a machine base 1 for installing various components, the machine base 1 is equipped with a grinding wheel frame 2 and a driving device 3, and the grinding wheel frame 2 is provided with a Grinding wheel 4 with a sticky mouth, the grinding wheel 4 is tooth-shaped; a pressure wheel 5 is arranged directly above the grinding wheel 4 to be in close contact with the grinding wheel 4, so as to compress the paper when grinding, and the degree of compression can be adjusted according to the thickness of the paper and actual needs The driving device 3 is a pulley driving device, and the belt pulley 15 below the support 1 of the driving device 3 has a belt through hole 16, and the belt 17 of the driving device 3 passes through the belt through hole 16 to connect and drive the emery wheel 4 Rotate, transfer torque, and finish grinding.

[0015] The machine base 1 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com