A double-function buffer cylinder for a forging manipulator

A forging manipulator and buffer cylinder technology, applied in the field of hydraulic buffer cylinders, can solve the problems of increasing the load of the forging manipulator, complex structure of the buffer cylinder, limiting the flexibility of clamp movement, etc., and achieves the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

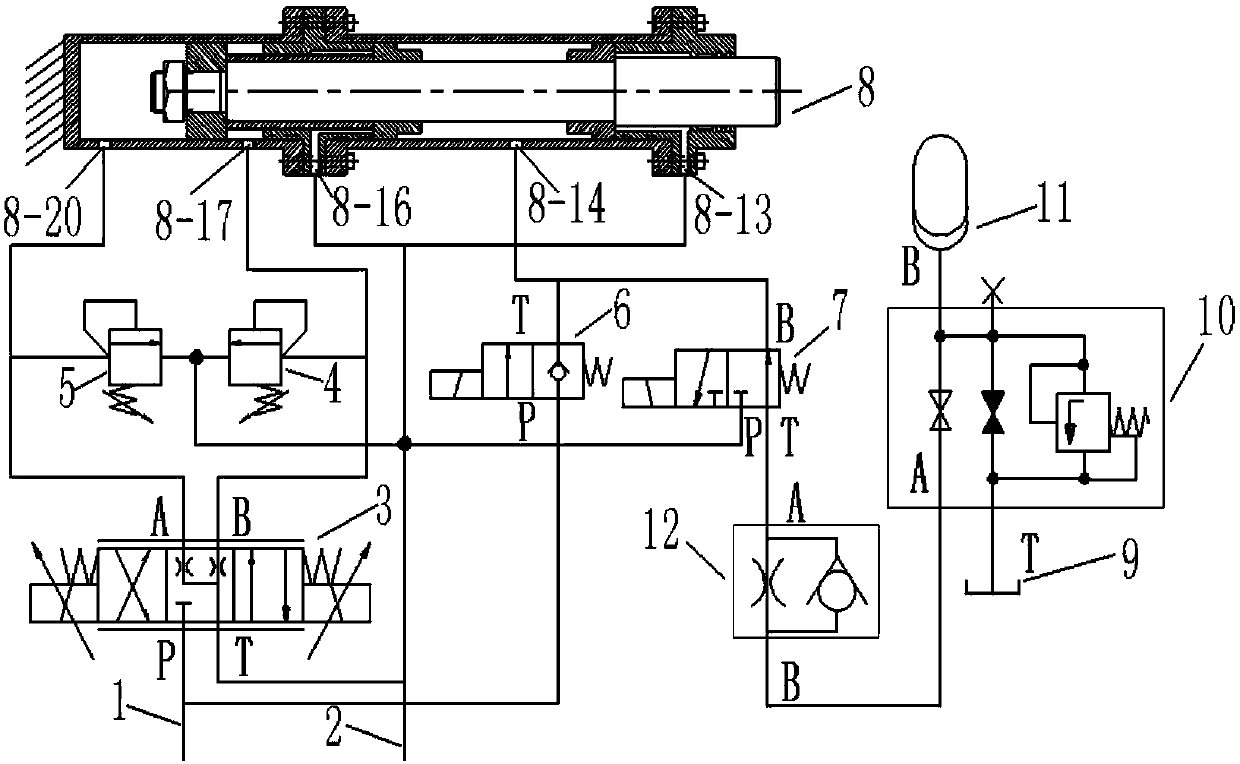

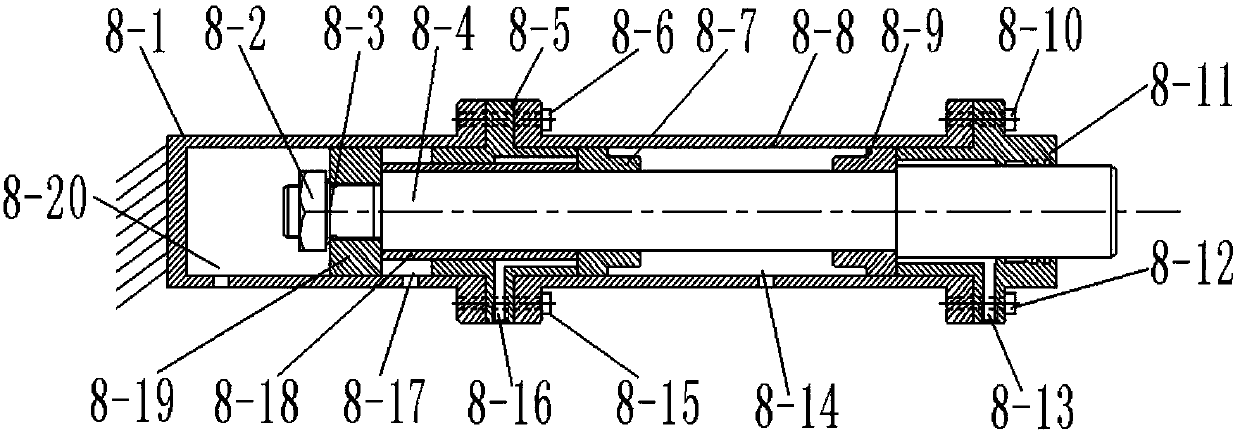

[0013] exist figure 1 In the schematic diagram of the present invention shown, the oil inlet P of the proportional directional valve 3 is connected to the oil supply port 1 of the oil source, and the A port of the proportional directional valve 3 is respectively connected to the inlet of the overflow valve II5 and the first cavity 8 of the buffer cylinder. -20 connection; port B of proportional directional valve 3 is respectively connected to the inlet of relief valve I4 and the second chamber 8-17 of the buffer cylinder; oil source return port 2 is respectively connected to the outlet of relief valve I4, the outlet of relief valve II5, The oil return port T of the directional valve 3, the P port of the two-position three-way reversing valve 7, the third chamber 8-16 of the buffer cylinder, and the fifth chamber 8-13 of the buffer cylinder are connected; the fourth chamber 8-14 of the buffer cylinder is respectively connected to the electromagnetic The T port of the ball valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com