Application of amino acid as hydrate accelerant and application of amino acid as hydrate accelerant in capturing and sealing of carbon dioxide

A technology of hydrate accelerator and carbon dioxide, which is applied in the direction of chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of low gas storage capacity, slow hydrate formation speed, high production cost, etc. The effect of high air density and fast capture speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

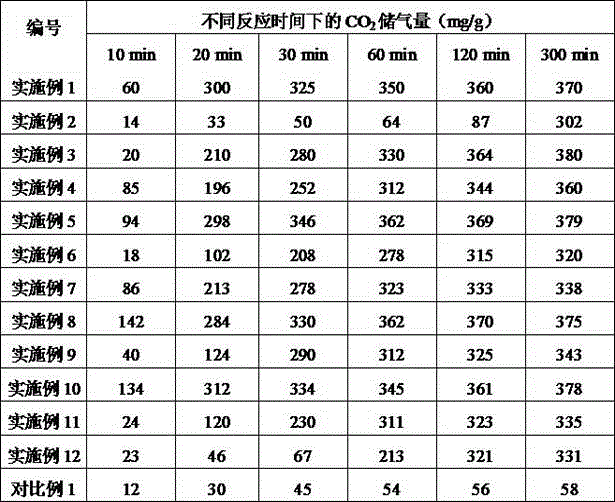

[0024] In this example, methionine with a mass fraction of 0.2% was used as a kinetic accelerator.

[0025] 1) Uniformly mix 0.2g methionine and 99.8 g water to obtain an aqueous solution of methionine with a mass fraction of 0.2%;

[0026] 2) Add 100 g of the methionine aqueous solution into the autoclave (effective volume 500 mL);

[0027] 3) At a temperature of 273 K, fill the autoclave with CO at a pressure of 3.3 MPa 2 Gas, calculated by the change of pressure in the reactor for a certain time interval CO 2 The gas hydrate storage capacity is shown in Table 1.

Embodiment 2

[0029] In this example, norleucine with a mass fraction of 0.01% was used as a kinetic accelerator.

[0030] 1) Uniformly mix 0.01g norleucine and 99.99 g water to obtain an aqueous solution of norleucine with a mass fraction of 0.01%;

[0031] 2) Add 100 g of the norleucine aqueous solution into the autoclave (500 mL effective volume);

[0032] 3) At a temperature of 270 K, fill the autoclave with CO at a pressure of 4 MPa 2 Gas, calculated by the change of pressure in the reactor for a certain time interval CO 2 The gas hydrate storage capacity is shown in Table 1.

Embodiment 3

[0034] In this example, norleucine with a mass fraction of 0.2% was used as a kinetic accelerator.

[0035] 1) Uniformly mix 0.2g norleucine and 99.8 g water to obtain an aqueous solution of norleucine with a mass fraction of 0.2%;

[0036] 2) Add 100 g of the norleucine aqueous solution into the autoclave (500 mL effective volume);

[0037] 3) At a temperature of 273 K, fill the autoclave with CO at a pressure of 3.4 MPa 2 Gas, calculated by the change of pressure in the reactor for a certain time interval CO 2 The gas hydrate storage capacity is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com