Anti-infection hemodialysis pipe and use method thereof

A hemodialysis tube and anti-infection technology, applied in the field of medical devices, can solve the problems of increasing the medical burden of patients and complications related to re-insertion, poor anti-infection performance of the hemodialysis tube, and the failure of the dialysis tube to prevent blood backflow. The effect of medical burden, prolonged indwelling time, and reduced chance of associated infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

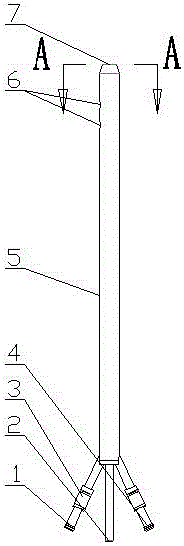

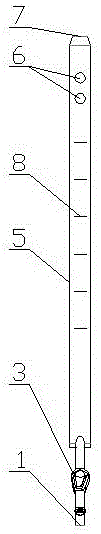

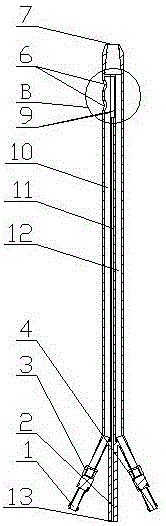

[0037] refer to Figure 1~4 : An anti-infection hemodialysis tube of the present embodiment, comprising a main body 5, a clamp switch 3, a sealing plug 13 and a heparin cap; the front end of the main body 5 is provided with a blood return port 7 communicating with the venous cavity 12, and the blood backflow The port 7 is used to reinfuse blood; the side wall of the main body 5 near the end of the blood return port 7 is provided with two blood drainage ports 6 connected to the arterial cavity 10, and the blood drainage port 6 is used to drain blood out of the body; the main body 5 The end of the end is provided with a vein end 4, an artery end 1 and a water injection end 2 connected to the water injection chamber 11; a sealing plug 13 is nested in the water injection end 2; a water bag 9 is provided at the end of the water injection chamber 11; The pipeline connecting the venous end 4 with the venous cavity 12 and the pipeline connecting the arterial end 1 with the arterial ca...

Embodiment 2

[0043] A method for using the anti-infection hemodialysis tube of this embodiment, using the anti-infection hemodialysis tube as described in Example 1, comprises the following steps:

[0044] 1) Pre-puncture work and guide wire implantation into blood vessels, the guide wire penetrates from the blood return port 7 into the transvenous cavity 12 and then passes through the vein end 4;

[0045] 2) After the anti-infection hemodialysis tube enters the blood vessel along the guide wire, observe the upper scale of the main tube body 5 to the corresponding position, take out the guide wire, and close the clamp switch 3;

[0046] 3) Fix the anti-infection hemodialysis tube, connect the arterial end 1 and the venous end 4 at the end of the main body 5 to the corresponding external instruments, and open the clamp switch 3;

[0047] 4) After hemodialysis, inject 5ml and 6ml of tube lock solution 15 from the arterial end 1 and venous end 4 of the anti-infection hemodialysis tube respect...

Embodiment 3

[0052] Compared with Example 2, the method for using the anti-infection hemodialysis tube of this embodiment has the following differences:

[0053] In step 4), the lock solution 15 is prepared by mixing 10 ml of hypertonic saline with a Nacl content of 10% (w / w) and 8 mg of heparin sodium.

[0054] In step 5), the dosage of the physiological saline 16 is 8ml.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com