Direct-action type lateral flow regulator

A flow regulator, direct-acting technology, applied in horticulture, botany equipment and methods, cultivation, etc., can solve the problems of not being able to adapt to low-pressure drip irrigation systems, high pressure adjustment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

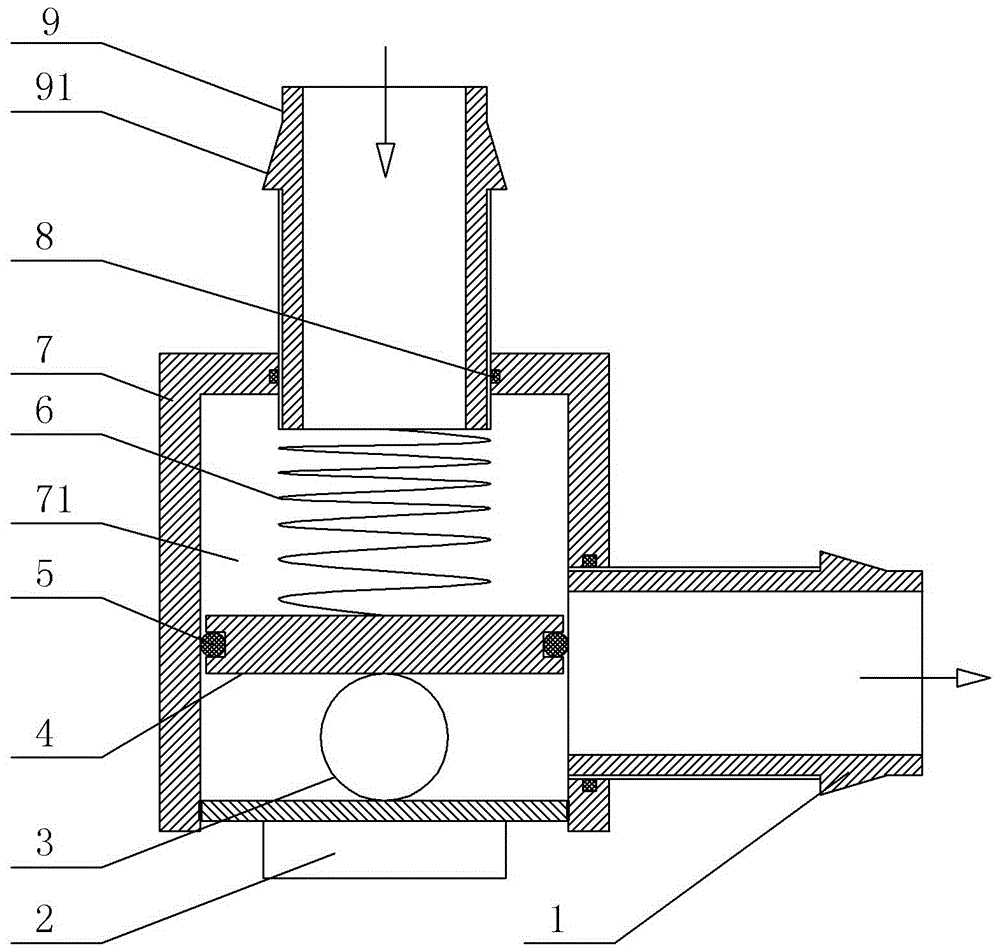

[0015] The reference signs in the drawings of the specification include: water outlet joint 1, end cover 2, rubber ball 3, piston disc 4, piston sealing ring 5, tension spring 6, housing 7, sealing ring 8, water inlet joint 9, inner Cavity 71, barb 91.

[0016] The embodiment is basically as figure 1 Shown: direct acting capillary flow regulator, including water inlet joint 9, water outlet joint 1 and valve core, water inlet joint 9 is used to connect the water inlet pipe, water outlet joint 1 is used to connect the water outlet pipe, water inlet joint 9 and water outlet joint 1 are hollow tubular. A vertical cylindrical inner chamber 71 is provided inside the housing 7 . Such as figure 1 As shown, the upper end of the housing 7 is screwed to the lower end of the water inlet joint 9 , and the water inlet joint 9 communicates with the inner chamber 71 of the housing 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com