Intelligent dual-step double-precision weighing sensor

A weighing sensor, intelligent technology, applied to the detailed information of weighing equipment, weighing equipment using elastically deformable parts, instruments, etc., can solve the problems of large errors, inability to be used for other purposes, and inability to be used as a weight scale, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

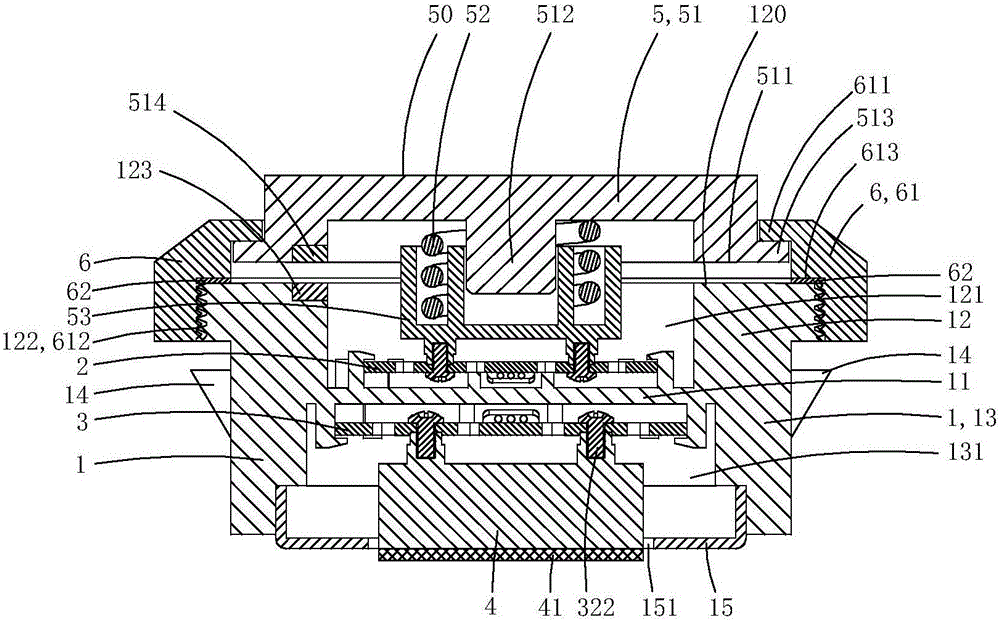

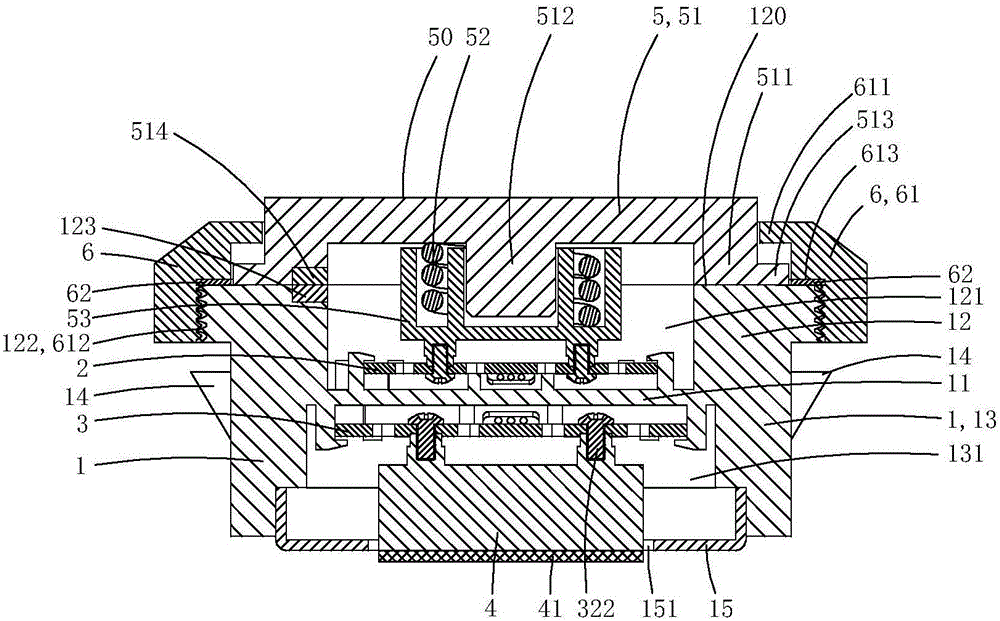

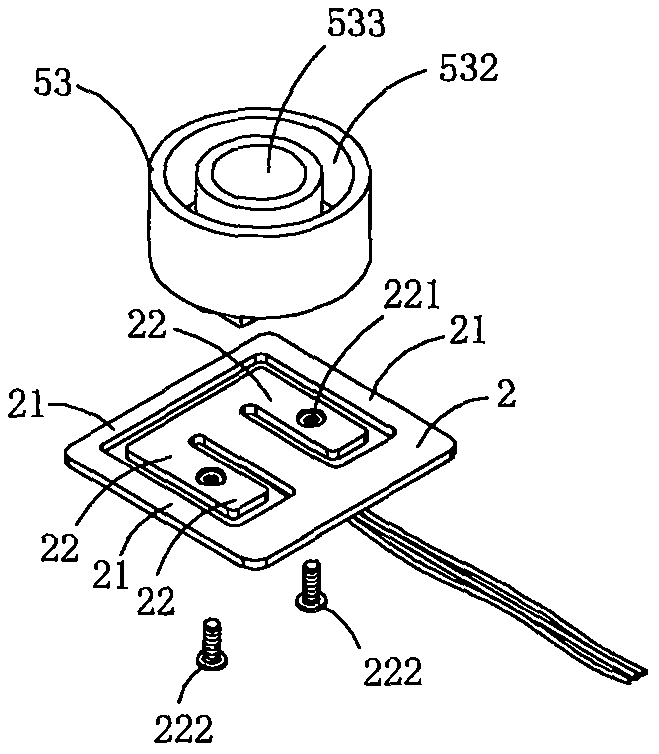

[0015] This embodiment is an adjustable double-stage double-precision load cell, see Figure 1 to Figure 6 As shown, it includes a mounting base 1, a first precision load cell 2, a second precision load cell 3, a support foot 4, an elastic support 5 and an adjustment mechanism 6 for adjusting the height of the elastic support.

[0016] The mounting seat is provided with a mounting plate portion 11 and a force guiding support portion 12 for transmitting the pressure received by itself to the mounting plate portion; an elastic support member, a first precision load cell, a mounting plate portion, and a second precision weighing The sensor and supporting feet are crimped and set in sequence.

[0017] The installation board part is arranged horizontally, the first card holder is arranged on the top wall of the installation board part, and the second card holder is arranged on the bottom wall. The existence of the first deck and the second deck can make the installation operation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com