Self-locking device of lifting hooks

A technology of self-locking device and hook, which is applied in the field of heating furnace, can solve the problems of affecting the working efficiency of the production line, harsh working environment, and low hoisting efficiency, so as to facilitate design and manufacture and wide-scale promotion and use, reduce loading and unloading time, and improve loading and unloading efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further illustrate the technical means adopted by the present invention and the technical effects achieved, the following will be described in detail in conjunction with the accompanying drawings and embodiments.

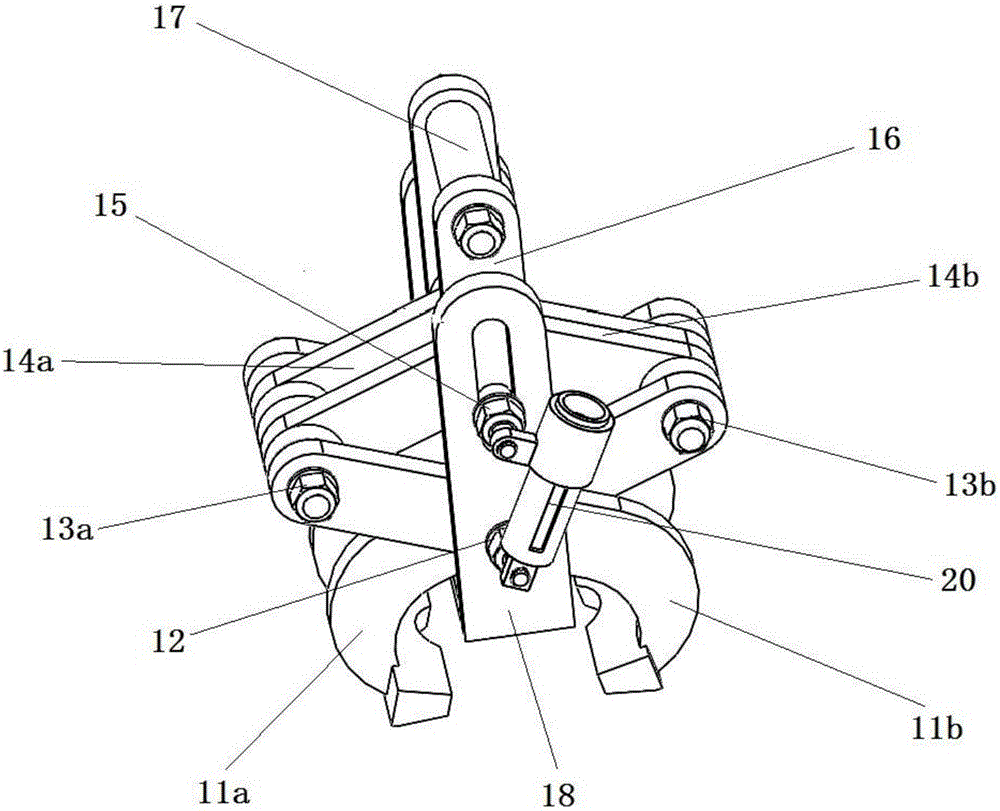

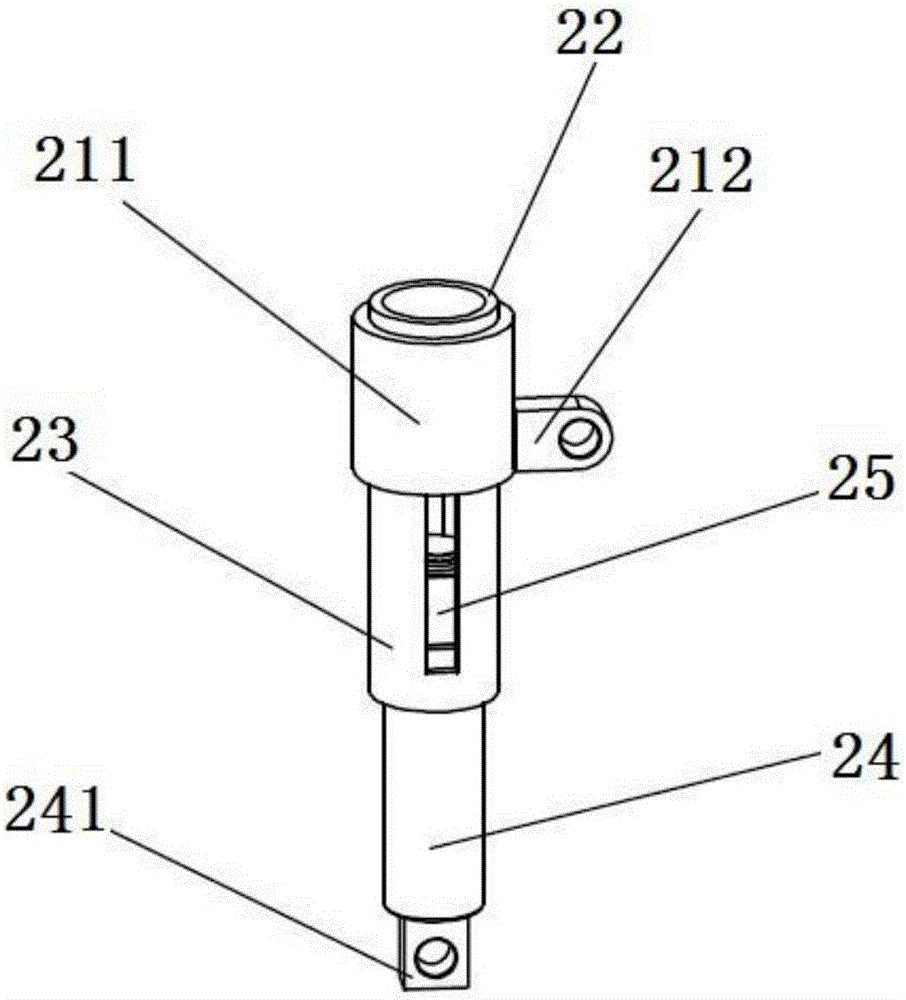

[0034] refer to Figure 1 to Figure 5 , is the hook self-locking device of the present invention, which includes a clamping part 10 and a self-locking part 20 . The clamping part 10 includes a first hook 11a, a second hook 11b, a first connecting shaft 12, a first rotating shaft 13a, a second rotating shaft 13b, a first connecting rod 14a, a second connecting rod 14b, The second connecting shaft 15 , the fixed rod 16 , the third connecting shaft 17 and the striker 18 . Wherein the first hook 11a and the second hook 11b are symmetrically arranged in a scissors shape, and the first connecting shaft 12 is located at the joint of the two hooks. The first rotating shaft 13a and the second rotating shaft 13b are respectively arranged on the top ends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com