Vertical stand-alone energy-saving vacuum brick extruder

An extruder and vertical technology, which is applied in the field of vertical stand-alone energy-saving vacuum brick-making extruders, can solve the problems of large useless power consumption and huge volume, and achieve the effect of reducing supporting power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

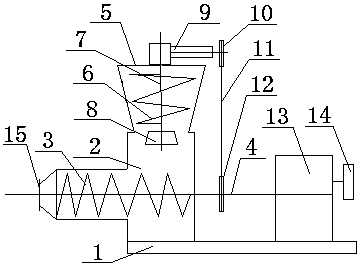

[0014] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment comprises body 1, and body 1 side is provided with vacuum chamber 2, and vacuum chamber 2 is provided with horizontal auger 3, and horizontal auger 3 is installed on the main shaft 4, and above vacuum chamber 2 is provided with material box 5, material box 5 A vertical auger 6 is provided inside, and the vertical auger 6 is installed on the rotating shaft 7 . An adjustable cone 8 is provided below the vertical auger 6 . Rotating shaft 7 is connected with 90 degree angle speed changer 9, and 90 degree angle speed changer 9 is connected with upper transmission wheel 10, and upper transmission wheel 10 is connected with lower transmission wheel 12 by transmission chain 11, and lower transmission wheel 12 is installed on the main shaft 4. The main shaft 4 is connected with a speed reducer 13, and the speed reducer 13 is connected with a clutch wheel 14. The end of the horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com