Control method for regulating fuel supply of SCV combustor

A technology of fuel supply and control method, which is applied in the direction of adjusting fuel supply, combustion method, and combustion control, and can solve the problems of lag in the output change of the burner.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

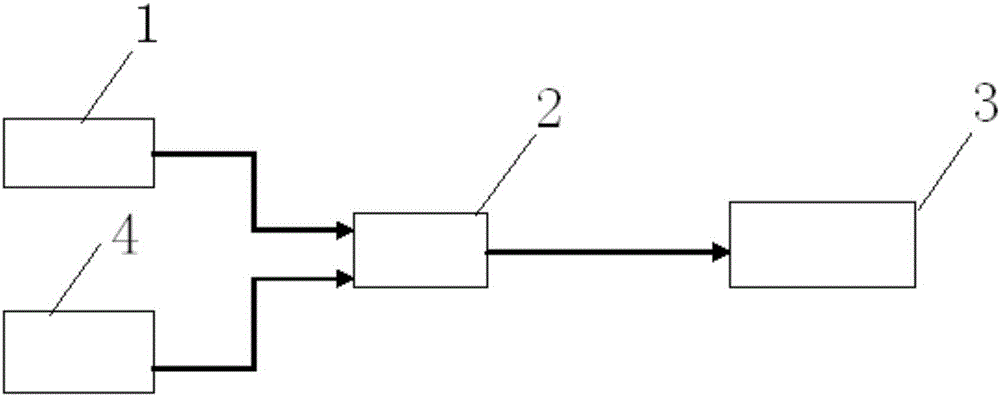

[0011] Such as figure 1 As shown, a control method for adjusting the fuel supply of the SCV burner: the steps of the method are as follows:

[0012] 1. The LNG flow rate is detected by the LNG flow meter 1 and input to PLC2. PLC2 takes the LNG flow rate as the input value X, and calculates the opening value Y1 of the natural gas regulating valve 3 through the formula Y1=aX+b. The formula Y1=aX +b From the discrete point data formed by the LNG flow of different loads corresponding to different natural gas regulating valve 3 opening values in the field test, these discrete point data are connected into a curve, and the linear formula Y1=aX closest to the curve is found by calculation +b, so that any LNG flow value X can calculate its corresponding natural gas regulating valve 3 opening value Y1;

[0013] 2. Input the actual NG temperature value to PLC2 through the NG temperature transmitter 4, and calculate the opening value Y2 of the natural gas regulating valve 3 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com