Installation and vertical gap-adjusting method for crank arm beams of self-lifting outrigger rollover system of bridge pier stud

A pier column and self-elevating technology, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of poor installation effect and inability to install the curved arm beam 1 and the reinforced horizontal back corrugated 3, so as to speed up the installation efficiency, Easy to disassemble and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

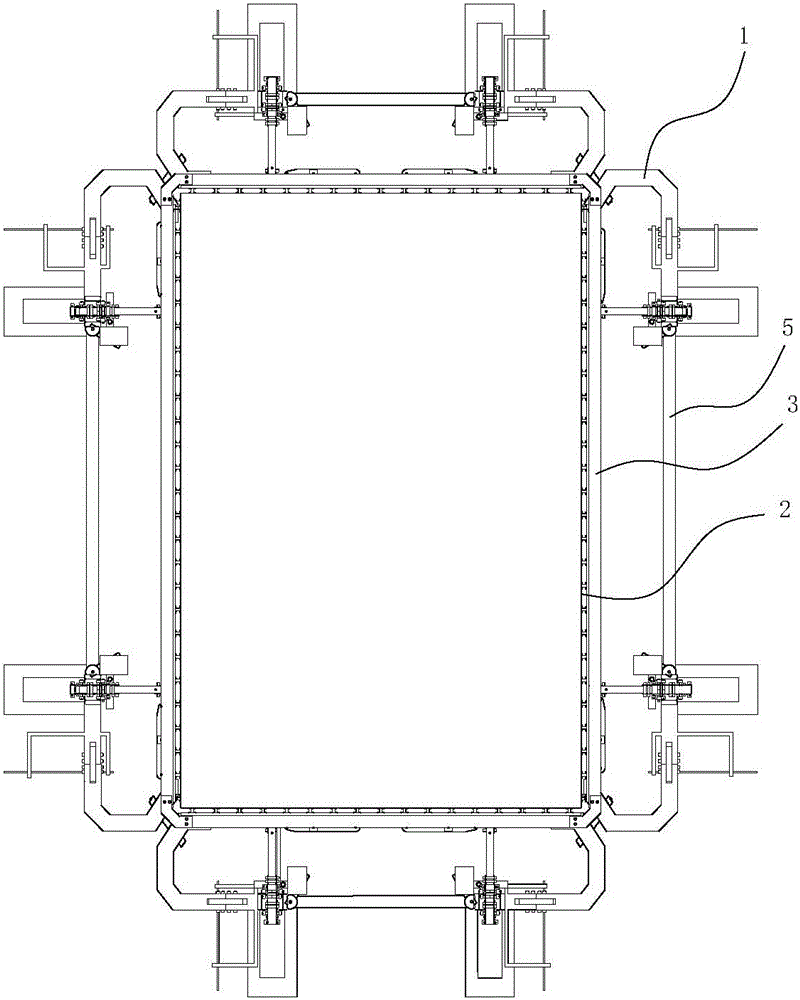

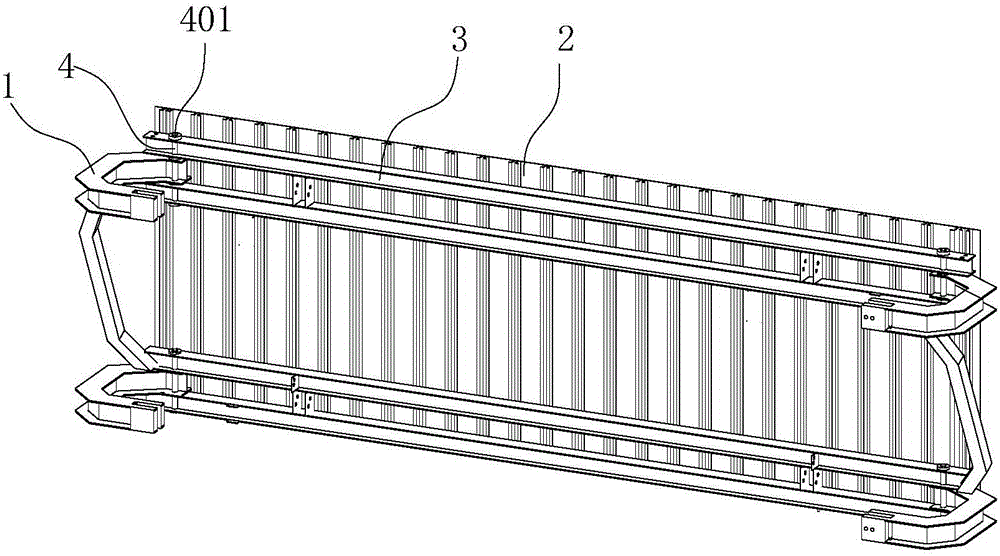

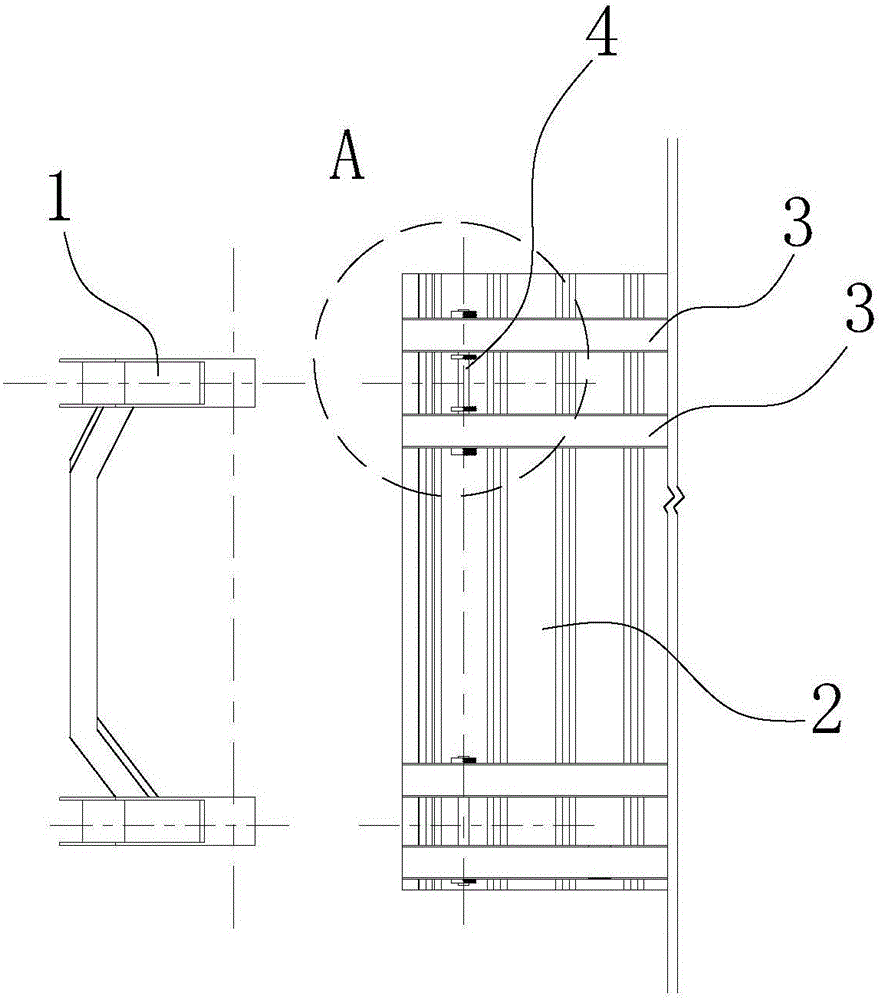

[0027] The vertical distance adjustment method for the curved arm beam installation of the bridge pier column self-elevating outer frame turning system according to the present invention is applied to the adjustment of the crank arm beam of the bridge pier column self-elevating outer frame turning system. The outer frame turning system includes a formwork 2, and the outer surface of the formwork 2 is provided with at least two reinforced transverse back flutes 3 and adjusting bolts 4; the reinforced transverse back flutes 3 have at least two, and the adjacent two Reinforced horizontal back flute 3 and parallel to each other; one end of the reinforced horizontal back flute 3 connected to the curved arm beam 1 is provided with a vertical through hole, and one end of the curved arm beam 1 connected to the reinforced horizontal back flute 3 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com