Manufacturing method of farm automatic manure-scraping machine

A production method and farm technology, applied in animal houses, poultry farming, poultry cages or houses, etc., can solve the problems of not being able to meet the needs of large-scale breeding, high labor intensity, bad smell, etc., and achieve structural Simple, easy to operate, and achieve intelligent effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

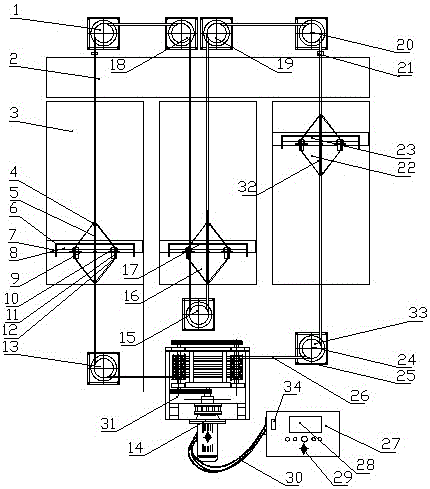

[0013] Preferred embodiments of the present invention are described below in conjunction with accompanying drawings, as figure 1 As shown, the manufacturing method of an automatic manure scraper for a farm of the present invention is driven by a 380V, 2.2kW Sanxiang Motor power supply, and one host can run three manure scraper devices (32). A manufacturing method of an automatic manure scraper for farms is to adopt three manure scraper devices (32) along one belt, so as to improve the efficiency of manure cleaning.

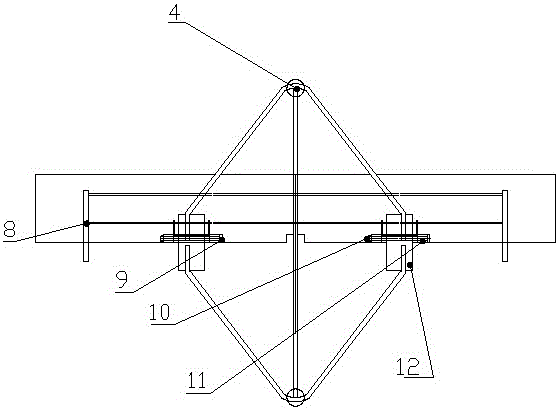

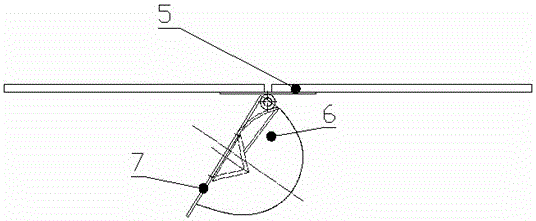

[0014] The invention relates to a manufacturing method of an automatic manure scraper for farms. The manure scraper device (32) consists of a manure board tie rod (5), a manure board left and right reinforcement board (6), a manure scraper reinforcement board (8), and a pin shaft (9), cotter pin (10), pin cover (11) and manure plate tie rod support plate (12), there is a connecting frame on the manure scraping plate (32), and a manure plate tie rod (5) is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com