Power strip assembly convenient to use

A technology of plug-in strips and components, which is applied to the parts of connecting devices, electrical components, devices with flexible leads, etc., can solve the problems of unsatisfactory use of plug-in strips, and achieve good use effects, good safety, and high conductivity. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other; the present invention will be described in detail below with reference to the accompanying drawings and in combination with the embodiments.

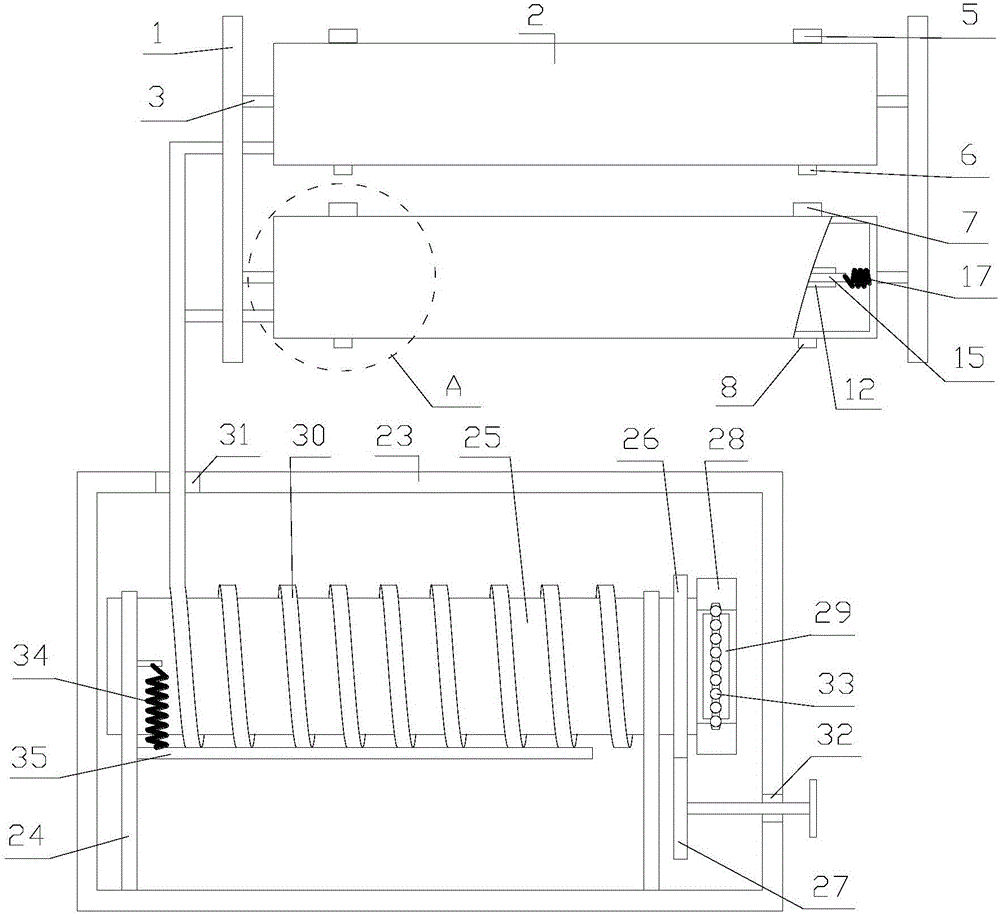

[0049] refer to figure 1 , 2 , 3:

[0050]An easy-to-use plug-in assembly proposed by the present invention includes two supports 1, two plug-in mechanisms, a plurality of shielding units, a box body 23, a bracket 24, a rotating shaft 25, a first gear 26, and a second gear 27 , a handle, a third conductor 28, a fourth conductor 29, a first lead 30, a second lead, a plurality of steel balls 33, a third spring 34, and a cross bar 35.

[0051] The two supporting pieces 1 are arranged oppositely, the supporting pieces 1 are provided with sliding grooves, and the sliding grooves on the two supporting pieces 1 are arranged oppositely.

[0052] The two plug-in mechanisms ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com