Predication method of stress relaxation life of torsion spring

A torsion spring and stress relaxation technology, applied in the field of predicting the life of torsion springs, can solve problems such as torsion springs that have not yet been found, and achieve the effects of reducing test costs and cycles, good reliability, and high prediction accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

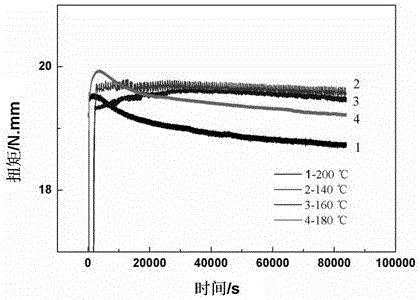

[0052] This embodiment adopts the torsion spring that adopts normalizing state beryllium bronze QBe2 to test, and the basic parameter of spring is: d 簧丝 =0.55mm, n=19, D 内径 = (2.4±0.25)mm. Before starting the test, first preheat the instrument for 1 h to eliminate the influence of the thermal expansion of the fixture on the test results. Four temperature points of 140°C, 160°C, 180°C and 200°C were selected as the test temperature. Because the spring wire is very thin, preheat the torsion spring for 5 minutes before loading. Then twist the spring at a torsion speed of 0.5° / s until the torsion angle is 65° and remains unchanged. The test duration is 24h. During the test, the computer automatically records the torque data every 1s.

[0053] At four temperature points of 140°C, 160°C, 180°C and 200°C, about 86,400 points were collected at each temperature point from the beginning of torsion to the end of the test, and representative points were selected at intervals of 7200 ...

Embodiment 2

[0059] Present embodiment adopts the torsion spring that adopts quenched state beryllium bronze QBe2 to test, and the basic parameter of spring is: d 簧丝 =0.55mm, n=19, D 内径 = (2.4±0.25)mm. Before starting the test, first preheat the instrument for 1 h to eliminate the influence of the thermal expansion of the fixture on the test results. Four temperature points of 140°C, 160°C, 180°C and 200°C were selected as the test temperature. Because the spring wire is very thin, preheat the torsion spring for 5 minutes before loading. Then twist the spring at a torsion speed of 0.5° / s until the torsion angle is 65° and remains unchanged. The test duration is 24h. During the test, the computer automatically records the torque data every 1s.

[0060] At four temperature points of 140°C, 160°C, 180°C and 200°C, about 86,400 points were collected at each temperature point from the beginning of torsion to the end of the test, and representative points were selected at intervals of 7200 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com