Yarn feeding bobbin direction changing deivce and bobbin supply system

A technology of direction conversion and supply system, which is applied in the directions of transportation and packaging, textile and papermaking, and conveying filamentous materials, etc. It can solve problems such as difficult space adjustment, bobbin detachment, and difficulty in realizing device miniaturization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

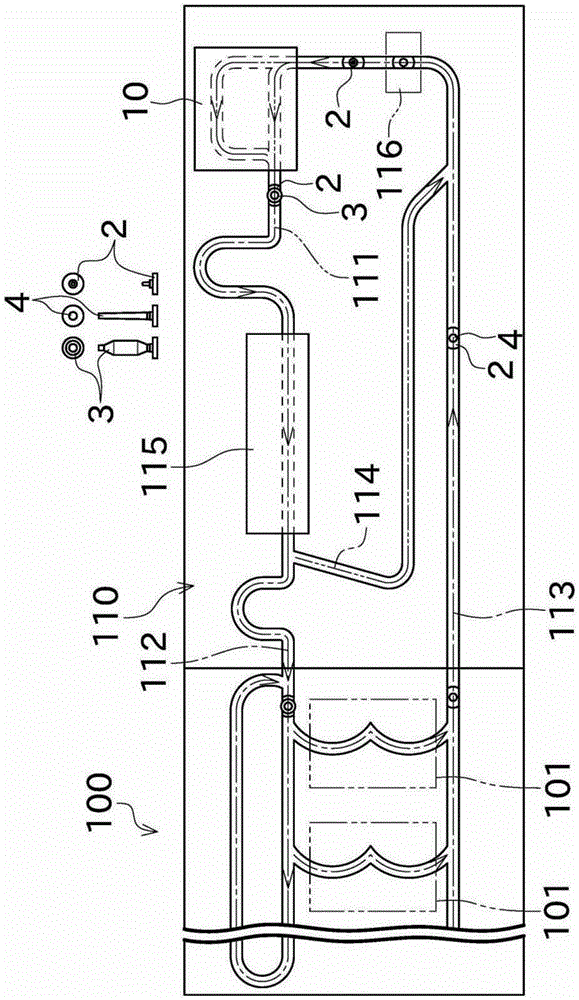

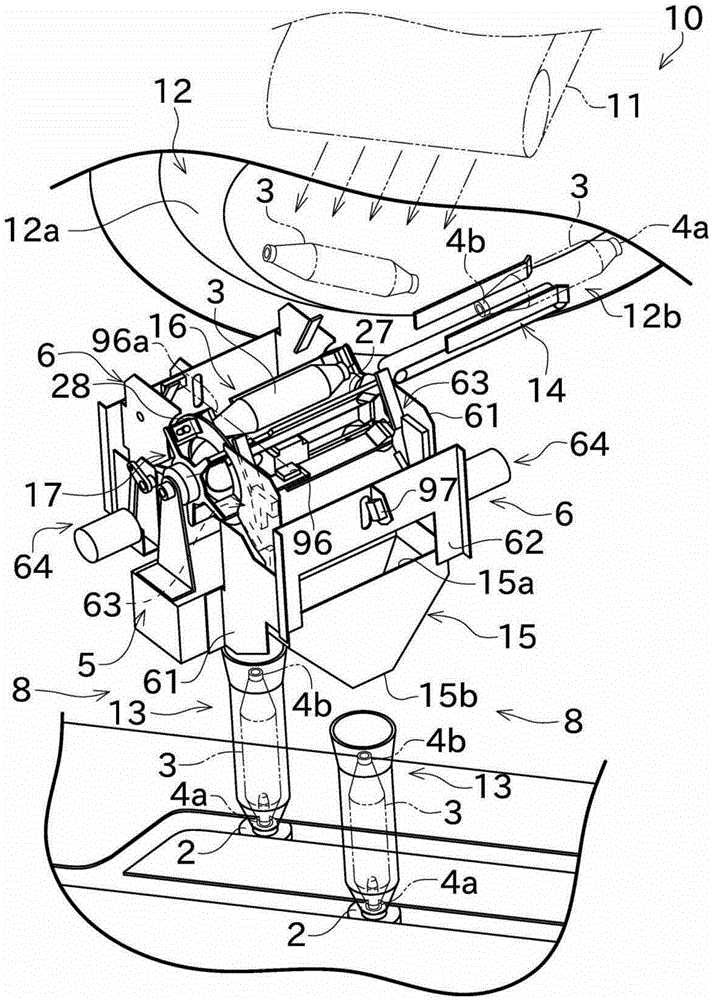

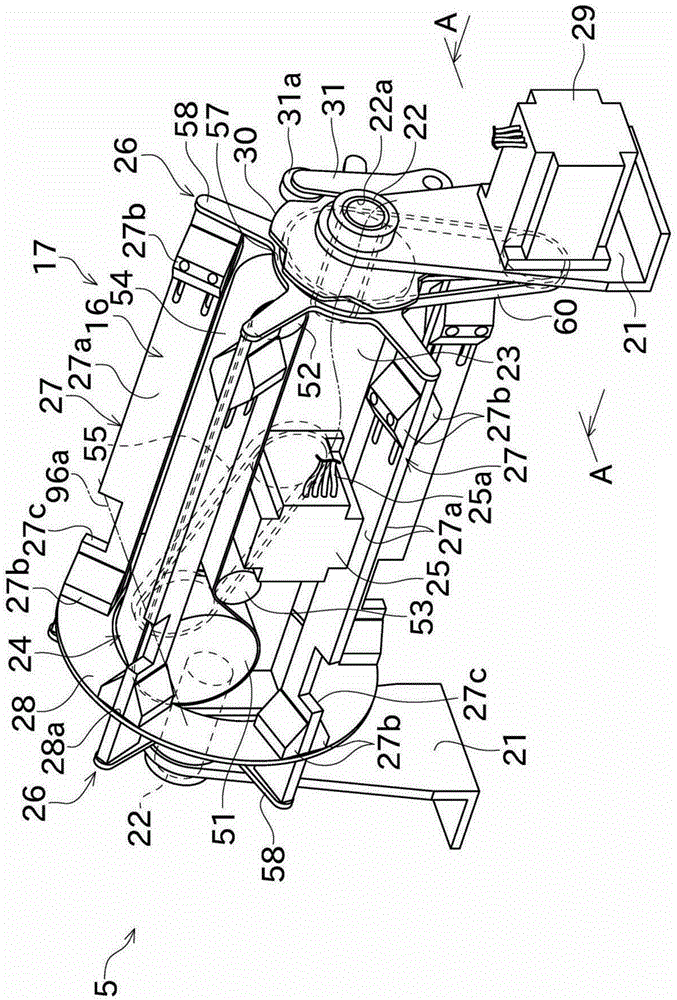

[0033] Next, embodiments of the present invention will be described with reference to the drawings. figure 1 It is a plan view showing a bobbin supply device 10 according to an embodiment of the present invention together with a tray conveyance path 110 and an automatic winder 100 . figure 2 It is a perspective view showing the overall configuration of the bobbin supply device 10 .

[0034] In the following description, "upstream" and "downstream" mean upstream and downstream with respect to the conveying direction of the yarn supplying bobbin 3 and the conveying tray (conveying means) 2.

[0035] figure 1 The illustrated bobbin supply device (bobbin supply system) 10 supplies a yarn supply bobbin 3 formed by winding a yarn around a core tube (winding bobbin) 4 to an automatic winder 100 .

[0036] The automatic winder 100 includes a plurality of winder units 101 arranged side by side. Each winder unit 101 unwinds the yarn from the supplied yarn supply bobbin 3 to form a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com