A liquid bridge generator with rotatable upper liquid bridge column

A generator and rotary technology, applied in the field of fluid physics, can solve the problems of manual measurement, can not be used to study the influence of liquid bridge, and affect the accuracy of the experiment, so as to improve the accuracy, increase the accuracy of the experiment, and have a simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following embodiments.

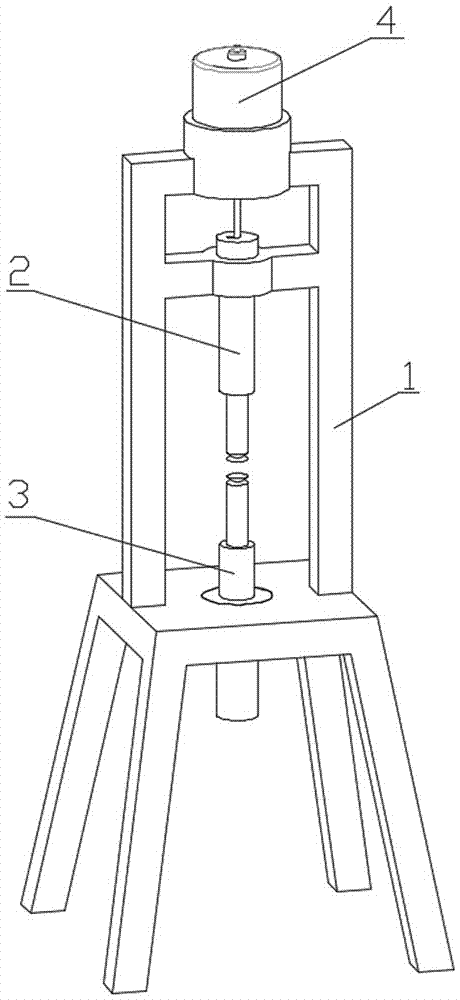

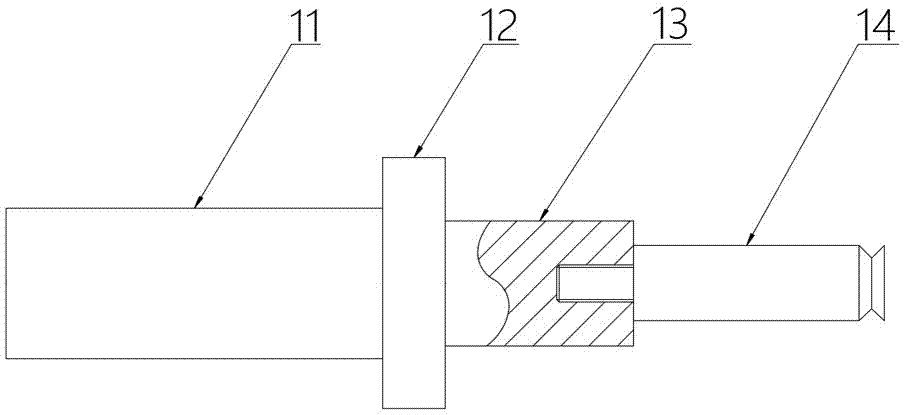

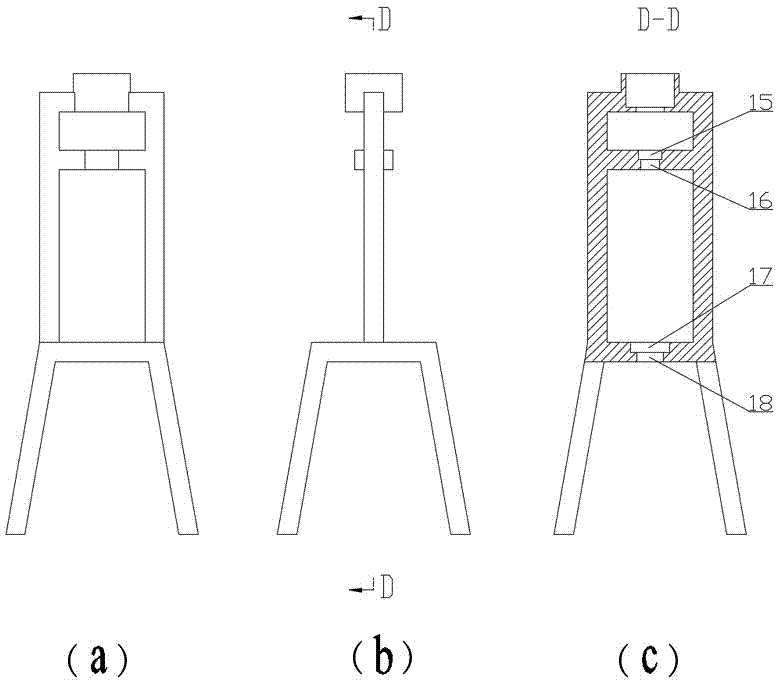

[0020] A liquid bridge generator with a rotatable upper liquid bridge column, such as figure 1 As shown, including bracket 1 (its structure is as Figure 4 As shown), the controllable speed motor 4 is installed on the upper part of the bracket, the upper liquid bridge column mounting hole 16 and the upper liquid bridge column clamping groove 15 are arranged on the bracket directly below the motor, the lower liquid bridge column mounting hole 18 and the lower The liquid bridge column clamping groove 17, the upper liquid bridge column 2 and the lower liquid bridge column 3 are installed vertically through the upper liquid bridge column mounting hole 16 and the lower liquid bridge column mounting hole 18 respectively and keep the center relative; the upper liquid bridge column...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com