Polycrystalline cubic boron nitride cutting tool material for finishing iron castings and preparation method thereof

A technology of polycrystalline cubic and boron nitride cutters, applied in metal processing equipment, transportation and packaging, etc., can solve problems such as poor surface finish of workpieces, difficulties in mixing and sintering, and achieve good impact resistance, fine particle size, The effect of high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A polycrystalline cubic boron nitride cutting tool material for finishing iron castings and a preparation method thereof, comprising the following steps:

[0022] (1) Put cubic boron nitride powder and metal powder into a vacuum furnace for physical vacuum treatment to remove moisture, oxygen and other impurities;

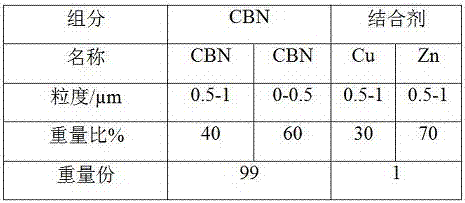

[0023] (2) Mix the cubic boron nitride micropowder treated in step (1) according to the need to take micropowders of different particle sizes according to weight parts to make cubic boron nitride mixture, and mix the metal powder treated in step (1) according to It is necessary to mix different types by weight to make metal powder mixture, and then mix cubic boron nitride mixture and metal powder mixture by weight to make polycrystalline cubic boron nitride tool material, cubic boron nitride See Table 1 for the specific components and proportions of metal powder and metal powder.

[0024] Table 1 Component distribution ratio of PCBN tool materials

[0025]...

Embodiment 2

[0031] The polycrystalline cubic boron nitride cutting tool material and preparation method of the iron casting finishing machining of the present embodiment are as follows:

[0032] (1) Put cubic boron nitride powder and metal powder into a vacuum furnace for physical vacuum treatment to remove water, oxygen and other impurities;

[0033] (2) Mix the cubic boron nitride micropowder treated in step (1) according to the need to take micropowders of different particle sizes according to weight parts to make cubic boron nitride mixture, and mix the metal powder treated in step (1) according to It is necessary to mix different types by weight to make metal powder mixture, and then mix cubic boron nitride mixture and metal powder mixture by weight to make polycrystalline cubic boron nitride tool material, cubic boron nitride See Table 2 for specific components and ratios of metal powder and metal powder;

[0034] Table 2 Component distribution ratio of PCBN tool materials

[0035...

Embodiment 3

[0042] The polycrystalline cubic boron nitride cutting tool material and preparation method of the iron casting finishing machining of the present embodiment are as follows:

[0043] (1) Put cubic boron nitride powder and metal powder into a vacuum furnace for physical vacuum treatment to remove moisture, oxygen and other impurities;

[0044] (2) Mix the cubic boron nitride micropowders treated in step (1) according to the needs with cubic boron nitride micropowders of different particle sizes according to weight parts to make cubic boron nitride mixture, and process the cubic boron nitride powders in step (1) According to the needs, different types of metal powder are mixed by weight to make metal powder mixture, and then the cubic boron nitride mixture and metal powder mixture are mixed by weight to make the raw material of polycrystalline cubic boron nitride tool material; See Table 3 for specific components and proportions of cubic boron nitride and metal powder;

[0045]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com