Folding apparatus and method

A technology of folding knife and conveying direction, which is applied in the direction of folding thin materials, binding, transportation and packaging, etc., and can solve the problems of page folding and long output time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

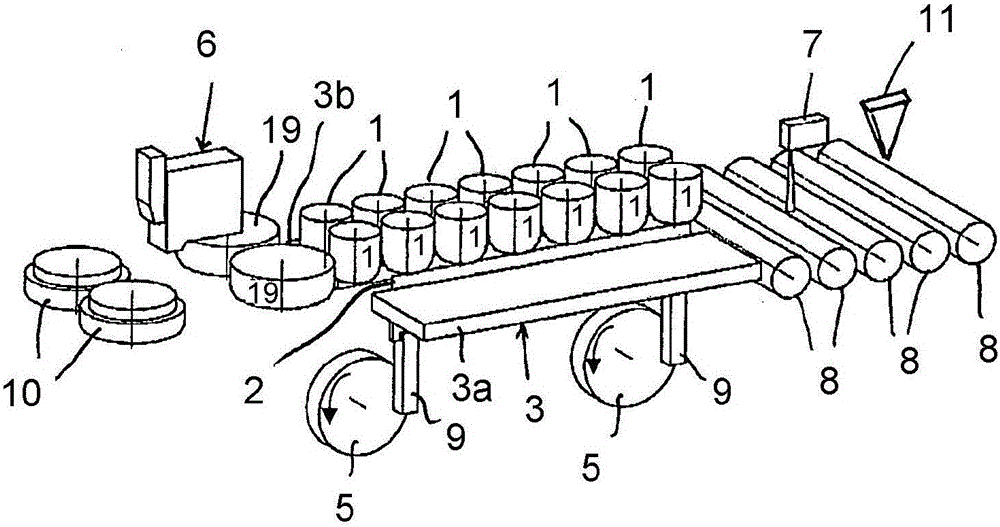

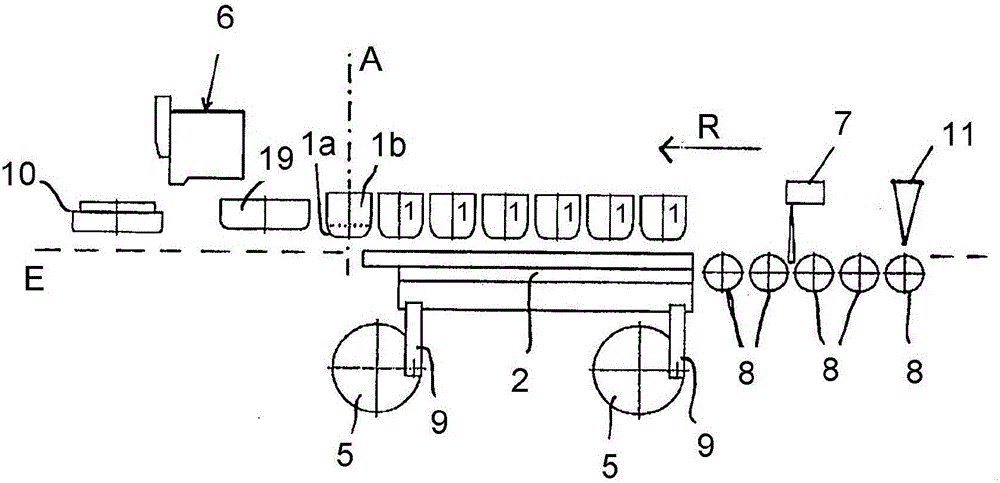

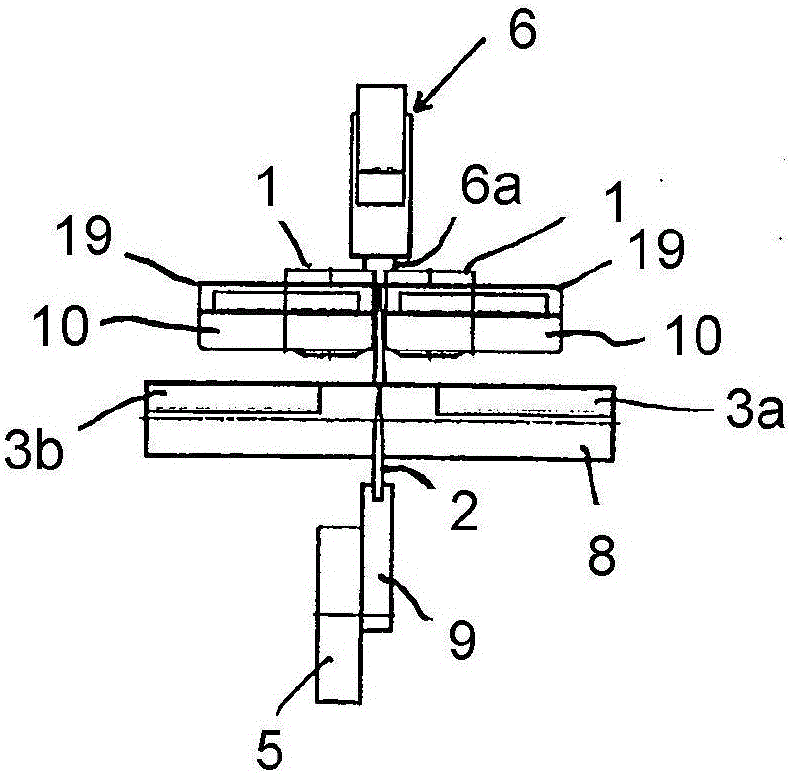

[0066] Figure 1a A schematic perspective view of the device according to the invention for folding sheets or sheet stacks is shown, but the sheets or sheet stacks are not yet shown here.

[0067] The supply rollers for sheets or sheet stacks are marked with the reference numeral 8 . A weakening device 11 for the arriving sheets or sheet stacks is arranged above the feed roller 8, which has the effect of weakening the paper before folding and thus making it easier to fold the paper fold. In this case, on the one hand, it can be a device for cutting ("scoring") along the desired folding line, or it can also be a punching device. Furthermore, there is the possibility of spraying the paper with a mark of water droplets by means of the weakening device 11 in order to achieve a temporary weakening of the paper. However, it is also possible to weaken the paper during the folding process in a suitable manner. By means of the weakening, oblique folds can be avoided in a very effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com