A mold replacing vehicle used for plastic ampoule blowing-filling-sealing three-in-one equipment

A technology of mold replacement and blow-fill-seal, which is applied in the field of plastic molding mold replacement equipment, can solve the problems of increased workload, cumbersome work process, and low work efficiency, and achieve the advantages of reduced workload, high degree of automation, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

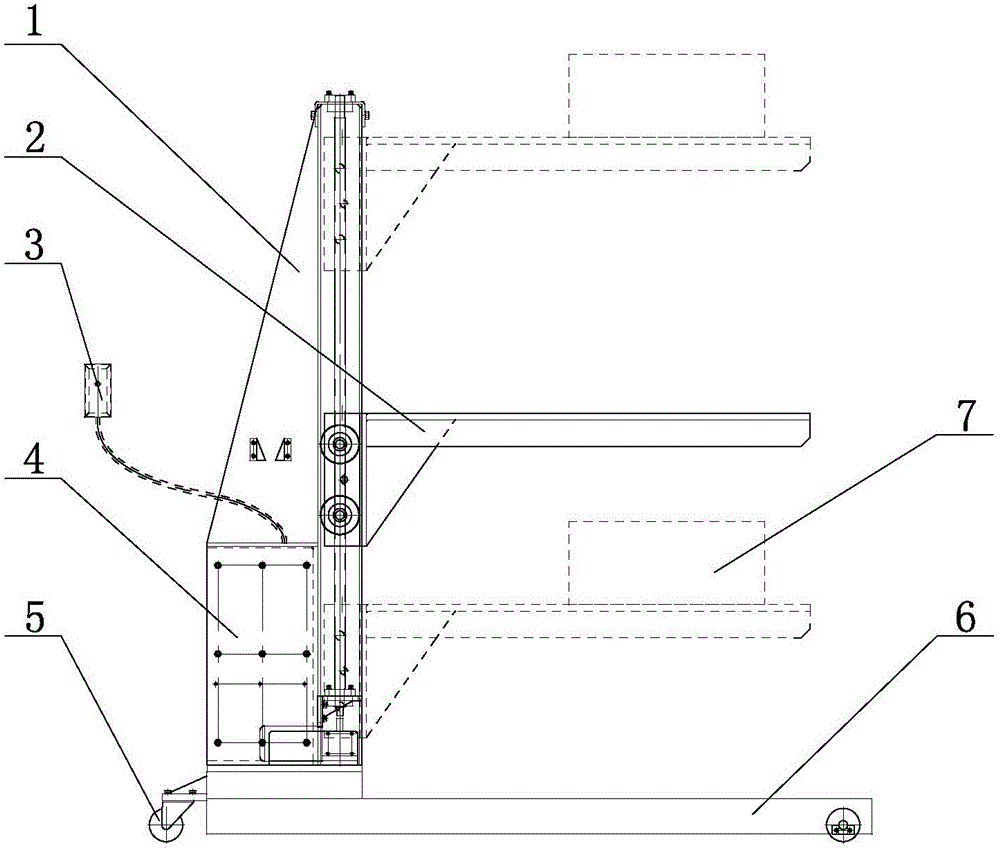

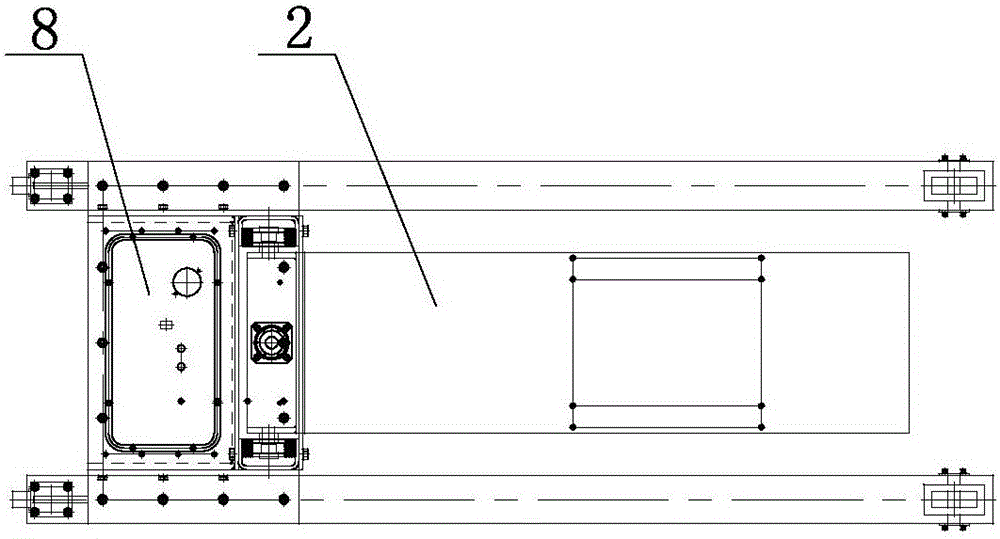

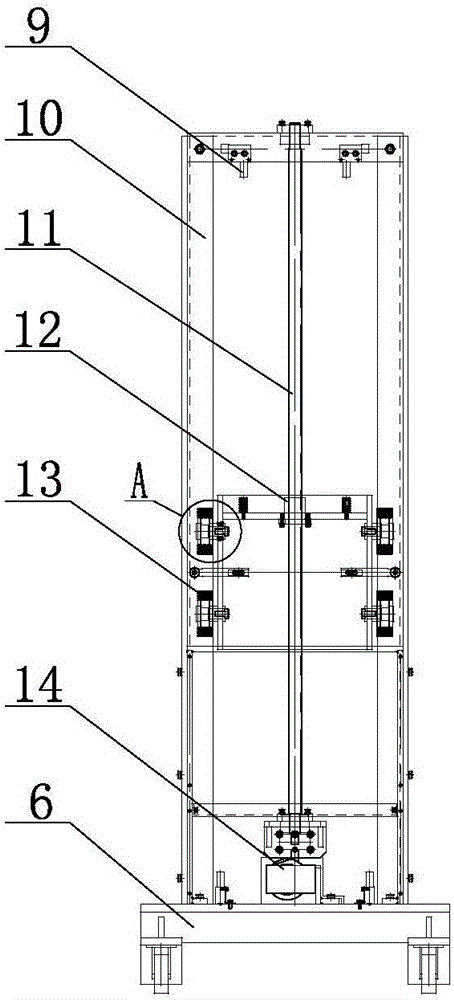

[0020] Such as Figure 1-Figure 4 As shown, the mold replacement vehicle used for plastic ampoule blowing, filling and sealing three-in-one equipment includes a moving base 6, a moving roller 5 is arranged under the moving base 6, a lifting bracket 1 is arranged on the moving base 6, and a guide slide is installed on the lifting bracket 1. rail 10 and ball screw 11, the guide rail 10 is located on both sides of the ball screw 11, the side of the lifting bracket 1 is provided with a horizontally placed lifting platform 2, the lifting platform 2 is provided with a mold mounting hole, and one end of the lifting platform 2 is provided with Lead screw nut 12 and lifting guide wheel 13, lead screw nut 12 cooperates with ball screw 11, lift guide wheel 13 cooperates with guide rail 10; Ball screw 11 lower end is connected with driving motor 14, and driving motor 14 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com