A box-type sampling shear strength test device

A technology of shear strength and testing device, which is applied in the direction of measuring device, using a stable shear force to test the strength and strength characteristics of materials, and can solve the problem of large disturbance of the clay to be tested, large error of test results, and inability to achieve horizontal positioning and other problems, to avoid the large dispersion of test data, improve the universality of application, and reduce the disturbance of soil samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the present application will be described in detail below with reference to the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

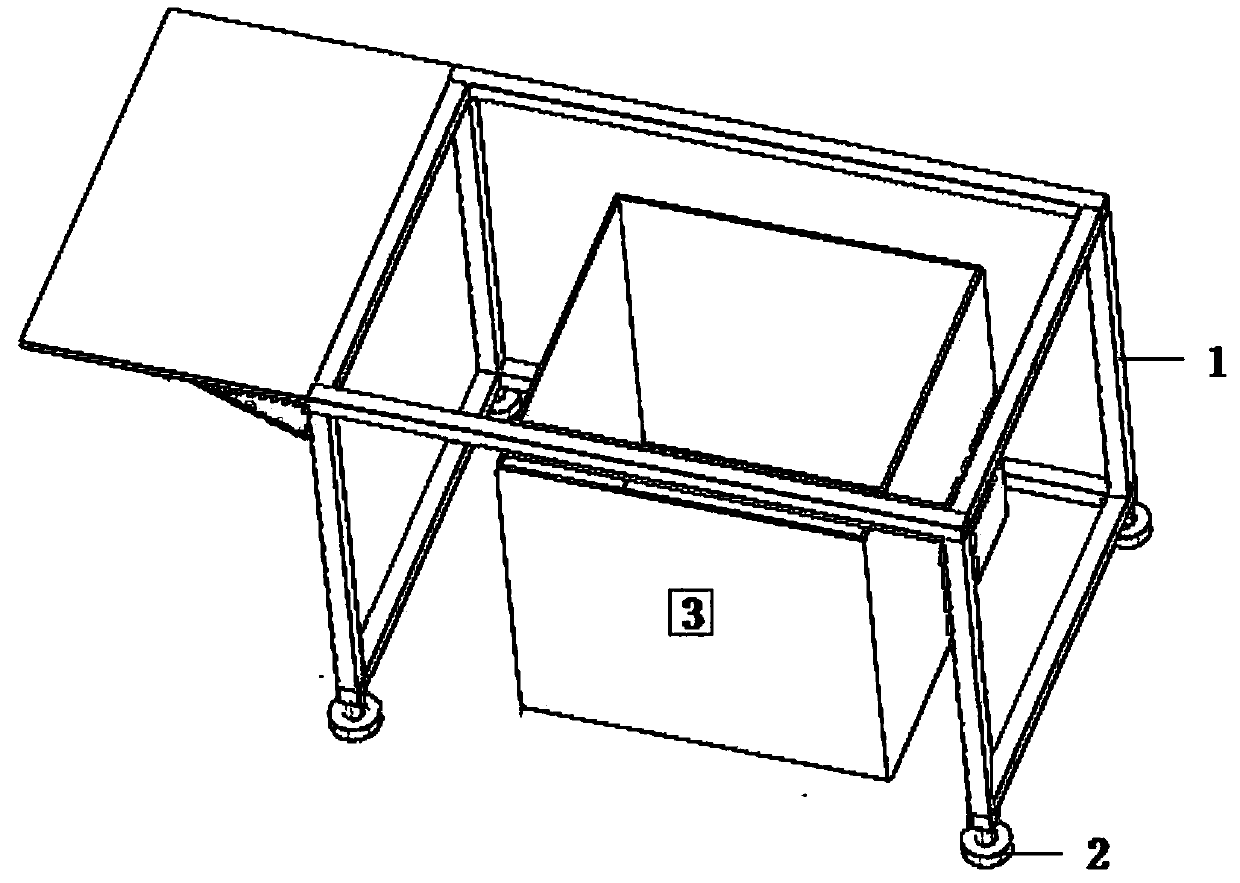

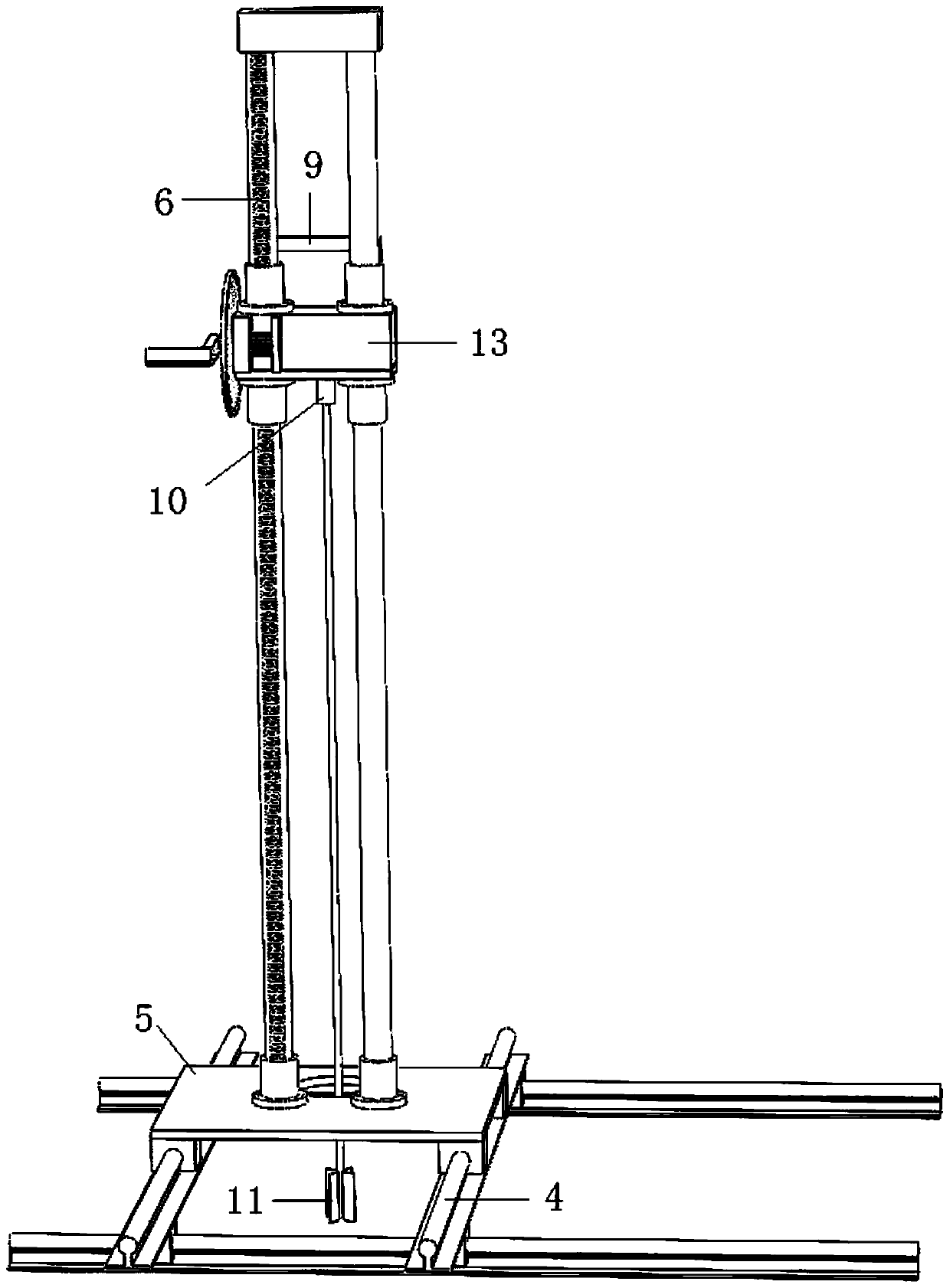

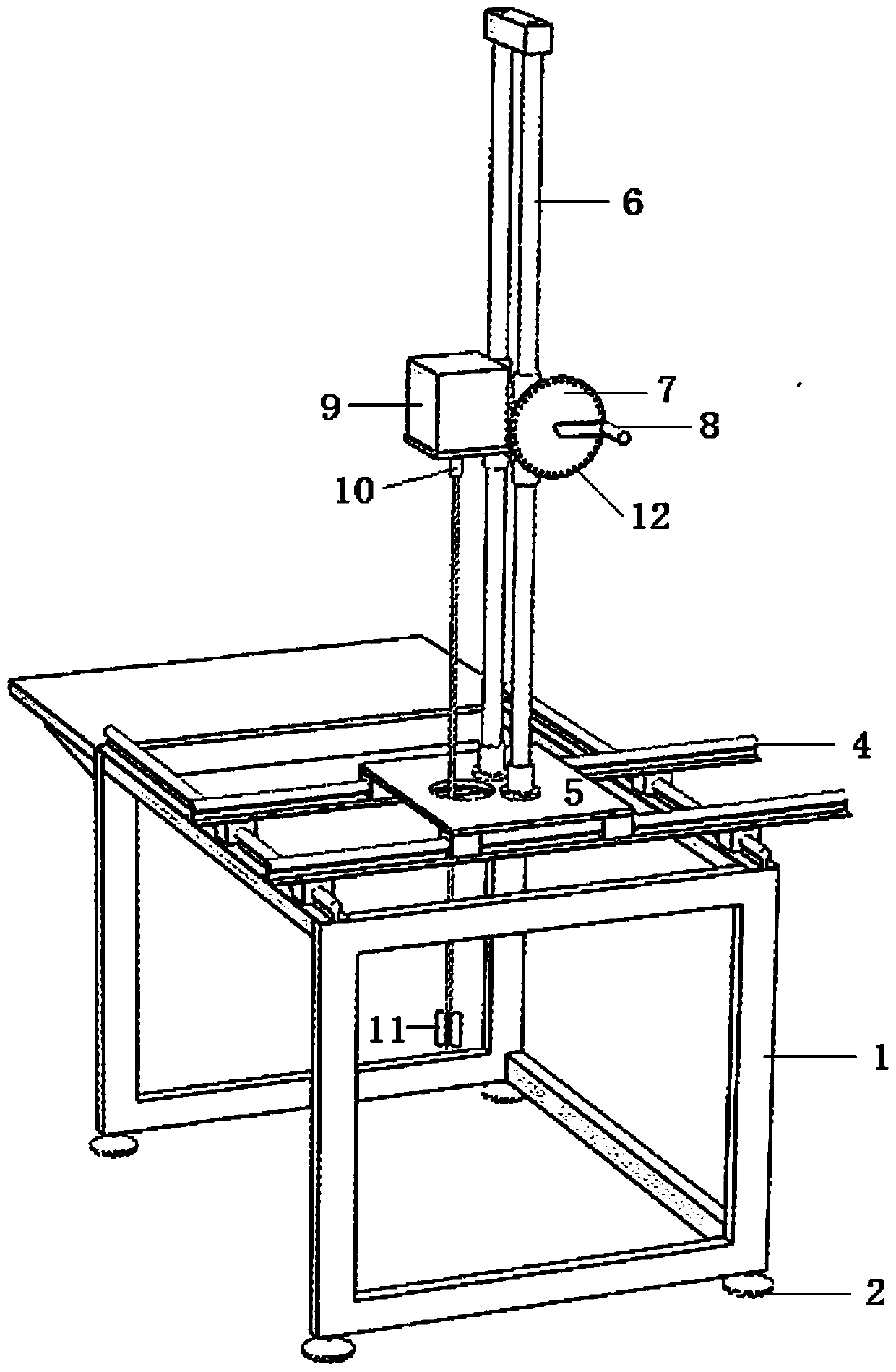

[0040] combine figure 1 , figure 2 as well as image 3 as shown,

[0041] The embodiment of the present invention provides a box-type sampling shear strength testing device, which can be provided with an equipment support 1, a driving mechanism, a positioning mechanism, and a control mechanism; cavity, the upper surface of the equipment support 1 is set to place the positioning mechanism; the driving mechanism is arranged on the positioning mechanism, the driving mechanism is provided with a cross plate test assembly, and the cross plate test assembly is set to be inserted into the clay to be tested and measure its shear strength; positioning The mechanism is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com