A high-efficiency and environmentally friendly water-based cleaning fluid for engines

An engine and cleaning fluid technology, applied in the field of high-efficiency and environmentally friendly engine water-based cleaning fluid, can solve the problems of long cleaning time, large chemical content, low efficiency, etc., and achieve the effects of short cleaning time, good cleaning effect and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

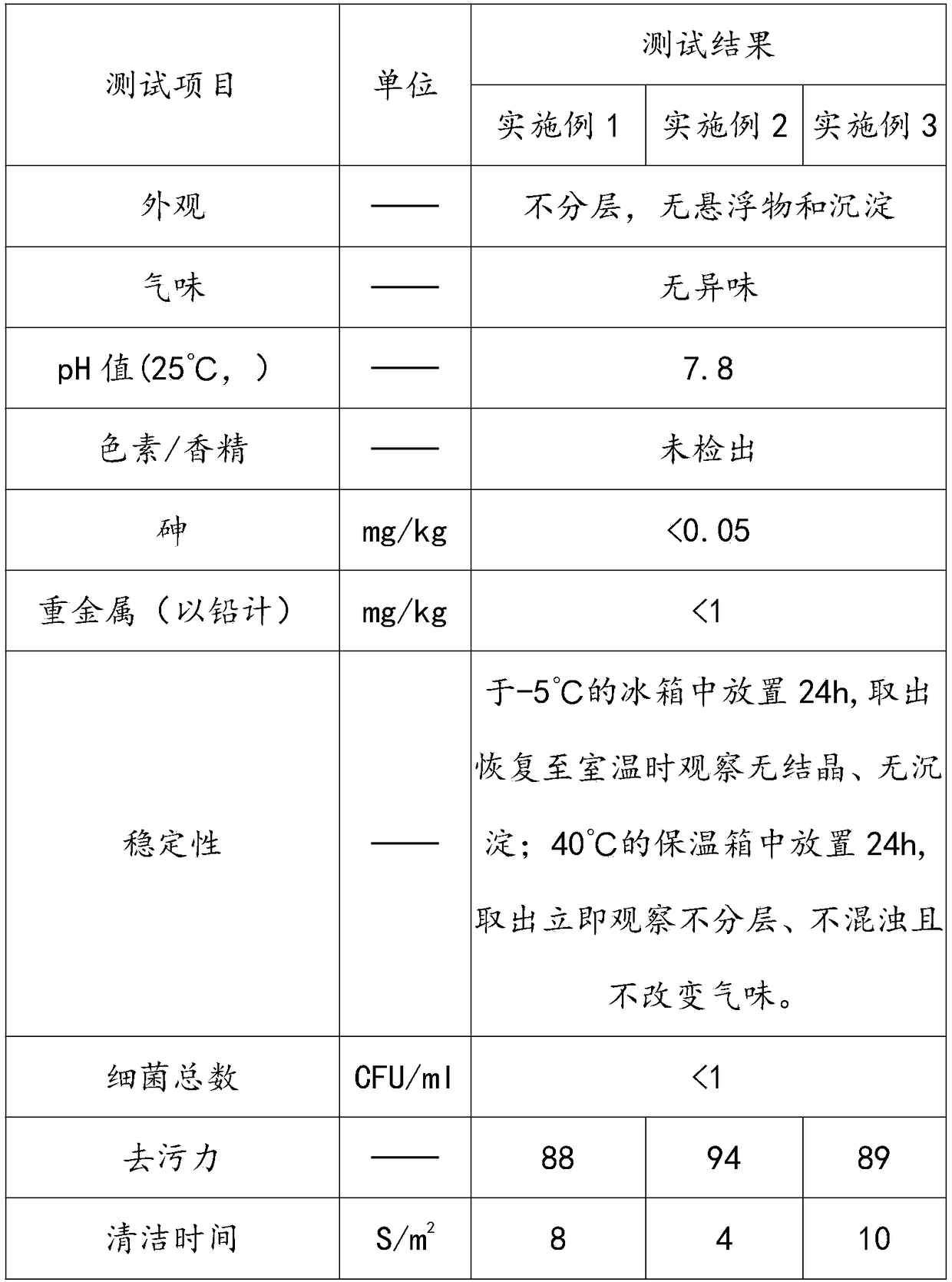

Examples

Embodiment 1

[0042] A kind of high-efficiency environment-friendly engine water-based cleaning liquid, by weight, it comprises following components and content:

[0043] 6 parts of low foaming wetting agent;

[0044] 4 parts of polyoxyethylene stearate;

[0045] 3 parts of isomeric alcohol C10 fatty alcohol ether;

[0046] 3 parts of sodium secondary alkyl sulfonate;

[0047] 3 parts of linear alkylbenzenesulfonic acid;

[0048] Cocamide MEA 1 part;

[0049] 1 part sodium xylene sulfonate;

[0050] 1 part of dodecyl dimethyl benzyl ammonium chloride;

[0051] 0.5 parts of sodium benzoate;

[0052] 0.5 parts of hydroxyethylidene diphosphonic acid;

[0053] 0.5 parts of aminotrimethylene phosphonic acid;

[0054] 1.5 parts of sodium hydroxide;

[0055] 60 parts of water.

[0056] Among them, the low-foaming wetting agent is preferably low-foaming wetting agent CF-10, the surfactant of Dow DOW TRITON, which belongs to non-ionic surfactant, transparent liquid, has excellent wettabili...

Embodiment 2

[0073] With reference to Example 1, different from Example 1, its formula is as follows:

[0074] A kind of high-efficiency environment-friendly engine water-based cleaning liquid, by weight, it comprises following components and content:

[0075] 8 parts of low foaming wetting agent;

[0076] 6 parts of polyoxyethylene stearate;

[0077] 5 parts of isomeric alcohol C10 fatty alcohol ether;

[0078] 4 parts of sodium secondary alkyl sulfonate;

[0079] 4 parts of linear alkylbenzene sulfonic acid;

[0080] Cocamide MEA 2 parts;

[0081] 2 parts of sodium xylene sulfonate;

[0082] 1 part of dodecyl dimethyl benzyl ammonium chloride;

[0083] 0.5 parts of sodium benzoate;

[0084] 0.5 parts of hydroxyethylidene diphosphonic acid;

[0085] 0.5 parts of aminotrimethylene phosphonic acid;

[0086] 1.5 parts of sodium hydroxide;

[0087] 65 parts of water.

Embodiment 3

[0089] With reference to Example 1, different from Example 1, its formula is as follows:

[0090] A kind of high-efficiency environment-friendly engine water-based cleaning liquid, by weight, it comprises following components and content:

[0091] 10 parts of low foam wetting agent;

[0092] 8 parts of polyoxyethylene stearate;

[0093] 6 parts of isomeric alcohol C10 fatty alcohol ether;

[0094] 5 parts of sodium secondary alkyl sulfonate;

[0095] 5 parts of linear alkylbenzenesulfonic acid;

[0096] Cocamide MEA 3 parts;

[0097] 3 parts of sodium xylene sulfonate;

[0098] 2 parts of dodecyl dimethyl benzyl ammonium chloride;

[0099] 1 part of sodium benzoate;

[0100] 1 part of hydroxyethylidene diphosphonic acid;

[0101] 1 part of aminotrimethylene phosphonic acid;

[0102] 2 parts sodium hydroxide;

[0103] 70 parts of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com