A kind of wnbtamov high entropy alloy and preparation method thereof

A high-entropy alloy and a single technology, applied in the field of WNbTaMoV high-entropy alloy and its preparation, can solve the problems of expensive preparation time and high energy consumption of equipment, and achieve the effect of rapid preparation and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] WO 3 , Nb 2 o 5 、 Ta 2 o 5 、MoO 3 , V powder and Al powder are fully mixed and dried to obtain thermite; the atomic molar ratio of each raw material powder in the thermite is W:Nb:Ta:Mo:V:Al=2:2:2: 2:2:14; the thermite powder is naturally loosely packed into a graphite crucible, and then the graphite crucible is placed at an acceleration of 10000m / s 2 In the supergravity field, the aluminothermic reaction is induced by electric ignition; after the reaction, the product is naturally divided into two layers, the upper layer is a porous alumina ceramic layer, and the lower layer is a WNbTaMoV high-entropy alloy with residual alumina ceramics. The WNbTaMoV Some alumina impurities remain in the high-entropy alloy. The alumina ceramics in the upper layer are peeled off to obtain the WNbTaMoV high-entropy alloy in the lower layer containing more alumina impurities.

Embodiment 2

[0036] WO 3 , Nb 2 o 5 、 Ta 2 o 5 、MoO 3 , V powder and Al powder are fully mixed and dried to obtain thermite; the atomic molar ratio of each raw material powder in the thermite is W:Nb:Ta:Mo:V:Al=2:2:2: 2:2:14; Press the thermite into a powder compact with a pressure of 35MPa, then put the powder compact into a graphite crucible, and place the graphite crucible at an acceleration of 10000m / s 2 In the supergravity field, the aluminothermic reaction is induced by electric ignition; after the reaction, the product is naturally divided into two layers, the upper layer is alumina ceramics, and the lower layer is WNbTaMoV high-entropy alloy, and a small amount of aluminum oxide remains in the upper layer of the WNbTaMoV high-entropy alloy Impurities. The alumina ceramics in the upper layer are peeled off, the alumina impurities in the upper layer of the WNbTaMoV high-entropy alloy are removed, and the lower layer of the WNbTaMoV high-entropy alloy is obtained.

[0037] Depe...

Embodiment 3

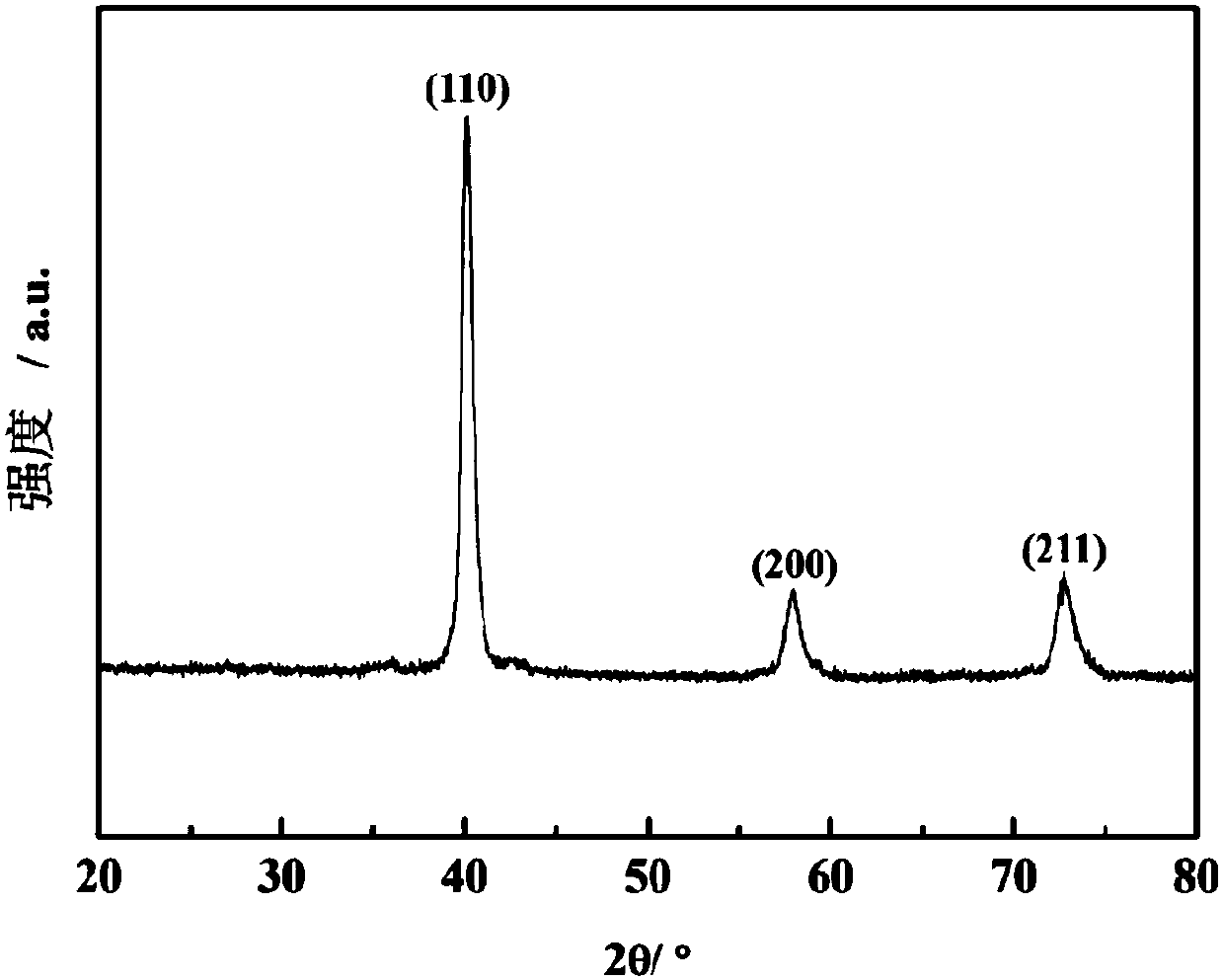

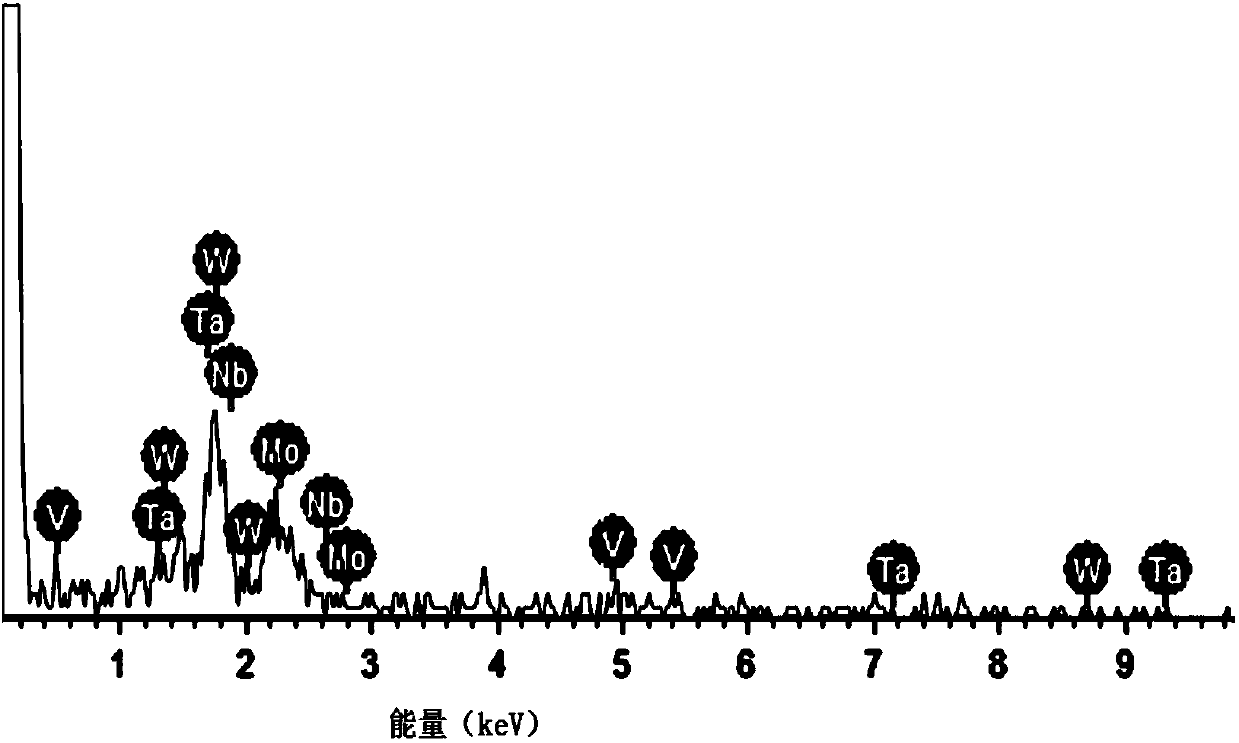

[0042] WO 3 , Nb 2 o 5 、 Ta 2 o 5 、MoO 3 , V powder and Al powder are fully mixed and dried to obtain thermite; the atomic molar ratio of each raw material powder in the thermite is W:Nb:Ta:Mo:V:Al=2:2:2: 2:2:15; Press the thermite into a powder compact with a pressure of 35MPa, then put the powder compact into a graphite crucible, and place the graphite crucible at an acceleration of 10000m / s 2 In the supergravity field, the aluminothermic reaction is induced by electric ignition; after the reaction, the product is naturally separated into two layers, the upper layer is alumina ceramics, and the lower layer is WNbTaMoV high-entropy alloy, and a small amount of aluminum oxide remains in the upper layer of the WNbTaMoV high-entropy alloy Impurities. The upper layer of alumina ceramics is peeled off, and the aluminum oxide impurities in the upper layer of the WNbTaMoV high-entropy alloy are removed to obtain the lower layer of WNbTaMoV high-entropy alloy. The crystal stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com