A hand-push conveying device applied to a construction site

A technology for construction sites and transportation devices, which is applied to trolleys, single-axis trolleys, trolley accessories, etc., and can solve problems such as potential safety hazards, cart rollovers, and impact on unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

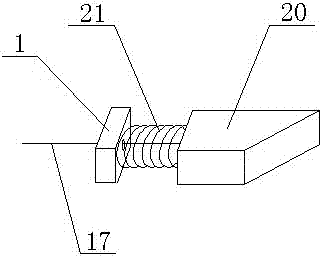

[0054] Such as Figure 1~Figure 13 As shown, a hand-push conveying device applied to a construction site described in this embodiment includes a car board 1, a car bucket 2, a single wheel 3 and a handlebar 6, and the car bucket 2 is located above the car board 1. The wheel 3 is fixed below the vehicle board 1 through the wheel board 4, the handlebar 6 is fixed on the vehicle board 1, and also includes an insertion device, a sliding device and a locking device, the insertion device is fixed on the vehicle board 1 or the handlebar 6, The sliding device is used to realize the back and forth movement of the vehicle bucket 2 on the vehicle panel 1, and the locking device is used to fix the vehicle bucket 2.

[0055] The insertion device of the present embodiment comprises a connecting rod 5, a flat plate 8 and an insertion socket 9 arranged below the flat plate 8, one end of the connecting rod 5 is fixed on the vehicle plate 1 or the handlebar 6, and the other end is fixed on the ...

Embodiment 2

[0069] Such as Figure 14 As shown, on the basis of Embodiment 1, this embodiment adds an auxiliary plate 25 and several fourth springs 26, the auxiliary plate 25 is hinged with the end of the vehicle plate 1 away from the handlebar 6, and one end of the fourth spring 26 is fixed on the auxiliary Below the plate 25, the other end is fixed on the car plate 1.

[0070] In addition, the present embodiment also includes several fifth springs 27 , one end of the fifth spring 27 is fixed on the bottom of the bucket 2 , and the other end is fixed on the auxiliary plate 25 .

[0071] The present embodiment adopts the above-mentioned structure to solve the following problems:

[0072] 1. Solve the balance problem when the cart is parked on a slope. Traditional trolleys are docked in a point-to-point manner. When the support rod as a docking support point is inserted into the soil, since the center of gravity of the goods on the trolley is not necessarily just at the center of the tro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com