Manufacturing method of high-temperature-resistant and flame-retardant PU (polyurethane) leather

A production method and high temperature resistant technology, applied in chemical instruments and methods, lamination devices, lamination and other directions, can solve the problems of no flame retardant, single use, and inability to use sofa leather, so as to avoid paint waste and ensure cleanliness. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

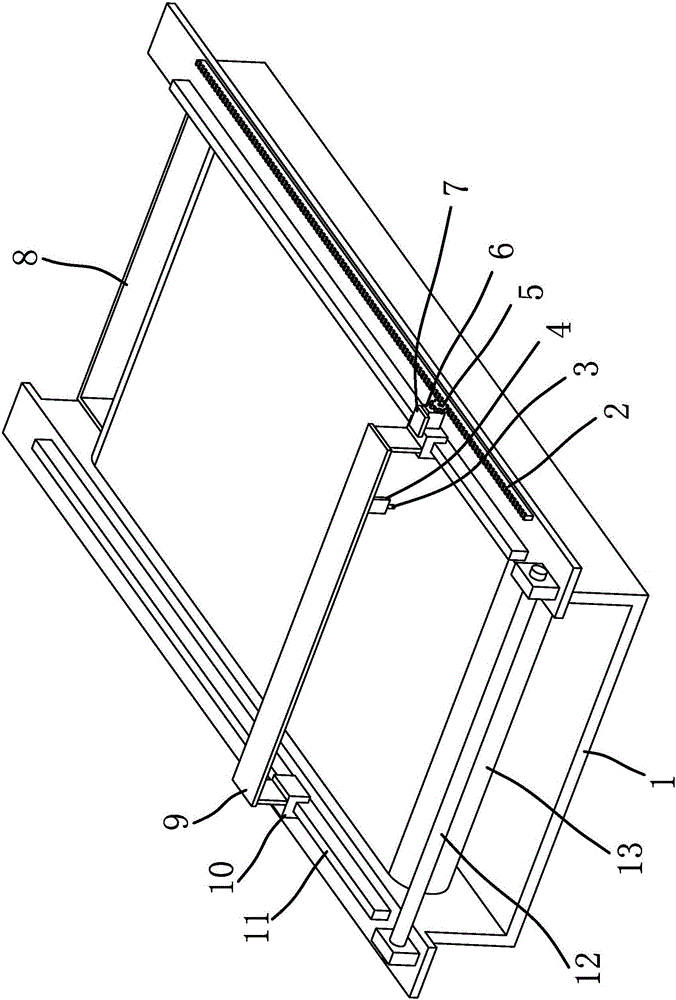

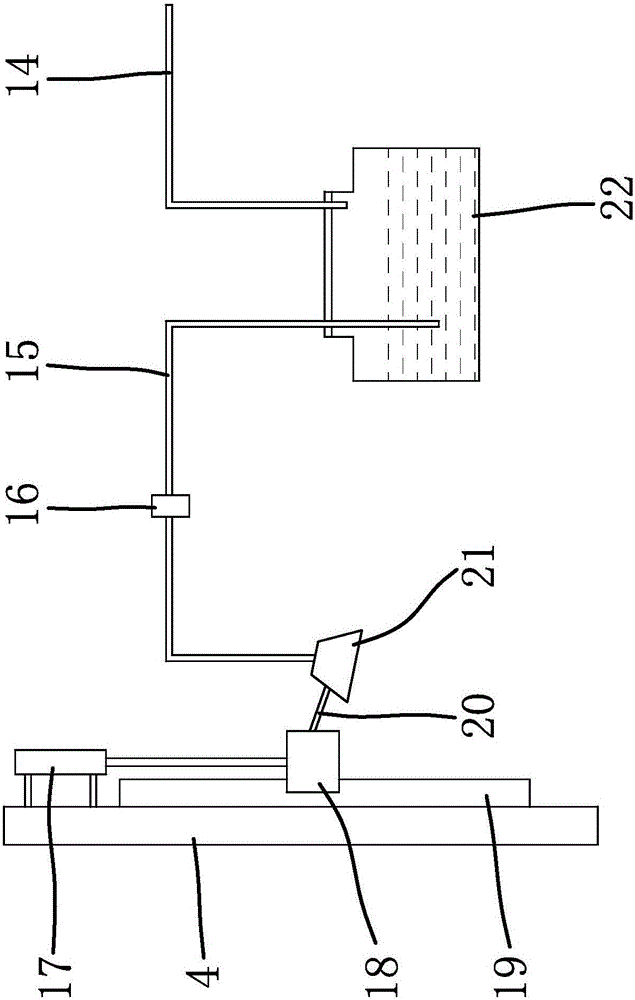

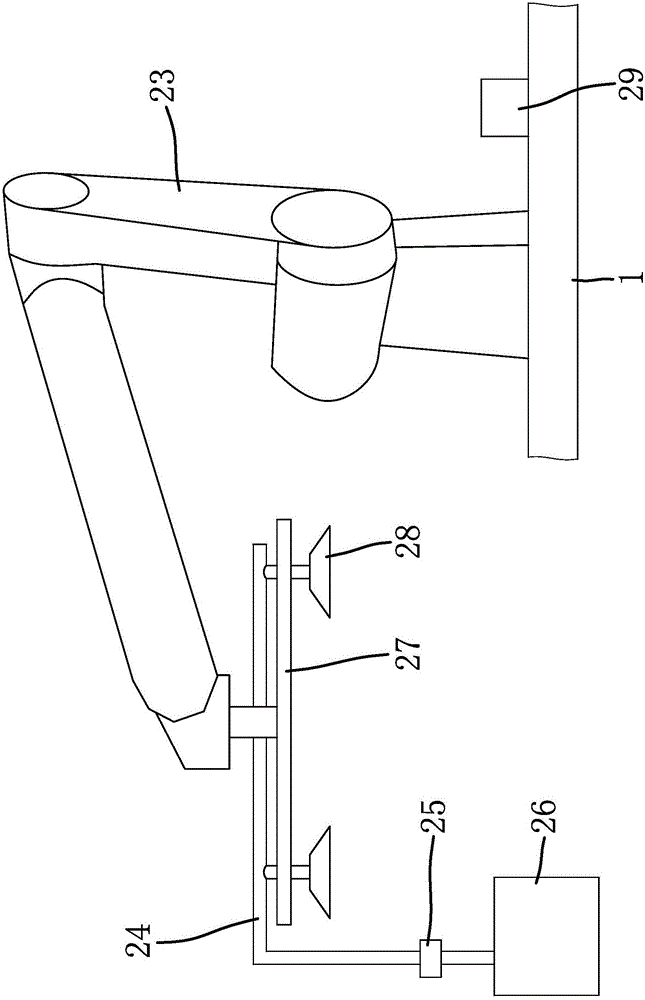

[0054] The manufacture method of the high temperature resistant flame retardant PU leather, the manufacture method comprises the following steps: a, select the base layer: select cowhide or sheepskin available on the market as the base layer, in the present embodiment, select the cowhide available on the market As the base layer; the base layer is cut into a rectangle by a cutting device; b, coating PU layer: spray one layer of PU layer on one side of the base layer by a leather spraying device, and the PU layer adopts polyurethane coatings available on the market; c, coating Flame retardant layer: apply a flame retardant layer on the other side of the base layer through a leather spraying device; d, composite: compound a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com