Valve stem and plug connections and staking tools

A technology for riveting tools and valve stems, applied in the direction of manufacturing tools, connecting components, shrinking connections, etc., and can solve problems such as loosening, misalignment of valve stem and valve plug connection, and valve stem wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

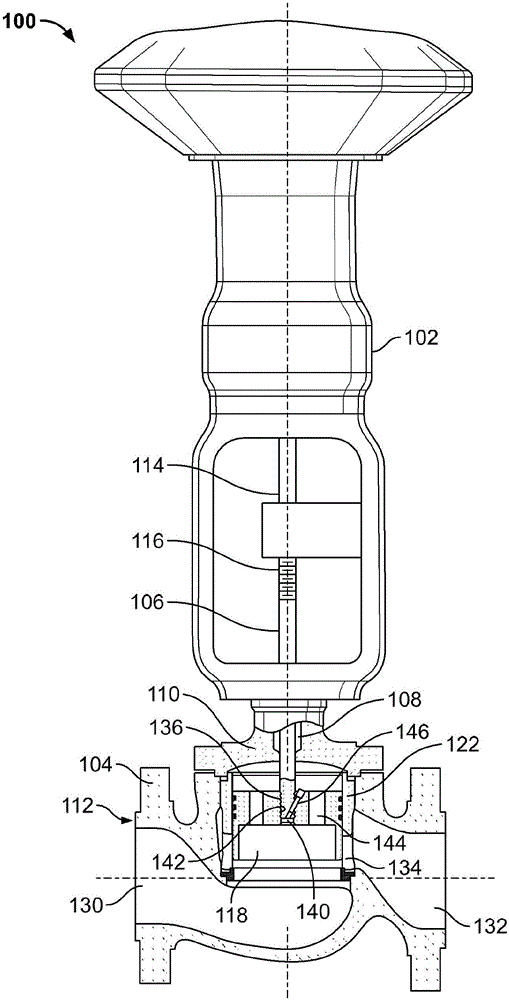

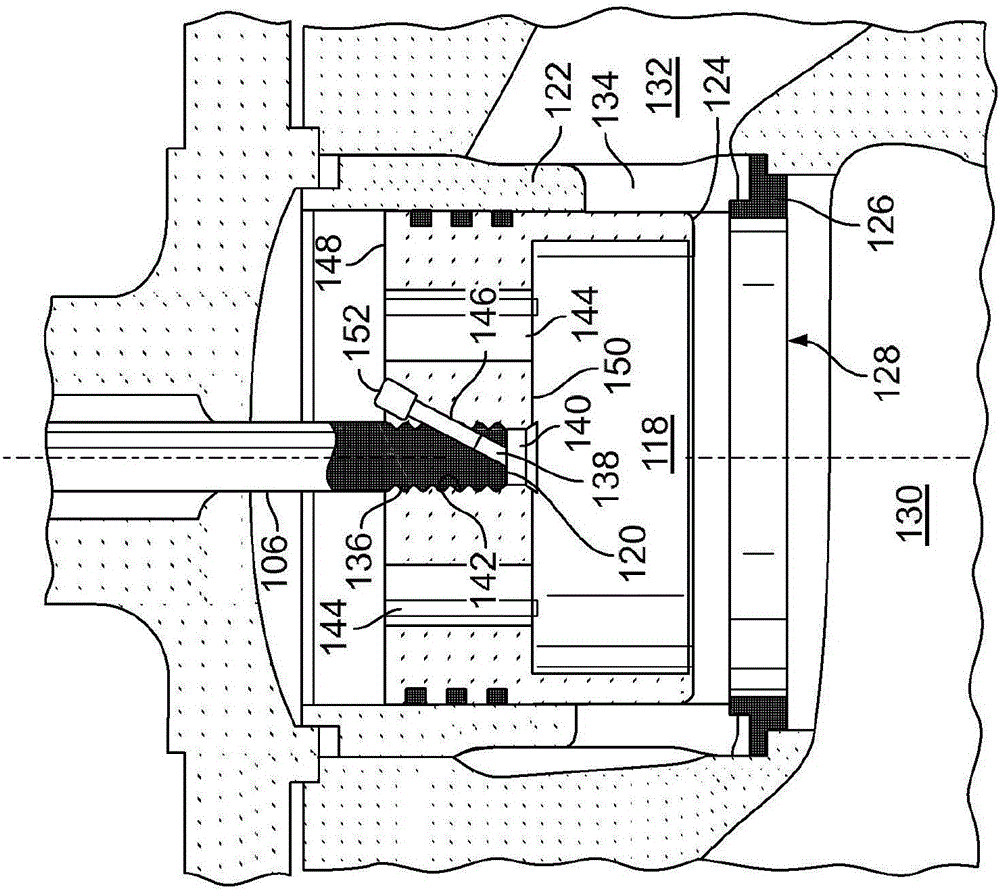

[0026] Before describing the details of the exemplary stem and plug connections and exemplary riveting tools disclosed herein, a brief discussion of known sliding stem valves is first provided in conjunction with FIGS. 1 , 2 and 3 . FIG. 1 is a partially cutaway schematic illustration of a known pneumatically actuated sliding stem valve 100 . Actuator 102 is coupled to valve body 104 and controls movement of stem 106 . Stem 106 extends through priming system 108 of bonnet 110 and into valve assembly 112 . FIG. 2 is an enlarged illustration of a portion of valve assembly 112 of FIG. 1 , including stem 106 . The valve stem 106 is coupled to the actuator rod 114 at an upper end 116 of the valve stem 106 and is coupled to a valve plug 118 at a lower end 120 of the valve stem 106 . Valve plug 118 is movable within cage 122 and includes bearing surface 124 that cooperates with valve seat 126 of orifice 128 to control the port area through which fluid may flow from inlet passage 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com